How MTC’s Roll Forming Solutions Empower Prefabricated Construction

In recent years, the global construction industry has undergone a paradigm shift. Developers and contractors are increasingly embracing prefabricated construction methods for faster delivery, improved quality control, and reduced environmental impact. This evolution has dramatically increased demand for precision steel components—everything from PU insulated wall panels to lightweight steel framing systems.

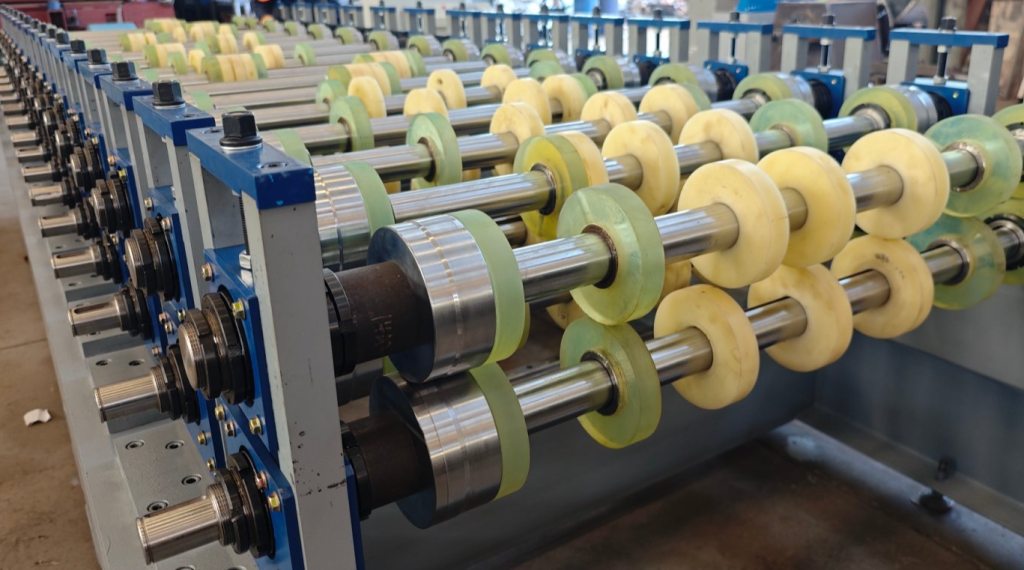

At the heart of this transformation is roll forming technology, and MTC’s roll forming solutions are playing a vital role in powering this change across multiple countries and industries.

Table of Contents

What Makes Roll Forming Solutions Essential in Prefab Construction?

Cold roll forming machines enable the mass production of consistently precise, long-length steel profiles. Whether you’re building modular hospitals, quick-assembly homes, or commercial warehouses, roll formed products are essential due to:

- Speed: Continuous production allows output of hundreds of meters per hour.

- Precision: Tolerance accuracy is often below ±0.5 mm.

- Strength-to-Weight Ratio: Optimized profiles reduce structural weight while maintaining strength.

- Compatibility: Profiles are designed for fast assembly—ideal for prefab.

MTC’s machines are engineered to deliver exactly these benefits—tailored for the prefab sector.

🏭 Our Key Products for the Prefab Industry

1. PU Sandwich Panel Production Line

PU sandwich panels are widely used in prefabricated buildings for walls, roofs, and cold rooms. MTC’s automated PU sandwich panel line supports continuous lamination with precise PU injection, foil feeding, and cutting.

Applications:

- Prefab house wall and roof panels

- Cold storage rooms

- Mobile container buildings

- Cleanrooms and industrial halls

Advantages:

- Excellent thermal insulation (λ ≤ 0.022 W/m·K)

- Fire resistance (up to B1 / B2 standard)

- Lightweight but structurally rigid

- Fast installation with interlocking systems

2. Roll Forming Machines for Structural Profiles

MTC manufactures custom roll forming machines for profiles such as:

- C/U/Z purlins

- Stud and track framing

- Hat and omega channels

- Ridge caps and roof battens

- Unistrut channels

- C/U solar channels

These form the steel skeleton of most prefabricated structures, ensuring load-bearing capacity and dimensional accuracy.

3. Decorative and Insulated Wall Panels

In addition to functional cladding, MTC also provides solutions for decorative PU insulated wall panels—designed with embossed patterns or fluted surfaces for aesthetic exterior walls. These panels serve both thermal insulation and architectural needs.

📐 Engineering Flexibility for Every Project

MTC doesn’t offer one-size-fits-all solutions. Every prefab project has its own requirements—whether it’s a containerized school in Africa or a large-scale modular hotel in Europe.

We provide:

- Custom machine configurations (width, thickness, speed)

- Support for local standards (UL, CE, ISO)

- Touchscreen-controlled PLC systems with auto error alerts

- Online and onsite technical training for international clients

🌍 Global Projects in Prefabrication

MTC roll forming equipment has been used by customers across:

- India: Portable steel shelters and military barracks

- South America: Mobile clinics and school buildings

- Southeast Asia: Cold chain warehouses and panelized homes

- Middle East: PU roof sandwich panels for prefabricated mosques and site offices

We work hand in hand with prefab builders, EPC contractors, and government project suppliers to deliver localized solutions using globally trusted machinery.

💡 Why Choose MTC for Prefab Solutions?

| Feature | MTC Advantage |

|---|---|

| Years in Roll Forming | Over 20 years of experience |

| Product Types | Roll formed sheets & Structural profiles |

| Automation Level | Fully PLC-controlled with auto cutting, stacking |

| Customization | Machines tailored to your panel or profile design |

| After-sales Support | Remote diagnostics + overseas engineer dispatch |

We’re not just selling equipment—we deliver entire roll forming solutions for prefab systems.

🔭 Looking Ahead: Green, Fast, Modular

The construction world is shifting to modular, sustainable, and digitally enabled processes. MTC is well-positioned to support this change with innovations like:

- Eco-friendly PU foaming systems

- Integration with robotic stacking and packing

- Flexible lines supporting both PU roof sandwich panels and PU insulated wall sandwich panels

🔄 Building the Future with Precision Steel

Prefab construction is not a trend—it’s a necessity in today’s fast-paced and resource-conscious world. Behind every modular wall or insulated roof panel is a roll forming solution that makes it possible.

At MTC, we’re proud to build the machines that build the future. Whether you’re launching a new prefab housing initiative or scaling your sandwich panel production, we are here to deliver engineering excellence, speed, and support.

🟩 Want to Learn More?

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of roll forming solutions, including various metal forming related equipment in China.