Troubleshooting Guide: Roller Gap Adjustment of Metal Roll Forming Machines

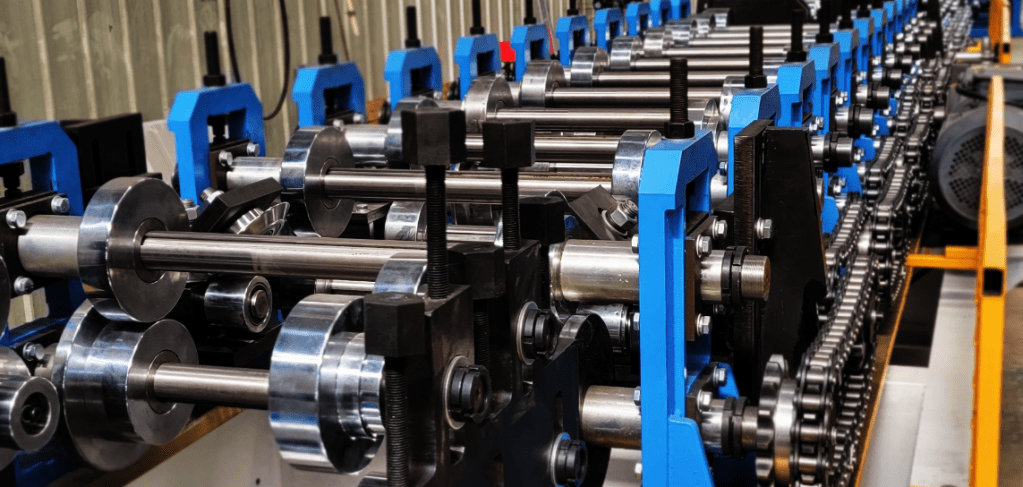

Adjusting roller gaps accurately is a critical task in operating metal roll forming machines. If the roller gap is not set correctly according to the material thickness, it can lead to a host of problems—poor profile quality, premature roller wear, excessive machine vibration, and even material jamming or damage. Whether you operate a cold roll forming machine, a cold roll former, or an advanced metal roll forming equipment system, knowing how to troubleshoot and adjust roller gaps (roll forming machine roller gap adjustment) is essential for smooth and consistent operation.

This guide provides a detailed and practical approach to adjusting roller gaps for different material thicknesses. It will help machine operators, maintenance personnel, and production managers maximize the efficiency and longevity of their roll forming machine equipment.

Table of Contents

Why Roll Forming Machine Roller Gap Adjustment Matters

Roller gap refers to the distance between the upper and lower rollers at each station of a roll forming line. This gap determines the amount of pressure applied to the sheet metal as it passes through the metal roll forming equipment.

If the gap is too tight, it will overcompress the material, causing excessive wear on tooling, oil canning, edge cracking, or buckling. If it’s too loose, the forming quality will suffer, resulting in dimensional inaccuracies, waviness, or loss of profile integrity.

Therefore, adjusting the roller gap based on the actual thickness of the material is not just recommended—it is mandatory for producing high-quality products consistently on any cold roll forming machine.

Common Symptoms of Incorrect Roller Gaps

Operators often encounter specific problems that point directly to incorrect roller gaps. These include:

- Edge waviness: Often due to excessive roller pressure or uneven gap settings.

- Twisting or bowing of profile: A result of asymmetric pressure distribution.

- Scratches or surface marks: Indicates rollers are too tight or not aligned.

- Thickness variation across profile: Due to inconsistent gap settings between stands.

- Unusual noise or vibration: Can signal binding or metal stress in the system.

Identifying these symptoms early allows for timely roller gap adjustments, avoiding machine downtime and costly rework.

Tools and Equipment Required

Before beginning the adjustment, gather the following tools:

- Feeler gauges (for precise measurement)

- Digital or manual calipers

- Adjustment wrenches or spanners

- Torque wrench (optional but recommended)

- Thickness gauge (to verify material thickness)

Note: Always wear protective gear and follow safety protocols before performing any maintenance or adjustment on a cold roll former or any roll forming machine equipment, like unistrut channel roll forming machine.

Methods for Adjusting the Gaps

1. Verify the Material Thickness

Start by measuring the actual thickness of your incoming metal coil using a calibrated thickness gauge or micrometer. Metal suppliers often provide nominal thickness, which may slightly differ from the actual value. Adjustments must be based on real thickness, not theoretical values.

2. Access the Roller Stations

Shut off the machine and lock it out following proper safety procedures. Open the protective covers to access the roller stations. Most metal roll forming machines, like unistrut channel roll forming machine, will have upper roller blocks that can be adjusted vertically using bolts or cams.

3. Set Initial Gap Based on Thickness

A common rule of thumb is to set the roller gap equal to the material thickness plus a small clearance (typically 0.02–0.05 mm depending on the machine and material type). For instance, for 1.0 mm thick steel:

- Initial roller gap = 1.0 mm + 0.03 mm = 1.03 mm

Use feeler gauges to set this gap at both ends of the roller, ensuring it is even. Some customized roll forming machines may have micrometer adjustment knobs or digital controls for precision.

4. Align Left and Right Side Gaps

It’s essential that the roller gap is uniform across the profile width. Use feeler gauges or calipers to verify that both the left and right sides of the rollers have identical gaps. Misalignment will cause profile twisting or asymmetric stress.

If a discrepancy is found, adjust the side with the greater gap until both sides match.

5. Perform a Trial Run

Restart the metal roll forming equipment at a slow speed and run a short strip of the material through the forming stations. Stop the machine and inspect the output:

- Are the edges smooth?

- Is the profile shape consistent?

- Are there marks or bends?

If issues persist, fine-tune the roller gap at specific stations depending on the profile geometry and material behavior.

Tips for Adjusting Roll Gaps by Material Type

Different materials react differently under pressure. Here are some practical adjustment tips for various materials:

Mild Steel

- Requires tighter gaps due to its stiffness.

- Start with +0.03 mm clearance.

Galvanized Steel

- Slightly softer; coating may get scratched if the gap is too tight.

- Use +0.04–0.05 mm clearance.

Aluminum

- Very soft and ductile; scratches easily.

- Set a looser gap and ensure rollers are extremely clean.

Stainless Steel

- Harder and springier; needs slightly more forming pressure.

- Use tighter gaps but avoid excessive compression that causes edge cracking.

Always test before full production. Each cold roll former and profile type may have unique behavior, and historical data from previous production runs is valuable for setting baseline parameters.

Preventive Maintenance and Best Practices

Adjusting roller gaps is not a one-time task. Regular maintenance ensures your roll forming machine equipment continues to deliver consistent quality. Here are some best practices:

- Check roller gaps weekly or after every major production run.

- Clean the rollers regularly to avoid debris affecting the gap.

- Document all adjustments—material thickness, roller gap, forming speed—for future reference.

- Train all operators on the principles of gap setting and the consequences of incorrect adjustment.

Advanced Options: Automatic Gap Adjustment Systems

Modern metal roll forming machines may come equipped with CNC or servo-controlled roller gap adjustment systems. These can store material profiles and automatically adjust roller gaps based on pre-set recipes. This not only saves time but also reduces human error and increases repeatability.

However, even with automation, operators must verify calibration and validate gap settings occasionally, especially when switching between different material lots or thicknesses.

Fine-tuning roller gaps might seem like a small detail in the overall operation of a metal roll forming machine, for example for IND facade panel, but in practice, it makes all the difference. From improving the consistency of your output to reducing unnecessary wear on your tooling, precise gap adjustments are what separate efficient production lines from problematic ones.

Operators who build a habit of checking and adjusting the roller gaps regularly—based on actual material thickness and forming feedback—will experience fewer profile defects, smoother machine operation, and longer equipment life. Whether you’re working with galvanized steel, aluminum, or stainless steel, tailoring your settings to match the characteristics of each batch ensures your cold roll forming machine keeps performing at its best.

If you’re aiming for precision, efficiency, and low reject rates, then this should become a core part of your roll forming machine equipment workflow. A small adjustment today can prevent a major problem tomorrow.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.