Shipped to Australia: a High-Speed Hat Purlin Roll Forming Machine

Introduction: Elevating Construction Standards

MTC, a leader in manufacturing industrial machinery, has successfully dispatched a high-speed Roof and ceiling batten machine to a construction materials supplier in Australia. Also known as the Stud Furring Channel Roll Forming Machine, Hat Channel Roll Forming Machine, Batten Roll Forming Machine for roof and ceiling, this advanced equipment promises to enhance production capabilities significantly, aligning with MTC’s commitment to innovative, high-quality solutions for the global construction industry.

Efficient and Secure Shipment

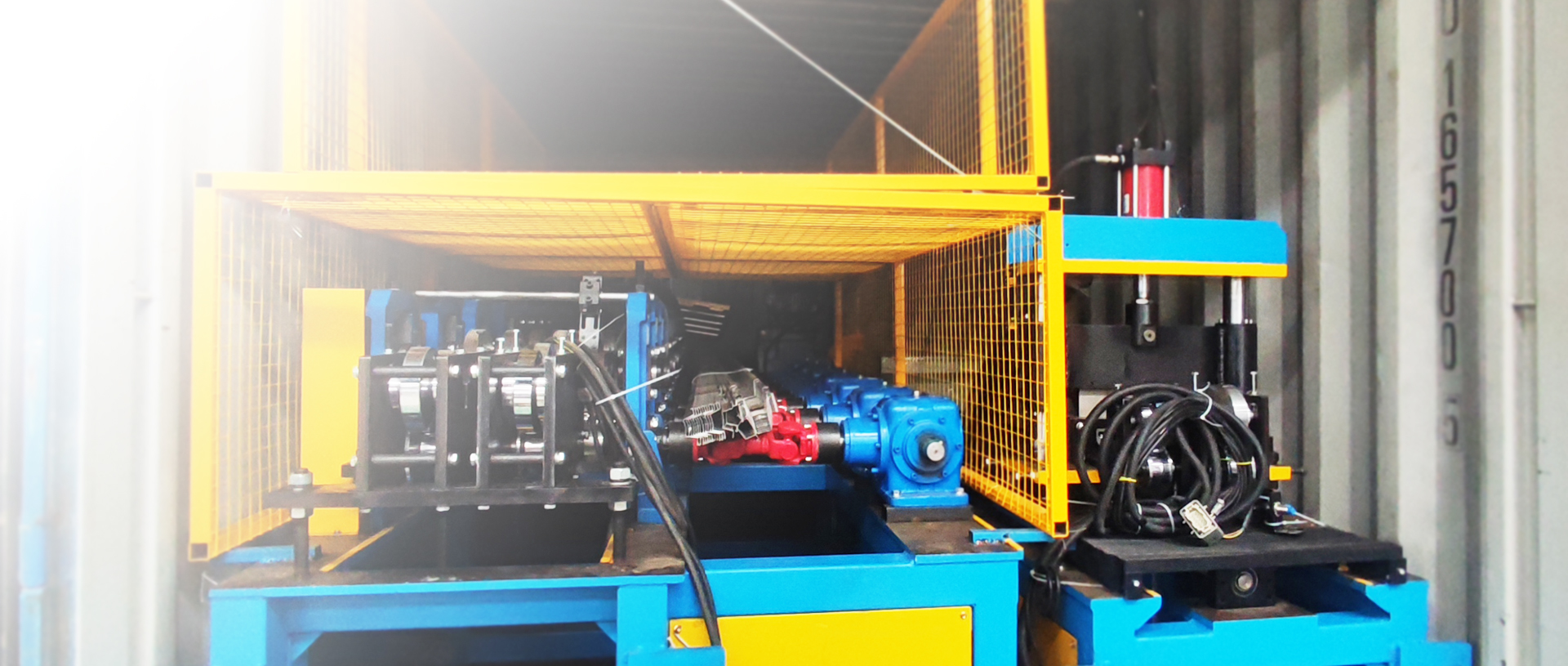

Packing and Logistics of ceiling batten roll forming machine

On April 19, 2024, MTC shipped the Hat Purlin Roll Forming Machine from its facility. The machine was meticulously packed in a custom container equipped with shock absorbers and moisture-resistant materials, ensuring it arrived undamaged and ready for use.

Journey to Australia

The furring channel roll forming machine, transported via sea freight, is destined for the Port of Perth. MTC’s logistics team ensured compliance with international shipping standards, emphasizing timely and safe delivery. This careful planning highlights MTC’s dedication to providing a reliable and efficient shipping process.

Installation and Integration

Upon arrival, MTC’s technicians will oversee the installation, ensuring the machine’s quick integration into the client’s production line. The support package includes on-site training and comprehensive manuals, facilitating a seamless transition to operational use.

Key Features of the Roof Batten Roll Forming Machine

High-Speed Production

The high-speed Hat Purlin Roll Forming Machine, recently shipped by MTC to Australia, represents a significant leap forward in the efficiency and productivity of construction material manufacturing.

Capable of producing up to 40 meters of hat purlins, furring channels, and hat channels per minute, this advanced machine is designed to meet the demanding requirements of the modern construction industry.

One of the standout features of the Hat Purlin Roll Forming Machine is its remarkable production speed. Traditional roll forming machines often struggle to keep pace with the rapid timelines of large-scale construction projects.

In contrast, MTC’s machine operates at an impressive rate, allowing for the swift fabrication of essential structural components. This speed not only accelerates project timelines but also significantly reduces labor costs, making it an invaluable asset for any construction materials supplier.

Versatile Multi-Profile Production of hat channel roll forming machine

The hat channel roll forming machine can produce various profiles, including hat purlins, furring channels, and hat channels, with quick changeover between profiles. This versatility is crucial for manufacturers with diverse production needs, enhancing productivity and reducing downtime.

Precision and Quality of hat purlin roll forming machine

Equipped with high-grade steel rollers, the machine ensures consistent, high-quality output. Advanced control systems allow for precise adjustments, maintaining stringent quality standards across production runs and ensuring reliable performance.

Automated and User-Friendly Operation of furring channel roll forming machine

Featuring a PLC (Programmable Logic Controller) system, the machine offers automated roll forming, reducing manual intervention and minimizing error risks. The user-friendly touch screen interface provides real-time monitoring and control, simplifying operation and maintenance.

Material Flexibility and Energy Efficiency

The machine can process various materials, including galvanized steel, aluminum, and stainless steel, in thicknesses from 0.5mm to 2.0mm. This flexibility makes it suitable for a range of construction applications. Additionally, its energy-efficient design supports sustainable practices, reducing power consumption and operational costs.

Enhanced Safety Features

MTC prioritizes safety, equipping the machine with emergency stop functions and protective guards to ensure a secure working environment for operators.

Impact on the Australian Market

Boosting Production Capabilities

The deployment of MTC’s high-speed Hat Purlin Roll Forming Machine in Australia marks a pivotal moment in enhancing the production capabilities of our esteemed partner in the construction materials industry. This advanced machinery brings substantial benefits that directly address the growing demands and challenges faced by Australia’s booming construction sector.

The roof and ceiling batten roll forming machine is designed to operate at speeds of up to 40 meters per minute, making it a formidable asset for accelerating production timelines. This increased speed significantly boosts manufacturing efficiency, allowing our Australian partner to meet tight project deadlines and scale operations according to market demands. By reducing production lead times and enhancing throughput, the machine enables quicker turnaround on orders and supports the timely completion of construction projects across the country.

One of the machine’s key strengths lies in its versatility. It can seamlessly switch between producing various profiles such as hat purlins, furring channels, and hat channels with minimal downtime. This adaptability not only caters to diverse customer needs but also ensures operational flexibility. Whether it’s for residential, commercial, or industrial applications, the ability to produce multiple profiles enhances our partner’s capability to supply a wide range of construction projects with tailored solutions.

Supporting Local Projects and Economic Growth

By enabling local production of high-quality purlins and channels, the machine reduces reliance on imports, leading to cost savings and ensuring a steady supply for ongoing construction projects. This supports timely project completion and contributes to the development of Australia’s infrastructure, while also creating new job opportunities and stimulating economic growth in the local manufacturing sector.

Promoting Sustainable Practices

The machine’s energy-efficient design aligns with Australia’s commitment to sustainability. It supports environmentally friendly manufacturing practices by reducing energy consumption, thus contributing to the industry’s shift towards more sustainable production methods.

A Step Towards Efficiency

The successful shipment of the high-speed Hat Purlin Roll Forming Machine to Australia marks a significant milestone for MTC and its Australian partner. This advanced machinery is set to revolutionize the production of construction materials, aiding the rapid development and modernization of Australia’s construction industry. MTC remains dedicated to delivering cutting-edge solutions and unparalleled service, fostering progress and innovation in the global manufacturing landscape. We look forward to the positive impact this machine will have on Australia’s construction industry and beyond.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.