Applications: Hat Purlins, Furring Channels, Roof and Ceiling Battens

Explore the common questions and answers about Light Gauge Steel Frame Machines

A: A light gauge steel frame machine is a fully automated roll forming system used to produce structural profiles such as C studs, U tracks, hat channels, roof and ceiling battens, and furring channels. These machines shape galvanized steel coils into framing components for wall, ceiling, and roof structures used in modern residential and commercial construction.

A: A c stud roll forming machine forms vertical wall studs, while a u track roll forming machine produces horizontal floor and ceiling tracks. Both are essential components of drywall framing systems, and many manufacturers use a combined stud and track roll forming machine to produce both profiles efficiently.

A: A multi-profile roll forming machine allows one line to produce different profile types—such as C, U, Hat, or Omega sections—on a single shaft with multiple roller sets. It reduces the need for separate machines and enables quick changeovers between profile types, saving space and improving production efficiency.

A: These machines typically process galvanized steel, stainless steel, or aluminum sheets with thicknesses between 0.3 mm and 1.2 mm. Material choice depends on the structural strength, corrosion resistance, and finishing requirements of the framing project.

A: Depending on its configuration, the machine can manufacture C and U studs, corner beads, furring channels, Omega profiles, and hat purlins. Some systems, such as the multi-profile roll forming machine, can produce several shapes on one line by adjusting roller positions or feeding setups.

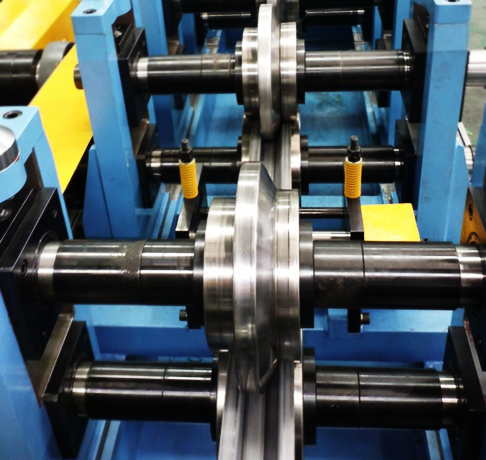

A: The hat-shaped series roll forming machine, like the furring channel roll forming machine uses multiple forming rollers to shape flat steel strips into hat channels or roof battens. These profiles are commonly used for ceilings, roof structures, and wall furring systems, offering strong yet lightweight framing support.

A: Yes. The angle and corner bead roll forming machine can be equipped with a punching or perforation system to create vent holes or textured surfaces. These holes improve plaster adhesion and enhance the finishing quality of drywall edges and corners.

A: When selecting a light gauge steel framing machine, consider the required profile types, production speed, material thickness, and automation level. For example, a c stud and u track roll forming line suits drywall systems, while a hat purlin roll forming machine fits ceiling and roof structures.