Fully Automated Quick Change CZ Purlin Roll Forming Machine Revolutionizing Steel Construction

After 75 days of meticulous design and manufacturing, we are proud to announce our latest innovation. The Quick Change CZ Purlin Roll Forming Machine has successfully completed its pre-shipment test. It is now ready for delivery. This advanced equipment represents a significant leap forward in the purlin manufacturing industry. It sets a new benchmark for automation, efficiency, and versatility.

Table of Contents

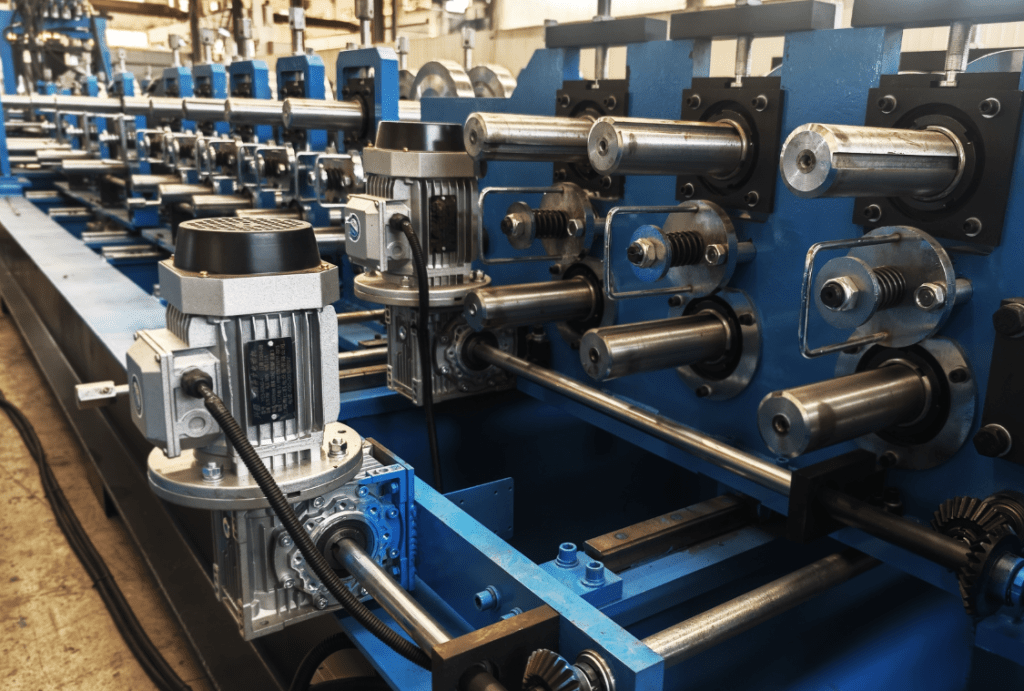

Unparalleled Design and Engineering

Our engineering team dedicated over two months to perfecting every detail of this machine. The Quick Change C/Z Purlin Roll Forming Machine is designed to meet the demanding requirements of modern construction. It offers a fully automated solution. The czu purlin roll forming machine seamlessly switches between the production of Cee & Zed purlins. This breakthrough equipment ensures a higher level of productivity and precision, reducing setup times and manual intervention to a minimum.

Key innovations include:

- Fully Automated Operation: With advanced computer-controlled systems, the machine automatically switches production modes based on the input dimensions displayed on the screen.

- Versatility in Purlin Production: The machine produces C-type purlins with a base width ranging from 80 to 300 mm (WEB) and a flange height (waist) between 40 and 80 mm. Additionally, it manufactures Z-type purlins with a base width of 100 to 300 mm and material thicknesses between 1.5 and 3 mm.

- Effortless Transition: While most changes are automated, the transition from C-type to Z-type production does require a manual 360° rotation of several roll stands, ensuring optimal alignment and performance.

This innovative approach has led to the creation of what we proudly refer to as the CZ Purlin Quick Change Roll Forming Machine, which has already garnered interest from manufacturers seeking to upgrade their production lines.

Cutting-Edge Automation and Efficiency

One of the most significant advantages of our new machine is its automation capability. The digital interface is user-friendly and intuitive, allowing operators to input the desired dimensions directly into the control system. This system automatically adjusts the roll forming process without the need for further human intervention, thereby reducing the chance of error and enhancing consistency across production batches.

Efficiency Highlights:

- Seamless Mode Switching: The integration of advanced sensors and computerized controls means that switching between C-type and Z-type production is not only fast but also highly accurate. Our machine is truly a cz purlin interchangeable roll forming machine, built to cater to diverse product specifications with minimal downtime.

- Reduced Setup Time: Traditional roll forming machines often require extensive manual adjustments. With our quick change mechanism, setup times are drastically reduced, allowing manufacturers to respond quickly to varying market demands.

- Increased Productivity: By automating most of the process, the cz interchangeable purlin roll forming machine ensures a continuous production flow. The pre-programmed settings allow for rapid switching between product types, making it ideal for high-volume production environments.

This C/Z Purlin Quick Change Roll Forming Machine is engineered to streamline operations and boost overall productivity, which is essential for businesses looking to stay competitive in a fast-paced market.

Precision Manufacturing for Superior Quality

Quality is at the forefront of our manufacturing philosophy. Every component of the Interchangeable C/Z Purlin Roll Forming Machine has been engineered to deliver exceptional performance and reliability. Our rigorous testing over the past 75 days has confirmed that the machine not only meets but exceeds industry standards.

Quality Assurance Features:

- Robust Construction: Built with high-grade materials, the machine is designed to withstand continuous operation in demanding industrial environments.

- Accurate Roll Forming: The precision of the roll forming process is maintained through computerized controls that ensure every purlin meets the exact dimensions specified by the operator.

- Consistent Output: With the ability to switch between different production modes effortlessly, the machine guarantees uniform quality across all purlin types. This is particularly important for projects that require a high degree of consistency in materials and dimensions.

Our commitment to quality ensures that the final product not only satisfies but also exceeds customer expectations, establishing a new industry benchmark for both performance and reliability.

Enhanced User Experience and Safety

Ease of use and safety are paramount in the design of our Interchangeable CZ Purlin Roll Forming Machine. The intuitive digital interface and automated controls are complemented by safety features that protect both the machine and its operators.

User-Centric Design:

- Intuitive PLC Control Panel: The user-friendly display allows operators to effortlessly input and adjust dimensions. This feature facilitates a smooth transition between different product settings.

- Safety Protocols: Multiple safety interlocks and sensors are integrated into the machine. They ensure that any potential issues are immediately detected. These measures address concerns quickly. This minimizes the risk of accidents and equipment damage during operation.

- Low Maintenance Requirements: Designed with efficiency in mind, the machine’s self-diagnostic features help in maintaining optimal performance with minimal downtime for maintenance.

These enhancements not only contribute to a better user experience but also ensure that the production process is safe, reliable, and efficient.

Meeting Industry Demands with Advanced Flexibility

The construction industry is rapidly evolving, and manufacturers are continually challenged to meet diverse and dynamic market needs. The C/Z Purlin Interchangeable Roll Forming Machine is a direct response to these demands. This machine provides a highly flexible production solution. It allows manufacturers to quickly adapt to different project requirements. They can do this without investing in separate equipment.

Market Advantages:

- Versatility in Production: The ability to produce both C-type and Z-type purlins with a single machine provides a competitive edge. This versatility is critical in reducing capital expenditures and streamlining operations.

- Cost Efficiency: The reduction in manual labor and decreased downtime translate into significant cost savings over time. This machine is designed to offer a rapid return on investment through increased throughput and reduced operating costs.

- Future-Proof Design: As market demands continue to shift, our machine is built to be adaptable. It includes upgrade paths and software updates. These ensure it remains at the cutting edge of technology.

Our machine is not just an investment in equipment; it’s an investment in the future of your production capabilities.

Why Choose Our Quick Change CZ Purlin Roll Forming Machine?

When you invest in our innovative machine, you are choosing a product that embodies precision, efficiency, and quality. Here are some compelling reasons why our machine stands out in the market:

- Innovative Automation: Experience the benefits of a fully automated system that reduces manual intervention and enhances production accuracy.

- Versatile Production: With the ability to produce a wide range of purlin dimensions, our machine offers unmatched flexibility.

- Proven Reliability: After 75 days of rigorous testing, our machine is ready for shipping and has demonstrated exceptional performance under demanding conditions.

- Cost-Effective Operation: Save on labor costs and improve overall efficiency with a machine designed to reduce setup times and minimize downtime.

- Advanced Safety Features: Operate with confidence knowing that our machine is equipped with comprehensive safety protocols.

Ready for Delivery – Transform Your Production Today

The completion of our pre-shipment test marks a significant milestone in our journey. We are excited to offer the Quick Change C/Z Purlin Roll Forming Machine to manufacturers looking for an edge in today’s competitive market. Its ability to quickly switch between production modes without sacrificing quality or efficiency makes it an indispensable tool for modern fabrication facilities.

As a leader in the industry, we are committed to continuous improvement and innovation. This machine is a testament to our dedication to excellence and our pursuit of technologies that redefine industry standards. We are confident that the Quick Change C/Z Purlin Roll Forming Machine will not only meet your current production needs but also provide a scalable solution for future growth.

Whether you are upgrading your current production line or expanding your manufacturing capabilities, our machine offers the precision, efficiency, and versatility required to succeed. Don’t miss the opportunity to be at the forefront of industry innovation – contact us today to learn more about how our machine can transform your purlin production process.

Thank you for your continued trust in our products and services. We look forward to supporting your journey toward greater efficiency and success.

Keywords: quick change c/z purlin roll forming machine, cz purlin quick change roll forming machine, cz purlin interchangeable roll forming machine

Discover the future of roll forming technology and elevate your production capabilities with our latest machine. Let’s build a stronger, more efficient tomorrow together.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.