Floor Deck Roll Forming Machine – B Deck, N Deck, 1.5″,2″,3″ Composite Deck Sheet Equipment

In the realm of modern construction, structural integrity is paramount. Floor deck roll forming machines play a crucial role in achieving this by fabricating metal deck profiles (What is metal deck?) used in flooring systems. These floor deck roll forming machines utilize advanced technology to seamlessly shape raw materials into sturdy and reliable floor decking solutions, like B deck, N deck, 1.5″, 2″ & 3″ Composite decking sheets.

In this comprehensive guide, we’ll delve into the world of steel decking roll forming machines, exploring their key features, applications across various industries, and the numerous advantages it offers.

Table of Contents

What is Metal deck?

Metal deck, also known as floor decking, is a key component in composite floor systems used in commercial, industrial, and residential buildings. Typically made of steel, metal deck serves as a structural platform upon which concrete is poured, forming a reinforced concrete slab. This composite system provides excellent strength, durability, and fire resistance, making it a preferred choice for flooring solutions in modern construction projects.

What is a Metal floor deck roll forming machine?

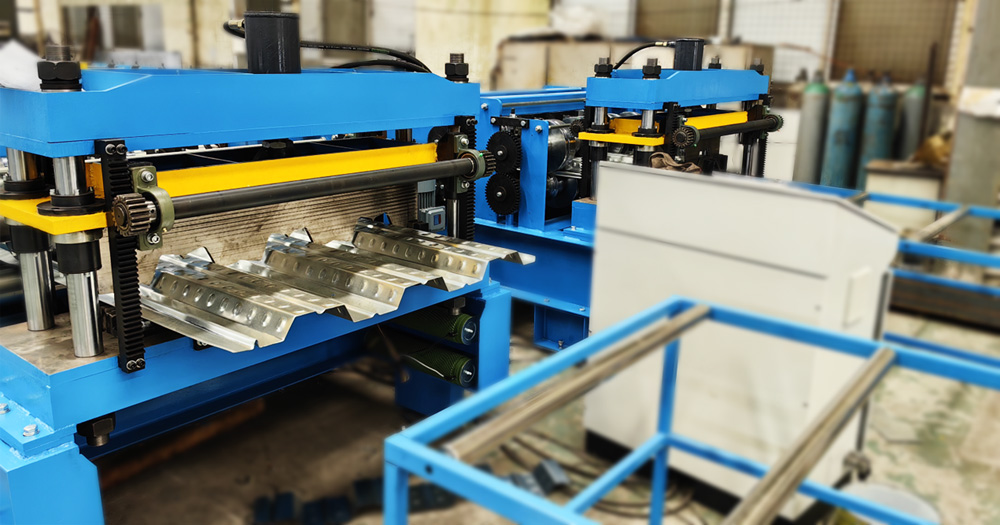

Floor deck roll forming is a specialized manufacturing process that involves shaping flat coil or sheet metal into the desired floor deck profile, and if for roof construction purpose, it will be called a roof deck roll forming machine. Floor decking roll forming machines automate this process, utilizing a series of rollers to gradually bend and form the metal into precise profiles. These machines are capable of producing a variety of floor deck profiles, each designed to meet specific structural requirements and design preferences.

By automating the process of shaping flat coil or sheet metal into precise profiles, these machines offer design flexibility, high efficiency, and cost-effectiveness, minimizing material waste and optimizing production processes. The resulting metal decking panels exhibit exceptional strength, durability, and stability, enhancing the overall structural integrity of constructions. Floor deck roll forming machines find applications in commercial, industrial, residential, and infrastructure projects, providing seamless production, design flexibility, and structural reliability. With their capacity for rapid production and short lead times, these machines are fundamental in meeting the evolving needs of the built environment.

Key Features and Components of Floor Decking Roll Forming Machines:

- Uncoiler: The uncoiler feeds the raw coil or sheet metal into the roll forming machine, ensuring a continuous supply of material.

- Roll Forming Stands: These stands consist of a series of rollers that progressively shape the metal into the desired floor deck profile.

- Embossing Rollers (Optional): Some floor deck roll forming machines feature embossing rollers that imprint patterns or textures onto the surface of the metal deck, enhancing its aesthetics and grip.

- Cut-off System: The cut-off system accurately cuts the formed floor deck profiles to the required lengths, ensuring uniformity and precision.

- Control Panel: The control panel allows operators to monitor and adjust various parameters of the roll forming process, such as speed, thickness, and dimensions.

Applications of Metal Deck in Different Industries

Metal deck finds widespread applications across various industries, including:

- Commercial Construction: Used in the construction of office buildings, shopping malls, and retail centers for elevated flooring systems.

- Industrial Construction: Utilized in warehouses, factories, and distribution centers to support heavy loads and provide durable flooring solutions.

- Residential Construction: Incorporated into residential buildings and multi-story apartments for floor decking in balconies, terraces, and parking structures.

- Infrastructure Projects: Employed in bridges, walkways, and other infrastructure projects requiring robust and long-lasting flooring solutions.

Advantages of Metal Deck Roll Forming Machines:

- Seamless Production: Floor deck roll forming machines enable the seamless production of corrugated floor decking panels, eliminating the need for additional joining or welding processes.

- Design Flexibility: These machines offer design flexibility, allowing manufacturers to produce floor decking panels in various profiles, sizes, and configurations to meet specific project requirements.

- High Efficiency: Floor deck roll forming machines operate at high speeds, ensuring rapid production and short lead times, thereby enhancing overall project efficiency.

- Cost-effectiveness: By minimizing material waste and optimizing production processes, these machines offer cost-effective solutions for fabricating metal decking panels.

- Structural Integrity: Metal decking panels produced using floor deck roll forming machines offer exceptional strength, durability, and stability, enhancing the structural integrity of buildings and structures.

Examples of Floor Decking Products:

- Type B Deck: Commonly used in commercial and industrial applications, Type B deck features a ribbed profile for enhanced strength and load-bearing capacity.

- Type N Deck: Designed for use in residential and light commercial buildings, Type N deck offers a smooth surface finish and versatility in design applications.

- Composite Deck: Combining steel deck with concrete, composite deck systems offer superior strength, fire resistance, and acoustic properties, making them suitable for a wide range of applications.

- Roof Deck: The purpose of metal roof deck products are to serve as the structural base for roofing membranes in commercial roof construction. Typically, steel roof deck is installed directly over structural steel supports to provide a working platform and to allow for the installation of insulation, weatherproofing, and other roofing materials.

In conclusion, roll forming machine floor deck plays a crucial role in the manufacturing of metal deck profiles used in composite floor systems. Floor deck roll forming machines utilize advanced technology to seamlessly shape raw materials into sturdy and reliable floor decking solutions, contributing to the structural integrity of buildings across various industries. The key features and components of floor decking roll forming machines, such as the uncoiler, roll forming stands, embossing rollers, cut-off system, and control panel, enable the efficient production of corrugated floor decking panels.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.

[…] floor deck roll forming machines operate at high speeds, allowing manufacturers to meet tight project deadlines without compromising […]

[…] steel decking roll forming machines for producing high-performance decking panels. The Losacero 25 floor deck roll forming machine is specifically designed for the American markets, including Mexico and Uruguay. Known for its […]

[…] better understand the capabilities of our floor deck roll forming machine, consider the following technical […]