Metal Fabrication Equipment Adapts to Green Manufacturing Standards

As global environmental regulations tighten and industries face increasing pressure to reduce carbon emissions, the metal fabrication sector is undergoing a fundamental transformation. Metal fabrication equipment manufacturers and production facilities alike are rethinking every stage of the fabrication process — from coil processing to forming and finishing — to achieve cleaner, more energy-efficient operations.

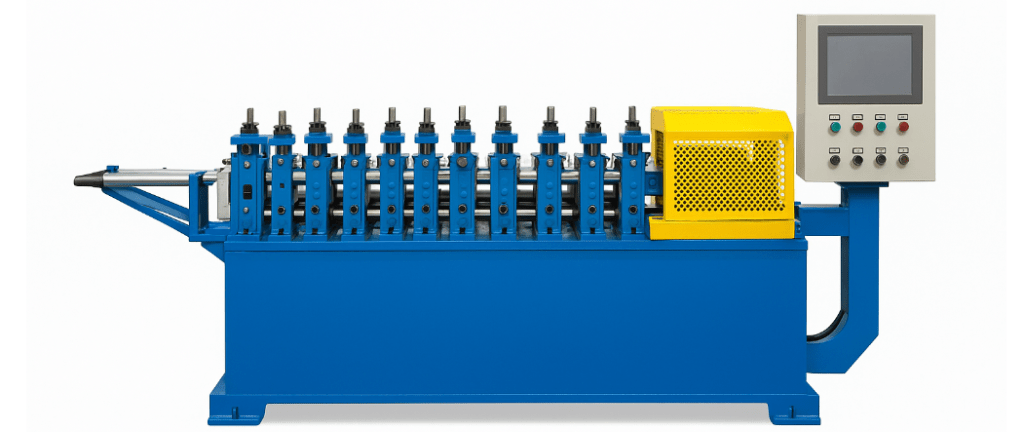

In the world of roll forming machines and metal fabrication equipment, sustainability no longer means compromising productivity. Instead, advanced automation, smarter energy use, and material optimization are helping manufacturers meet green manufacturing standards while maintaining competitive output levels.

Table of Contents

Environmental Efficiency Becomes a Core Design Principle

Energy consumption in metal fabrication has long been dominated by heavy hydraulic systems, continuous coil feeding, and high-speed cutting processes. In response, new-generation equipment builders are designing roll forming lines that consume less power and generate less waste.

Examples of Eco-Friendly Design Innovations

- Variable-speed drives (VSD): Motor power adjusts automatically to match forming load, minimizing energy waste during idle or low-demand phases.

- Servo-hydraulic systems: Replace traditional hydraulic units with servo-controlled pumps that operate only when pressure is required.

- Energy recovery systems: Capture and reuse kinetic energy during deceleration phases.

- Closed-loop lubrication: Reduces oil consumption and prevents fluid contamination.

The PU Sandwich Panel Production Line from MTC Industrial (Shanghai) is a practical example of such innovation. Its modern hydraulic unit and optimized cutting mechanism help reduce oil temperature rise and energy consumption, ensuring stable operation with lower power demand — a crucial improvement for continuous production plants.

From Coil to Product: Minimizing Material Waste

Sustainability in roll forming starts long before cutting begins. Coil processing and line layout play a major role in material utilization. By optimizing feed length and coil width, manufacturers can reduce scrap by up to 5–8%, translating directly into cost and energy savings.

Advanced coil processing lines now incorporate real-time monitoring of coil consumption and thickness deviation. Combined with high-precision servo feeders, these systems ensure every millimeter of raw material is efficiently converted into usable product.

In addition, computer-aided nesting software helps determine the most efficient cutting sequences for custom profiles. When integrated into the sheet metal production line, this software minimizes leftover edges and short cuts, significantly improving sustainability performance.

Cleaner Production Through Digital Monitoring

Digitalization is a powerful ally in green manufacturing. Sensors and smart controllers allow operators to monitor temperature, pressure, and speed data throughout the roll forming process.

When connected to factory networks, this data helps identify inefficiencies in energy use or raw material feeding. Machine learning tools can even predict upcoming maintenance needs, preventing unplanned shutdowns that consume extra energy during restarts.

At MTC Machinery, digital control platforms are being developed to enable cloud-based energy tracking. This function allows users to view power consumption trends for each motor and drive component, making it easier to implement continuous improvement programs for greener production.

Recycling and Sustainable Materials in Metal Fabrication

The environmental impact of metal fabrication extends beyond machinery. Material choice is becoming equally important. Manufacturers are now using coils made from recycled steel or aluminum, which drastically reduces carbon emissions compared to virgin metal.

Modern roll forming equipment is designed to handle these recycled materials — often softer or more variable in thickness — without compromising dimensional accuracy. Servo-driven roll stands adjust pressure automatically to accommodate such variations.

The construction industry, one of the largest consumers of roll formed products, increasingly demands recyclable and corrosion-resistant materials for roof panels, facades, and purlins. This has driven demand for sustainable metal forming lines that can process galvanized, pre-painted, or aluminum-zinc coated coils efficiently.

Future Outlook: Sustainability as a Competitive Advantage

The green transition is reshaping how companies evaluate their equipment suppliers. Buyers are increasingly prioritizing machine builders who demonstrate commitment to sustainable innovation.

MTC Industrial continues to expand its portfolio of environmentally conscious solutions, including energy-efficient roll forming machines and automatic decoiler systems that optimize coil usage.

In the near future, sustainability metrics — such as energy consumed per ton of product — will likely become standard performance indicators in the metal fabrication industry. Companies that invest early in efficient, data-driven production lines will be better positioned to meet both regulatory and market demands.

Key Takeaways

- Energy-efficient motors and servo-hydraulic systems reduce power consumption.

- Optimized coil-to-product flow minimizes material waste.

- Smart sensors enable continuous monitoring and predictive maintenance.

- Recycled materials are gaining acceptance in roll forming applications.

- Sustainable design now drives purchasing decisions in metal fabrication.

About MTC Industrial:

MTC Industrial (Shanghai) designs and manufactures a complete range of metal fabrication equipment, including roll forming machines, coil processing systems, and PU sandwich panel production lines. With a focus on automation, energy efficiency, and environmental compliance, MTC supports manufacturers worldwide in achieving greener and more sustainable production.