Why Choose Top Quality IBR Roofing Sheet Machine for Your Roofing Projects?

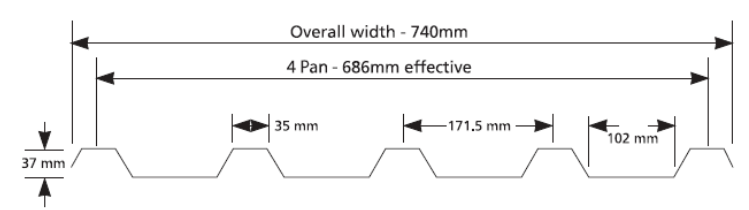

IBR, abbreviated from “Inverted Box Rib”, is one of the most popular roofing profiles in Africa, especially in South Africa. It is a square fluted roofing profile with an effective covering width of 686 mm or 890mm, designed for both side cladding and roofing applications in commercial, industrial, and residential buildings. Today let’s discuss the application and advantages about our top quality ibr roofing sheet machines.

Table of Contents

The name IBR roof sheeting has become a household term in the South African construction industry. Thanks to its deep, broad flute design, IBR sheets deliver excellent drainage characteristics, ensuring that water flows smoothly off the roof. At the same time, this unique profile provides an optimum balance between weight and load/span capacity, making it a durable and cost-effective roofing material.

With the support of advanced roll forming machine and crimping curved machine, IBR roof sheets can be factory cranked, curved, or bullnosed to match different architectural needs. This flexibility makes IBR sheets suitable not only for standard roofing projects but also for modern and customized roof designs.

Introduction to Modular Roofing & Walling Solutions in Africa

In many African markets, modular and prefabricated construction has become increasingly popular because of its fast installation, cost efficiency, and long-lasting durability. Within this context, IBR roofing sheets play a critical role as a reliable roofing and cladding option.

Traditionally, corrugated sheets and trapezoidal profiles were common in roofing projects. However, the introduction of IBR roofing sheets offered better performance in terms of water drainage, wider covering width, and stronger load-bearing capacity. Compared to corrugated sheets, IBR sheets are easier to install and require fewer sheets per square meter, reducing both labor and material costs.

This is why IBR sheet roll forming machines are in high demand — they allow local roofing manufacturers and contractors to produce high-quality IBR sheets on-site or in their factories, ensuring consistent supply for booming construction markets.

MTC – Your Reliable Partner for IBR Roll Forming Machines

For more than 15 years, MTC has specialized in the designing and manufacturing of roofing sheet roll forming machines. With advanced technology and global experience, MTC has successfully shipped its equipment to customers in Africa, Asia, South America, and the Middle East.

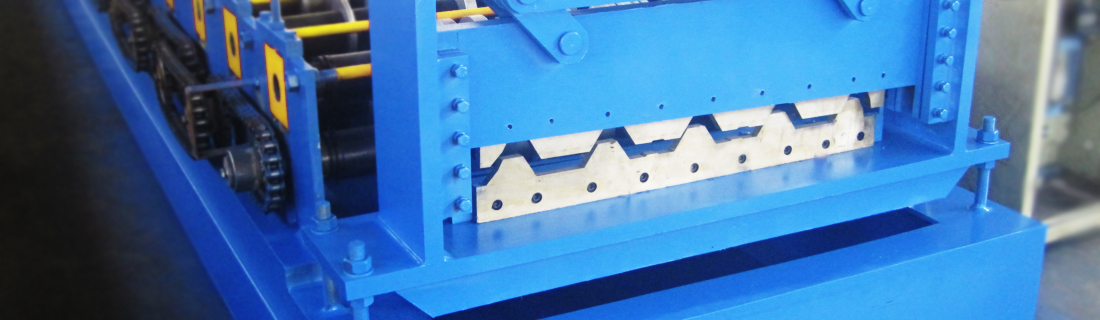

The IBR sheet roll forming machines from MTC are designed with precision engineering and durable components, ensuring long service life and consistent product output. Each machine is built to meet international standards and offers easy operation, thanks to its PLC control system.

Technical Parameters of IBR Sheet Roll Forming Machine

Below is a table highlighting the key specifications of MTC’s IBR roll forming machine:

| Parameter | Specification |

|---|---|

| Applicable Material | Galvanized Steel, Color-Coated Steel |

| Material Thickness | 0.3 – 0.8 mm |

| Effective Cover Width | 686 mm / 890 mm |

| Roller Stations | 16 steps |

| Forming Speed | 8–12 m/min |

| Main Motor Power | 5.5 kW |

| Hydraulic Power | 4.0 kW |

| Cutting System | Hydraulic cutting, Post-cut |

| Control System | PLC with touch screen (Siemens/Panasonic) |

| Forming Stands Options | Separate type or Conjoint type |

| Decoiler | Manual or Automatic (optional) |

| Machine Dimension | Approx. 8.5 m × 1.5 m × 1.5 m |

These specifications demonstrate the machine’s high efficiency, durability, and flexibility. With options to produce both 686 IBR sheets and 890 IBR sheets, the machine meets different customer demands across Africa and beyond.

Why Invest in an IBR Roofing Sheet Roll Forming Machine?

- High Market Demand – IBR sheets are the most popular roofing materials in South Africa, Zimbabwe, Namibia, Botswana, and other African countries.

- Customizable Production – The machine can produce different sheet lengths, profiles, and finishes according to project requirements.

- Durable Output – Finished sheets have strong anti-corrosion performance and excellent weather resistance.

- Fast ROI – Due to the large demand for roofing materials, investors usually see a return on investment within a short time.

- After-Sales Service – MTCprovides installation, commissioning, and operator training, ensuring buyers maximize machine efficiency.

Frequently Asked Questions (FAQs)

1. What is the effective covering width of IBR sheets?

The standard IBR profile covers 686 mm, while a larger span profile of 890 mm is also available for certain applications.

2. Can this machine produce both 686 and 890 IBR sheets?

Yes. With MTC’s IBR roll forming machine, you can produce both profiles, which are widely used in the African roofing market.

3. What type of materials can be used for IBR sheet production?

The IBR roof sheet machine can process galvanized steel, pre-painted color-coated steel, and sometimes aluminum sheets, depending on the thickness range (0.3–0.8 mm).

4. How many workers are needed to operate the IBR roll forming machine?

Generally, 2–3 workers are enough to operate the IBR sheet making machine efficiently, thanks to the automated PLC control system.

5. What is the lifespan of the machine?

With proper maintenance, MTC’s IBR sheet roll forming machine can run for 20 years or more, delivering consistent performance.

6. How fast is the production speed?

The forming speed is approximately 8–12 meters per minute, depending on sheet thickness and profile requirements.

7. Does MTC provide after-sales service abroad?

Yes. MTC provides on-site installation, commissioning, and training services worldwide, ensuring smooth startup and operation.

8. Can the IBR sheets be curved or cranked?

Yes. With the help of additional hydraulic curving equipment, IBR sheets can be curved or bullnosed to meet architectural design needs.

Ready to order? Check our 686 IBR Sheet Roll Forming Machine for Sale.

686 IBR Sheet Roll Forming Machine for Sale

The 686 IBR sheet roll forming machine is one of the most popular and widely used roll forming equipment for producing high-quality metal roofing sheets, especially in African markets. Designed with advanced forming rollers and a strong machine frame, it ensures precise profiling and consistent panel dimensions, which are critical for roofing applications. The 686 IBR profile is well-known for its strength, durability, and effective water drainage, making it suitable for residential, commercial, and industrial buildings. This machine can process galvanized steel, galvalume, or pre-painted color steel coils, offering flexibility for different customer requirements.

We build machines as per order, and the delivery time for this 686 IBR sheet machine is 60 working days!

29 in stock

Contact us for more information

If you are looking for a profitable investment in the roofing industry, the IBR sheet roll forming machine from MTC is a perfect choice. With its high precision, strong durability, and ability to produce both 686 and 890 profiles, it is well-suited for Africa’s fast-growing construction markets.

Backed by over a decade of manufacturing experience, MTC not only delivers high-quality machines but also ensures excellent after-sales service and global technical support.

So, whether you are starting a new roofing business or upgrading your existing factory, investing in an IBR sheet roll forming machine will give you a long-term competitive advantage.

[…] obey to work. Take an IBR sheet roll forming machine for example. When operator needs to produce IBR roofing sheets, two numbers are needed: Length and […]