Solar Mounting Frame Roll Forming Machine

As the demand for renewable energy sources continues to grow, the solar power industry has seen significant advancements in technology and equipment. Among these innovations, the Solar Mounting Frame Roll Forming Machine stands out as a pivotal development, revolutionizing the way solar panel mounting brackets are manufactured. This article delves into the features, capabilities, and benefits of this cutting-edge machine, which is designed to streamline the production process and enhance efficiency.

Advanced Features and Technology of Solar Panel Mounting Bracket Roll Forming Machine

Hydraulic Tracking Punching and Cutoff Solutions of Solar Frame Roll Forming Machine

One of the most remarkable features of the Solar panel mounting bracket Roll Forming Machine is its hydraulic tracking punching and cutoff solutions. This technology ensures that the profiles are accurately punched with holes and cut to length without stopping the roll forming process.

- Continuous Operation: The continuous nature of this operation means that there is no need to halt the machine for punching and cutting. This uninterrupted process greatly enhances production efficiency, allowing for higher output rates compared to traditional methods where the machine must stop for these operations.

- Precision and Accuracy: The hydraulic system provides high precision in both punching and cutting, ensuring that each profile is produced to exact specifications. This precision is crucial for the functionality and structural integrity of the solar mounting frames, as inaccuracies can lead to assembly issues or structural failures.

- Reduced Downtime: By integrating the punching and cutting processes into the roll forming operation, the machine minimizes downtime and reduces the need for manual intervention. This seamless integration translates to a more streamlined production process and higher overall efficiency.

Versatility in Profile Production of Solar Panel Mounting Rack Roll Forming Machine

The ability to produce two distinct profiles, 41*41 and 41*21, on the same machine is a significant advantage for manufacturers.

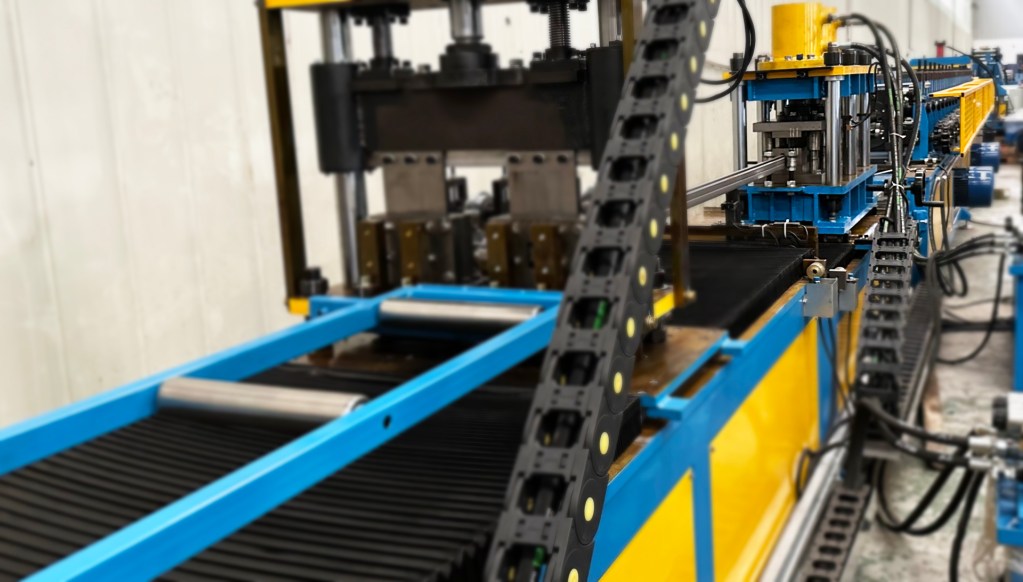

- Profile Switching: Although the solar frame roll forming machine cannot produce both profiles simultaneously, it is designed as twin roll forming structure that produces one profile on the left side and another on the right side, without changing any rollings. This flexibility allows manufacturers to meet varying customer demands and adapt to different project specifications without the need for multiple machines.

- Diverse Applications: The 41*41 and 41*21 profiles are commonly used in solar panel mounting systems, providing robust and reliable support for panels. The versatility of the machine in producing both profiles ensures that manufacturers can cater to a wide range of applications, from residential to commercial solar installations.

Component Breakdown and Their Roles

Each component of the Solar Mounting Frame Roll Forming Machine plays a critical role in ensuring smooth and efficient operation.

3T Manual Decoiler

The 3T manual decoiler is responsible for feeding the raw material into the machine. With a capacity of 3 tons, it can handle large coils of material, reducing the frequency of coil changes and minimizing material handling time. The manual operation allows for precise control over the feeding process, ensuring a consistent supply of material.

Levelling Unit

The levelling unit prepares the raw material by flattening and straightening it. This step is essential to ensure that the material enters the roll forming unit in optimal condition, which is crucial for achieving uniform and accurate profiles. Proper levelling prevents defects and inconsistencies in the final product.

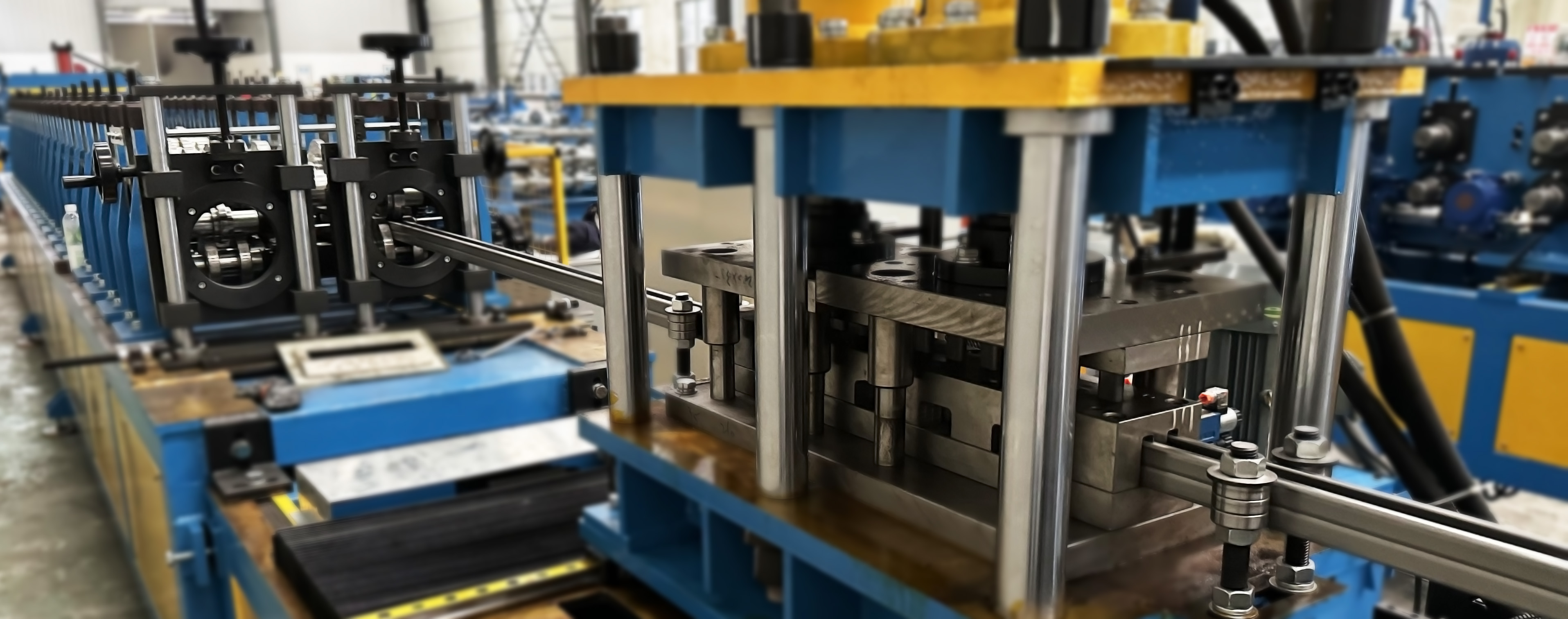

Roll Forming Unit

The roll forming unit is the heart of the machine, where the actual shaping of the material takes place. Through a series of rollers, the flat material is gradually formed into the desired profile. The precision-engineered rollers ensure that the profiles are produced with high accuracy and consistency, meeting the required specifications.

Punching Unit

The hydraulic tracking punching unit is equipped with advanced technology to create precise holes in the profiles without stopping the roll forming process. This punching unit are mounted on rails which enable the punchings to be moveable left and right. This unit ensures that the holes are accurately placed and consistently sized and punched on both solar frames, which is essential for the assembly and installation of the mounting frames.

Cutting Unit

The cutting unit, also powered by hydraulic technology, performs clean and precise cuts of the formed profiles. Working in sync with the punching unit, it ensures that the profiles are cut to the correct length without interrupting the continuous operation of the machine.

Hydraulic Unit

The hydraulic unit provides the necessary power for both the punching and cutting operations. Its reliable performance is crucial for maintaining the efficiency and precision of these processes. The hydraulic system’s strength and stability ensure that the machine operates smoothly and consistently.

Control Unit

The control unit integrates all the components and operations of the machine. It allows operators to manage and monitor the entire production process through a user-friendly interface. The control unit offers precise control over the machine’s functions, enabling quick adjustments and real-time monitoring to ensure optimal performance.

Benefits of the Solar Panel Mounting Structure Roll Forming Machine

Enhanced Efficiency and Productivity

The advanced features and seamless integration of processes in the Solar Mounting Frame Roll Forming Machine result in significantly enhanced efficiency and productivity. Manufacturers can produce higher quantities of mounting frames in a shorter time, meeting the increasing demand for solar panel installations.

By consolidating multiple processes into a single machine, manufacturers can reduce labor costs and minimize the need for additional equipment. The machine’s efficient material handling and precise forming reduce waste, leading to further cost savings. The long-term durability and reliability of the machine also lower maintenance and replacement costs.

Flexibility and Adaptability

The ability to produce two different profiles on the same machine provides manufacturers with the flexibility to adapt to varying project requirements and customer needs. This versatility allows for a broader range of applications and makes the machine a valuable asset for companies looking to diversify their product offerings.

High-Quality Output

The robust construction and advanced technology of the Solar Mounting Frame Roll Forming Machine ensure consistent high-quality profiles. The precision in forming, punching, and cutting translates to reliable and durable mounting frames that meet industry standards and customer expectations. High-quality output is crucial for the safety and performance of solar panel installations.

User-Friendly Operation

The intuitive control unit and seamless integration of processes make the machine easy to operate and monitor. Operators can quickly adjust settings, track performance, and address any issues, ensuring smooth and efficient production. The user-friendly design minimizes the need for extensive training and allows for rapid deployment in manufacturing environments.

Solar Strut Channel Roll Forming Machine

The Solar Mounting Frame Roll Forming Machine represents a significant advancement in the manufacturing of solar panel mounting brackets. Its robust construction, versatile capabilities, and advanced features make it an indispensable tool for manufacturers aiming to enhance productivity, reduce costs, and produce high-quality products. As the solar power industry continues to grow, this innovative machine will play a crucial role in meeting the increasing demand for efficient and reliable solar mounting solutions.

By combining multiple processes into a single, efficient operation, the Solar Mounting Frame Roll Forming Machine not only streamlines production but also ensures that the end products are of the highest quality. This machine is a testament to the continuous innovation and technological advancements driving the renewable energy sector forward.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.

Solar Panel Mounting Rack Roll Forming Machine, Solar Mounting Frame Equipment for Sloar Panel Mounting Bracket

The solar Mouning Frame Rol forming Machine represents a significant advancementinthe manufactuning of solar panel mounting brackets,usuay 41*41, 41*21,41'61 solar C chanels or G chanels.

Product Brand: MTC

Product Currency: USD

Product Price: 30000

Price Valid Until: 2024-08-09

Product In-Stock: PreOrder

4.99

[…] holes, and slots, enabling compatibility with a wide range of construction applications including solar panel mounting structures, steel buildings, warehouse racks, and […]