Window Frame Roll Forming Machine | Full Auto Line Passes FAT & Ready to Ship

We are proud to announce that our latest window frame roll forming machine has successfully passed its Factory Acceptance Test (FAT) and is now sitting ready for shipment to our esteemed client. This fully automatic production line represents a new benchmark in the manufacturing of steel window and door frames, with a highly sophisticated setup that combines speed, accuracy, and reliability.

Designed with the demands of modern window and door manufacturers in mind, this cutting-edge windows frame roll former integrates advanced controls, precise punching mechanisms, and a smooth production flow—making it an ideal choice for producing rectangular steel window frames with exacting standards.

Table of Contents

Key Features of the Window Frame Roll Forming Machine

This automatic roll forming line is built for performance. It processes galvanized steel coils with a thickness ranging from 0.3mm to 0.5mm, transforming them into ready-to-assemble rectangular window frames with minimal manual intervention. The entire production line includes:

- 2-in-1 Decoiler & Leveller

- Punching Unit with Servo Feeder

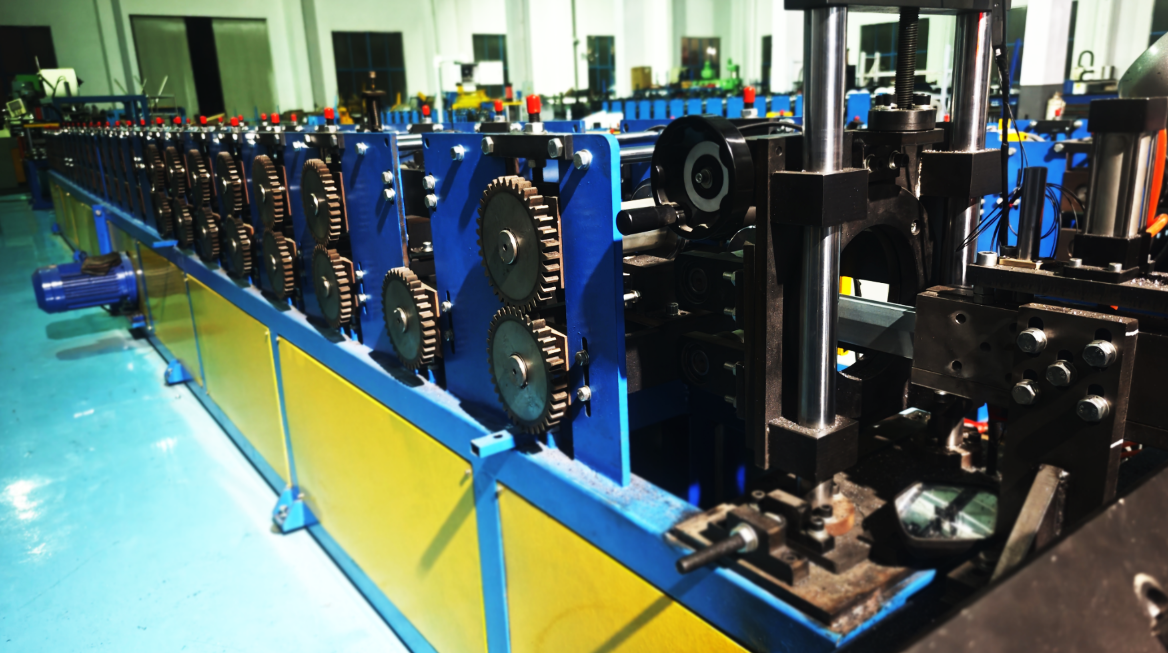

- Roll Forming Machine

- 45-Degree Precision Cutoff System

- Dual PLC Control Units

Each component works seamlessly together, ensuring that the frame profiles are produced with consistently high quality and dimensional accuracy.

Technical Specifications

| Item | Specification |

|---|---|

| Material | Galvanized Steel |

| Material Thickness | 0.3mm – 0.5mm |

| Decoiler | 2-in-1 Automatic with Leveling Function |

| Feeding System | Servo Feeder |

| Punching System | Hydraulic Punching with Servo Control |

| Roll Forming Stations | 26 stations |

| Roller Material | GCr15 Steel, Hard Chrome Coated |

| Transmission | Chain Drive (Gear-box optional) |

| Cutoff System | 45-Degree Flying Saw Cutoff |

| Cutting Control | Independent PLC for Cutoff |

| Punching Control | Separate PLC for Punching |

| Production Speed | 10–15 meters per minute (cutting not included) |

| Output Profile Type | Window / Door Frame Profiles (Rectangular) |

| Power Requirement | 380V, 50Hz, 3 Phase (customizable) |

| Line Dimension (approx.) | 20m x 2m x 1.8m (L x W x H) |

Precision Door Frame Production with 45-Degree Cutoff

What sets this windows frame roll former apart is its unparalleled hole punching and cutting precision. The punching unit, driven by a high-speed servo feeder, ensures each hole and slot is placed exactly where it needs to be along the profile. But the real technical challenge lies in the 45-degree cutoff system.

The machine is engineered to cut exactly between the holes and slots, so that the integrity of the window frame is preserved, and the final profile can be assembled into a perfectly rectangular window frame. This level of precision requires advanced calculation, alignment, and motion coordination—achieved through dual PLC control systems.

One PLC governs the punching system, ensuring holes and slots are punched in sync with the profile’s feed speed and programmed distances. The second PLC manages the cutoff unit, allowing the blade to descend at precisely the right moment between punched zones.

This dual-control approach eliminates overlap, preserves structural integrity, and ensures that all punched elements fall in line with design requirements.

Structural and Operational Highlights

2-in-1 Decoiler and Leveller

The production line begins with a robust decoiler that holds steel coils and feeds them smoothly into the leveller. The leveller removes any coil memory, flattening the material for optimal punching and forming.

Servo Feeder and Hydraulic Punching

The punching unit, equipped with precision molds and servo-driven feeding, handles multiple hole and slot patterns. Its flexibility allows manufacturers to adapt hole distances and layouts based on customer needs without retooling the entire line.

Roll Forming Machine

The galvanized steel window frame machine consists of a carefully calculated number of forming stations, each contributing to the gradual transformation of flat sheet into a shaped profile. Side guides and rollers ensure the shape is maintained throughout the process, preventing warping or deviations.

Precise Hole-Positioning System

The machine is equipped with a precise hole-positioning system. When punching is not required, it can accurately measure and cut the material to the exact length. When punching is enabled, the system ensures holes are positioned at a precise distance from the cut ends, fully meeting customer specifications. This guarantees both dimensional accuracy and functional reliability for applications such as window frames, doors, or other steel structures requiring exact hole placement relative to the cut.

45-Degree Cutoff Saw

One of the line’s most remarkable features, the 45-degree flying cutoff saw, ensures a smooth, angled cut between holes and slots. This enables the automatic formation of a mitered corner joint, a crucial aspect for clean and tight window or door frame assembly.

Smart Dual PLC System

The integration of two PLC units—each dedicated to a specific function—provides the operator with independent yet synchronized control. This not only boosts precision but also allows quick troubleshooting and minimal downtime.

Applications of Safety Door Frame Roll Former

The profiles coming off this window frame roll former line are ready for direct use in window and door assembly. With holes and slots perfectly aligned and angled cuts accurate to the millimeter, the frames can be joined into rectangular windows or doors with no need for post-processing or correction. This results in time savings, better aesthetics, and stronger finished products.

Moreover, the adjustable settings make this production line ideal for producing custom window or door frames, whether they are residential safety door frames, commercial aluminum window frames, or steel interior partitions.

Galvanized Steel: A Durable Raw Material

Using 0.3mm–0.5mm galvanized steel, this machine ensures corrosion resistance and long-term durability for the final frame product. These frames are widely used in:

- Residential and commercial window systems

- Safety door structures

- Steel partition frameworks

- Prefabricated and modular construction systems

By combining high-quality materials with high-precision manufacturing, this door frame roll forming machine offers manufacturers a competitive edge in today’s fast-paced construction and fabrication industries.

Safety Door Frame Roll Former: Ready for Shipment

Having passed all FAT inspections—including profile accuracy, hole placement, cut position, production speed, and safety controls—the machine is now sitting in our warehouse, awaiting its final packing and logistics process. Every sensor, motor, and blade has been thoroughly tested to ensure smooth performance at the client’s site.

Before shipment, the machine will be securely packed with rust-proof wrapping, reinforced wooden cases, and labeled component parts for easy installation. Detailed documentation and remote support will be provided to ensure a hassle-free commissioning.

Contact Us for Your Next Roll Forming Machine

This windows frame roll forming machine is not just a piece of equipment—it’s a smart manufacturing solution that combines automation, customization, and quality. Its sophisticated punching and cutoff technology ensures every frame meets strict standards, while its user-friendly control system enables efficient operation and minimal downtime.

Whether you’re in the market for a door frame roll former, window profile machine, or safety door frame roll forming machine, this production line offers a scalable, reliable, and precise option for your frame fabrication needs.

Looking for a reliable windows frame roll forming machine? Contact us today for a customized solution!

[…] For more information about the window frame roll forming machine and how it can improve your production process, please visit the product page:👉 https://mtc-china.com/window-frame-roll-forming-machine/ […]

[…] part. Normally it happends on narrow profiles, for example the C/U purlin roll forming machine, windows frame roll forming machine, hat purlin roll forming machines etc. However, for the production of wide sheet, like the metal […]