Customer Visits to Explore C Shaped Solar Channel Roll Forming Machine

Recently, MTC Machinery welcomed a professional delegation from the United Arab Emirates to our factory. The visit focused on exploring our C shaped solar channel roll forming machine, gaining insight into our production capabilities, technological expertise, and quality management systems.

Table of Contents

Customer Impressed by MTC Machinery’s Expertise

From the start, the UAE customer expressed admiration for MTC Machinery’s extensive experience in research, development, and manufacturing of cold-formed roll forming equipment. They were particularly impressed by:

- High-precision mold machining ensuring consistent profile quality

- Advanced production management maintaining efficiency and delivery timelines

- Innovative engineering solutions for solar panel frame manufacturing

The delegation recognized that MTC Machinery combines decades of experience with modern automation and precision engineering, making it a reliable partner for solar mounting system production, particularly strut channel roll forming machine.

Production Needs: C-Shaped Profiles for Solar Panel Frames

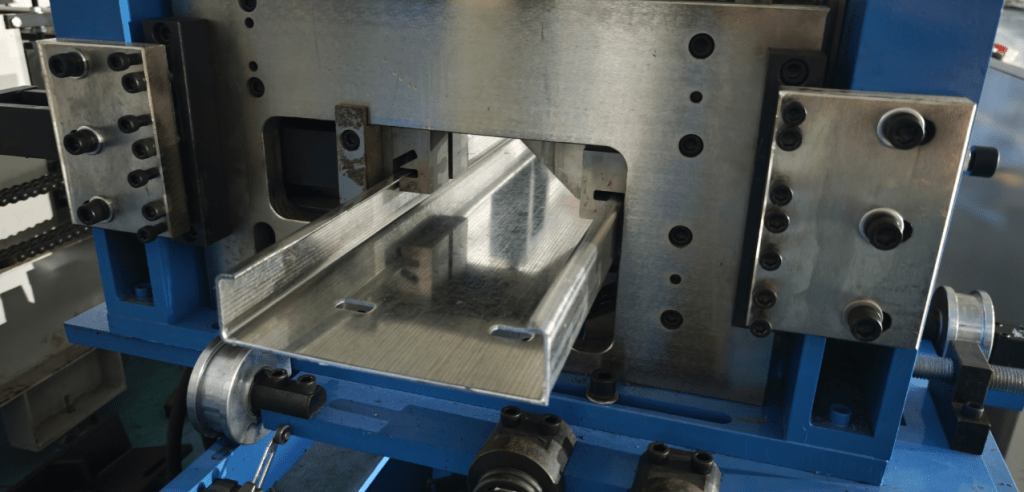

The UAE client plans to produce C-shaped profiles with a thickness of 1.5–3 mm, specifically for supporting frames of solar panel mounting systems. During the factory tour, our technical team demonstrated:

- Automatic Profile Change – rapid, tool-free switching between different C-profile sizes

- Stepless Cutting – precise, automated cutting for profiles of any length

- Customizable Punching Solutions – options tailored to technical requirements and budget

These features highlight our machine’s flexibility and ability to meet modern solar industry production needs.

Advanced Features of Our C Shaped Solar Channel Roll Forming Machine

1. Automatic Profile Change

Our unistrut channel roll forming machine allows seamless switching between multiple profile sizes. This reduces downtime and increases productivity, which is crucial for manufacturers producing a variety of solar mounting frames.

2. Stepless Cutting

The stepless cutting system ensures each profile is cut accurately and consistently, eliminating manual adjustments and improving production efficiency.

3. Custom Punching Options

We provide various punching solutions to meet customer-specific requirements. Whether for mounting brackets, wiring channels, or drainage holes, our machine delivers precision and flexibility.

Why MTC Machinery is a Preferred Partner

During the visit, the UAE client evaluated not only our equipment but also our company’s overall capabilities:

- Expertise in C shaped channel Roll Forming Machines – decades of experience in solar panel frame production

- Precision Mold Manufacturing – ensuring uniform dimensions and structural reliability

- High-Level Automation – maximizing productivity with minimal labor

- Flexible Solutions – customizable punching and profile options

- Comprehensive Support – guidance from pre-sales consultation to after-sales service

The customer expressed that these advantages align perfectly with their production goals, making MTC Machinery a strong candidate for future collaboration.

Positive Feedback from the UAE Delegation

The client expressed appreciation for:

- Our R&D capabilities and innovative design

- The quality of our equipment and precision machining

- Our production management system and workflow efficiency

They indicated that they would discuss internally and follow up with us after returning to the UAE. Their intention to potentially choose MTC Machinery as their equipment partner was clear, emphasizing confidence in our technology and services.

A Strong Step Toward Collaboration

The UAE client’s visit highlighted MTC Machinery’s commitment to quality, innovation, and customer satisfaction. Our C-shaped solar panel mounting frame roll forming machine combines precision, automation, and customization, making it ideal for producing high-quality solar panel supporting frames. With strong technical expertise and professional guidance, MTC Machinery is well-positioned to support solar manufacturing clients globally.

FAQs About C-Shaped Solar Channel Roll Forming Machine

1. What thickness range can the machine handle?

Our machines produce C-shaped profiles from 1.5 mm to 3 mm, suitable for solar panel supporting frames.

2. Can the machine produce multiple profile sizes automatically?

Yes, it features automatic profile change, allowing rapid switching without manual tooling adjustments. See more at our C/Z quick change roll forming machine.

3. Does the machine support custom punching?

Absolutely. We provide flexible punching solutions to meet project specifications and budget.

4. What is stepless cutting?

Stepless cutting allows profiles to be cut at any length automatically, ensuring precision and repeatability.

5. How precise is the mold machining?

Our molds are manufactured to high precision standards, ensuring consistent dimensions and smooth surfaces.

6. Can MTC Machinery provide production guidance?

Yes, we offer full support for setup, operation, optimization, and maintenance.

7. Is the machine suitable for large-scale production?

Definitely. Automation, rapid profile change, and efficient cutting make it ideal for high-volume solar frame production.

8. How is the best punching option determined?

Our technical team consults with clients to choose the most suitable solution based on production requirements and budget.