Two-in-One Hat Channel Roll Forming Machine: Revolutionizing Metal Profiling

In the ever-evolving landscape of metal fabrication, technological advancements play a pivotal role in enhancing efficiency and precision. The two-in-one hat channel roll forming machine stands at the forefront of innovation, revolutionizing the way metal profiles are manufactured. This cutting-edge equipment seamlessly integrates versatility and functionality, offering a transformative solution for industries ranging from construction to automotive.

Table of Contents

Understanding Hat Channels:

Before delving into the intricacies of the two-in-one hat channel roll forming machine, it’s essential to grasp the significance of hat channels in metal construction. Hat channels are essential components in the framework of structures, providing structural support and facilitating the installation of various building materials, such as drywall and insulation. Hat channels, sometimes are called hat purlins, and also they are known as furring channels as well. The distinctive “hat” shape of these channels gives them enhanced strength and rigidity while minimizing material usage. The equipment that produces these hat purlins or hat channels or furring channels are called hat purlin roll forming machines.

Versatility Unleashed:

The two-in-one hat channel roll forming machine or hat purlin roll forming machine, or top furring channel roll forming machine takes versatility to new heights by accommodating the production of two different hat channel profiles on a single machine. This groundbreaking capability eliminates the need for separate machines for each profile, streamlining the manufacturing process and significantly reducing production costs. This adaptability makes the machine an invaluable asset for metal fabricators seeking enhanced efficiency and cost-effectiveness.

Key Features of two-in-one hat purlin roll forming machine:

Dual Profiling Capability:

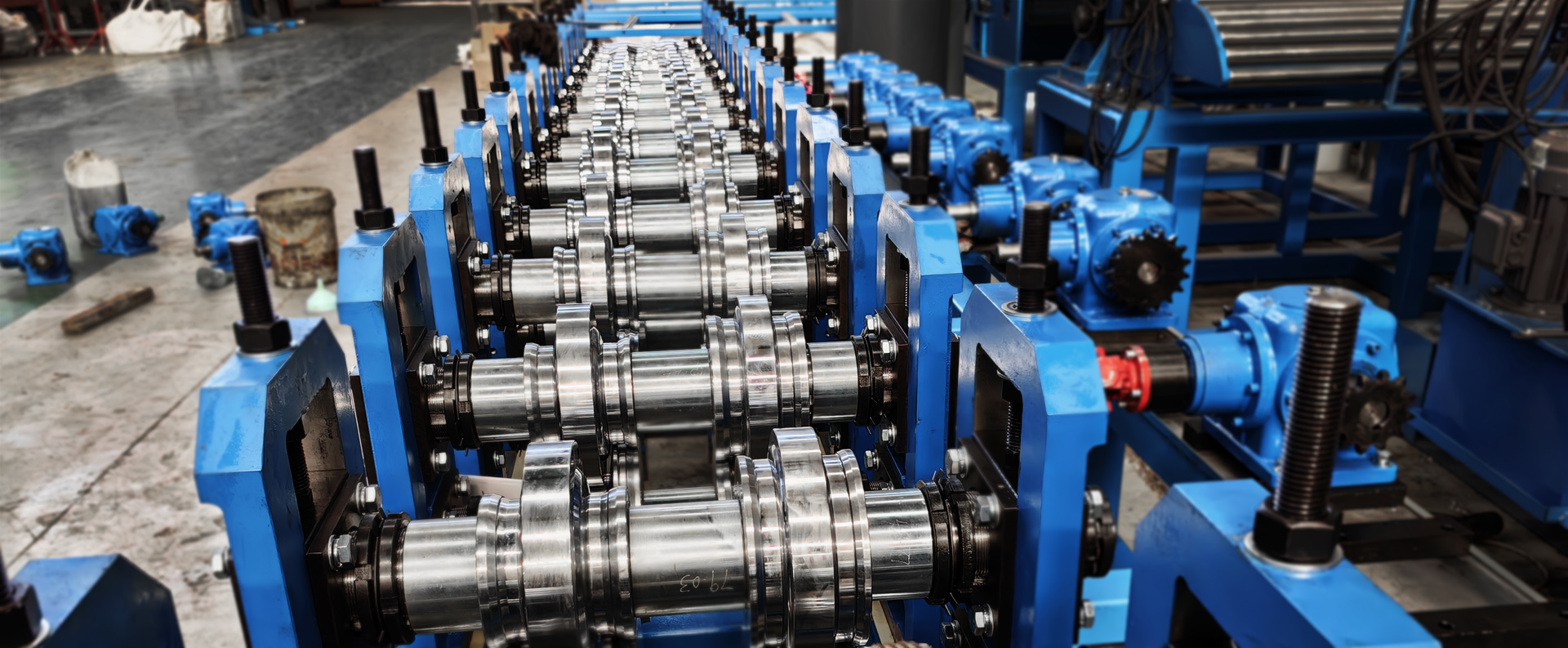

The standout feature of the two-in-one hat channel roll forming machine lies in its ability to produce two distinct hat channel profiles without the need for manual adjustments or machine reconfiguration. This is achieved through an intelligent and automated system that seamlessly transitions between profiles, allowing manufacturers to cater to diverse project requirements with minimal downtime.

Quick Changeover Mechanism:

To further enhance efficiency, the machine incorporates a quick changeover mechanism. This feature enables operators to switch between different hat channel profiles rapidly, minimizing production downtime and maximizing overall output. The intuitive design of this mechanism ensures that even operators with minimal training can perform changeovers with ease.

Precision Engineering:

Precision is paramount in metal fabrication, and the two-in-one hat channel roll forming machine excels in this regard. Advanced engineering and technology ensure that each profile is formed with consistent precision, meeting the highest industry standards. This level of accuracy not only enhances the structural integrity of the hat channels but also contributes to the overall quality of the final product.

Material Flexibility:

The machine’s design accommodates a wide range of materials, including steel, aluminum, and other metals commonly used in construction. This material flexibility empowers manufacturers to cater to diverse project requirements, opening up new possibilities for creative design and engineering solutions.

Benefits of the Two-in-One Hat Channel Roll Forming Machine:

Cost Efficiency:

By consolidating two profiling processes into a single machine, manufacturers significantly reduce equipment investment and maintenance costs. The two-in-one hat channel roll forming machine optimizes resource utilization, making it an economically sound choice for businesses aiming to enhance their bottom line.

Increased Productivity:

The quick changeover mechanism and automated profiling capabilities translate into increased productivity. The machine minimizes downtime associated with profile changes, allowing manufacturers to meet tight production schedules and fulfill customer orders promptly. This heightened efficiency directly contributes to improved overall output.

Customization Opportunities:

The flexibility of the two-in-one hat channel roll forming machine extends beyond efficiency gains. Manufacturers can now offer greater customization options to their clients by effortlessly switching between different hat channel profiles. This adaptability caters to the evolving demands of the construction and manufacturing industries, where unique and tailored solutions are increasingly valued.

Streamlined Workflow:

Integrating a two-in-one hat channel roll forming machine into the production line streamlines the entire workflow. With reduced machine changeovers and optimized material handling, manufacturers can achieve a seamless and efficient production process, resulting in a more organized and cost-effective manufacturing environment.

Top Furring Channel Roll Forming Machine Professional Manufacturer

MTC is specialized in customising roll forming equipment and top furring channel roll forming machine is one of our regular products. The two-in-one top furring channel roll forming machine marks a significant leap forward in the field of metal profiling. Its dual profiling capability, quick changeover mechanism, precision engineering, and material flexibility make it a game-changer for metal fabricators seeking to enhance efficiency and stay competitive in a dynamic market. As industries continue to demand cost-effective and versatile solutions, the two-in-one hat channel roll forming machine emerges as a technological marvel, reshaping the landscape of metal fabrication for a more productive and innovative future.