G Channel Roll Forming Machine | Heavy-duty Solar Mounting Frames Manufacturing

Unlocking the Power Behind Solar Mounting with the G Channel Roll Forming Machine

As the solar industry continues its rapid global expansion, the demand for durable, precise, and efficient mounting structures is growing exponentially. At the heart of these structures lies the solar strut channel, also widely known as the G channel. To meet this industrial demand, we proudly introduce our G Channel Roll Forming Machine – a high-performance solution designed for modern solar mounting applications.

Let’s look into what makes the G channel essential, how it compares to other common profiles like C channels and U channels (More details at C/U/G Solar Channels vs Unistrut Solar Channels: Why There Is No Standard Solar Mounting Frame), and how our roll forming machine offers unmatched advantages in solar support frame production.

Table of Contents

What Is a G Channel? Why Is It Crucial in Solar Applications?

The G channel, also referred to as the solar strut channel, is a steel profile specially used for solar mounting systems. Its unique design provides a perfect balance of structural rigidity, lightweight performance, and ease of assembly, making it ideal for supporting photovoltaic panels in ground-mounted and rooftop installations.

G channels are often pre-punched with slots or holes to accommodate various solar brackets, fasteners, and components. This standardized yet customizable approach reduces labor time and simplifies on-site installation – a huge benefit for solar project developers and installers.

C Channel vs. U Channel vs. G Channel: Understanding the Differences

Before choosing the right roll forming equipment, it’s essential to distinguish between the common unistrut channel solar mounting frames: C channels, U channels, and G channels.

| Feature | C Channel | U Channel | G Channel |

|---|---|---|---|

| Shape | Has inward-facing lips forming a “C” shape | Straight U shape with open ends | Similar to C channel but optimized for solar mounting |

| Rigidity | High | Moderate | Very high with better design for load distribution |

| Application | Framing, support, industrial use | Lightweight applications | Solar mounting, cable support, structural support |

| Punching | Typically custom or done post-rolling | Minimal | Often includes pre-punched holes or slots |

| Compatibility | Moderate | Limited | Designed for modular solar system components |

| Equipment | C Strut Channel Roll Forming Machine | Solar strut channel roll forming machine | G type stut channel Machine |

The G channel stands out due to its enhanced modularity and compatibility with solar installation systems. It combines the strength of C channels with optimized punching and geometry specific to solar projects.

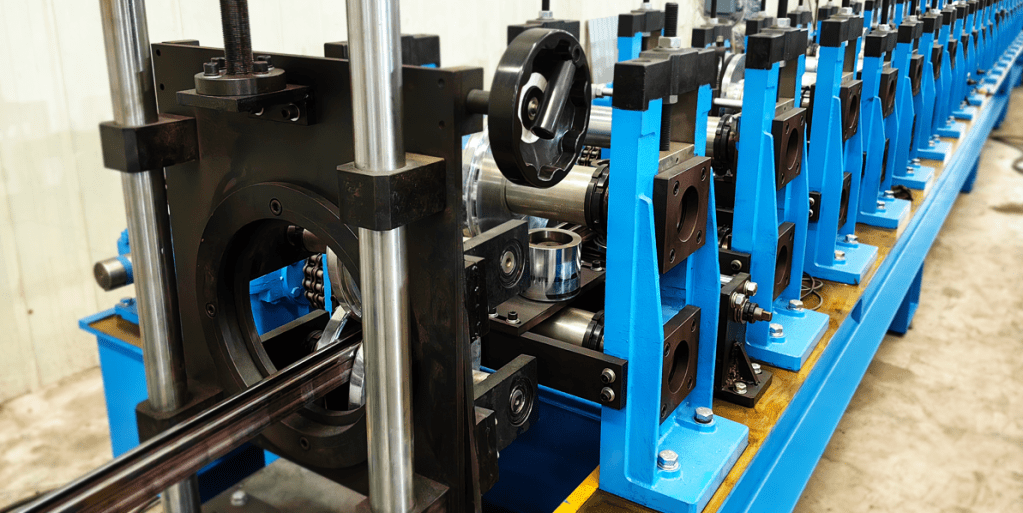

Introducing Our G Channel Roll Forming Machine – Your Solar Strut Channel Production Powerhouse

Our G Channel Roll Forming Machine, also known as the “G” type solar strut channel machine, is specially developed to meet the rigorous demands of solar mounting system manufacturers.

Here are the top features and benefits of this advanced system:

1. Independent Cast Iron Stands – Superior Durability & Stability

Unlike traditional welded base frames, our cast iron stand roll forming machine is engineered with independent cast iron stands, offering robust support and vibration resistance during high-speed operation. These stands ensure long-term alignment precision and reduce wear and tear on rollers and shafts.

- Advantage: Perfect roll positioning for consistent product quality.

- Benefit: Longer machine life, reduced maintenance.

2. Gearbox Transmission System – Power That Lasts

Our roll forming system utilizes a gearbox-driven transmission, replacing traditional chain drives. This upgrade ensures smooth torque transfer, higher speed, and long-term mechanical efficiency.

- Advantage: Minimizes transmission backlash and power loss.

- Benefit: Delivers consistent forming accuracy and low noise.

3. Hydraulic Tracking Punch Unit – Precision on the Move

One of the standout features of our machine is the hydraulic tracking punching unit. Unlike fixed punching stations, this dynamic punching system moves along with the strip as it feeds through the line.

- Advantage: Allows high-speed punching without stopping the line.

- Benefit: Greatly increases productivity and ensures hole accuracy without distortion.

4. Fly-Saw Cutoff Unit – Cut Without Compromise

To ensure high-speed and burr-free cutting, our G channel roll forming machine is equipped with a fly-saw cutting system. This servo-driven unit synchronizes with the formed profile, cutting the channel without interrupting the roll forming process.

- Advantage: Continuous production and clean, square cuts.

- Benefit: Higher throughput and less material waste.

5. Roll Design for G Channel – Customized to Your Profile

We offer fully customized roller sets based on your G channel specifications. Our engineering team uses CAD/CAM simulation and finite element analysis to design precise forming passes that minimize stress, cracking, and springback in the metal.

- Materials: Typically designed for galvanized steel, stainless steel, or aluminum.

- Thickness range: 1.5mm – 2.5mm or as per customer requirement.

Technical Specifications at a Glance:

| Feature | Specification |

|---|---|

| Material | Galvanized steel / Mild steel / Stainless steel |

| Thickness | 1.5–2.5 mm |

| Max Line Speed | Up to 15–20 m/min (with punching & cutting) |

| Transmission | Gearbox |

| Frame Structure | Cast Iron Stands |

| Cutting Type | Fly-Saw Cutting |

| Punching | Hydraulic Tracking Punch |

| Control System | PLC Automatic Control with Touch Screen |

| Length Tolerance | ±0.5 mm |

Why Choose Our Unistrut Channel Roll Former?

- ✅ High Precision: Dimensional consistency for perfect profile matching.

- ✅ High Efficiency: Continuous production with punching and cutting on the fly.

- ✅ Low Downtime: Heavy-duty components built for 24/7 production.

- ✅ Customizable: Adjust roller design, punching patterns, and cutting lengths to your needs.

- ✅ Turnkey Support: We offer installation, training, and lifelong technical support.

Applications of the G Channel

- ✅ Solar panel mounting structures

- ✅ Cable tray systems

- ✅ Mechanical and electrical support frameworks

- ✅ Modular shelving and construction framing

- ✅ Industrial racking systems

The versatility of G channels makes them essential for a wide range of industries beyond just unistrut channels for solar energy.

Final Thoughts: Power Your Solar Projects with Our Precision Solar Mounting Roll Forming Line

As solar energy continues to power the future, infrastructure that supports clean energy must be just as advanced. Our Solar bracket profile forming machine represents the next generation of manufacturing technology, offering high-speed performance, unmatched precision, and robust reliability.

Whether you’re building solar panel mounts, racking systems, or general industrial strut profiles, this solar bracket mounting roll forming machine is the key to scaling your production efficiently and affordably.

Contact us today for a free consultation, layout design, and sample profile analysis. Let’s build the future of solar—one G channel at a time.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.

[…] 2. G-Type Solar Channels […]