IDT Metal sheet roll forming machines minimize your building costs!

Metal sheet roll forming machines have been designed to produce roof panels with customized shapes, like IBR sheets, standing seam sheets and IDT roofing sheets. IDT roofing roll forming machine is the main character we are discussion today.

The pre-painted & galvanized zinc steel or aluminum IDT roof panels which made by this roll former have neat external appearance, even ripples, high utilization and strong strength. Besides, this roof sheets corrugation machine can cooperate with its curving machine to fit your roofing design.

Table of Contents

Explore IDT Roofing Sheets

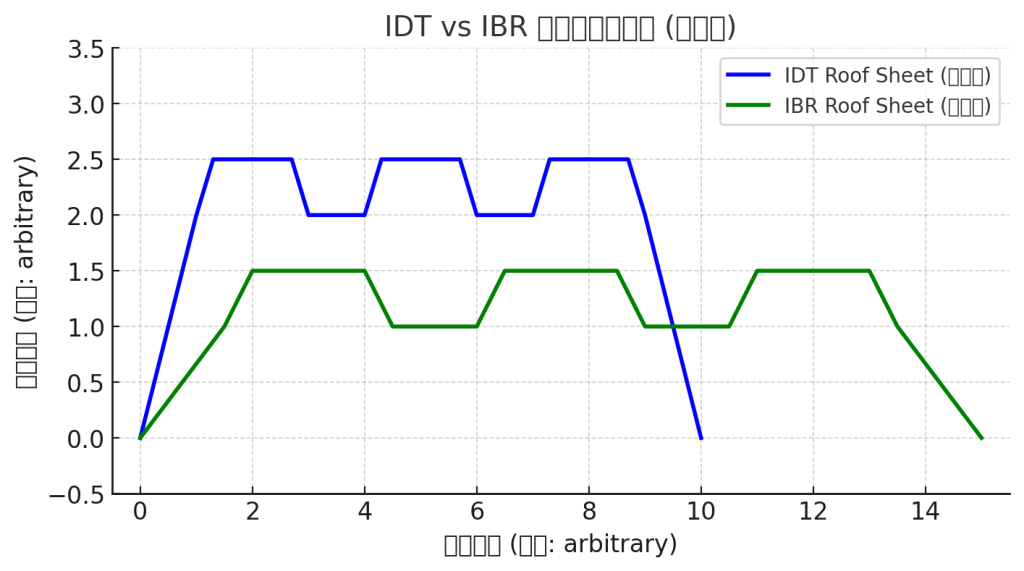

The IDT (Inverted Deck Trapezoidal) roofing sheet offers an innovative solution for modern building needs, characterized by its higher and narrower flutes that create deeper drainage valleys. This superior design sets it apart from other roofing options such as IBR (Inverted Box Rib) sheets in South Africa (see IBR sheet roll forming machine)and Klip-Lok or Concealed Fix Roof Sheets in Australia and China. In addition to its striking aesthetic appeal, the unique fluted form of the IDT sheet provides a tight interlocking mechanism, effectively preventing any potential leakages.

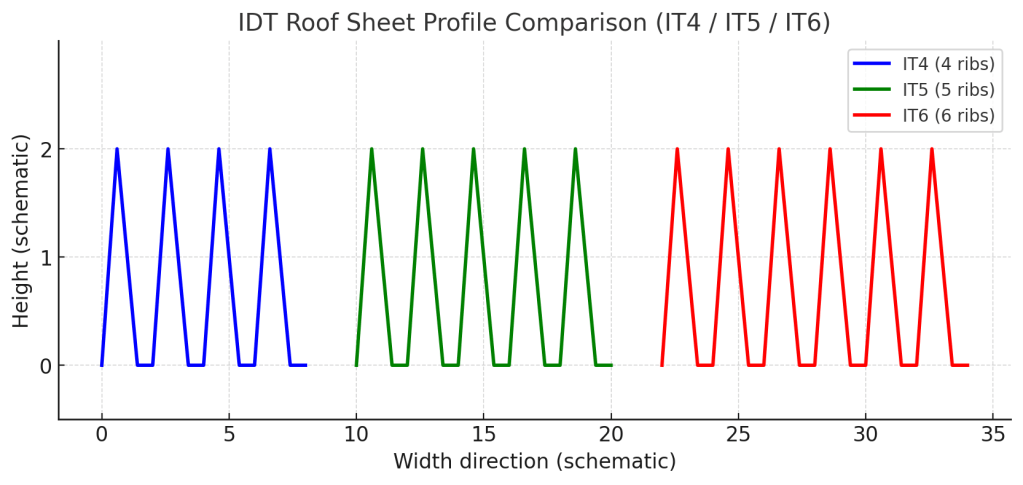

The IDT profile can be customized based on the number of ribs or waves. Each variation, such as IT4, IT5, and IT6, allows for specific aesthetic and functional demands. The ability to adjust design features enables builders to select the perfect type of IDT roofing sheet that aligns with their structural and architectural goals. Let’s delve deeper into what makes IDT roofing sheets a preferred choice and explore the corresponding roll forming machines used in their production.

| Model | Effective Cover Width (mm) | Coil Input Width (mm) | Rib Height (mm) | Main Ribs | Thickness (mm) | Typical Application |

|---|---|---|---|---|---|---|

| IT4 | 800–820 | 925–940 | 25–30 | 4 | 0.25 – 0.40 | Wall cladding, light roofing |

| IT5 | 910–930 | 1060–1080 | 28–32 | 5 | 0.25 – 0.45 | Most popular, residential & factory roofing |

| IT6 | 1000–1020 | 1160–1180 | 28–35 | 6 | 0.25 – 0.50 | Large-span roofing, warehouses, industrial buildings |

Advantages of IDT Roofing Sheets

- Aesthetic Versatility: The sleek design of IDT roofing sheets enhances the visual appeal of any structure. Their clean lines and modern profile fit seamlessly with various architectural styles, making them an ideal choice for builders and homeowners aiming for elegance.

- Superior Drainage: The deep flutes of IDT sheets are engineered to facilitate efficient water drainage, reducing the risks of water ponding that can lead to leaks and water damage, thereby enhancing the roof’s durability.

- Tight Interlocking Mechanism: The fluted design ensures that each panel locks onto the next, forming a secure barrier against moisture intrusion. This quality is critical in regions with heavy rainfall or adverse weather conditions.

- Durability and Longevity: Made from robust materials like galvanized steel and aluminum, IDT roofing sheets resist corrosion, thereby prolonging their lifespan and reducing maintenance needs.

- Eco-Friendly: The high recyclability of IDT roofing sheets contributes to sustainable building practices, providing an eco-friendly roofing option for environmentally conscious consumers.

Broader Applications of IDT Roofing Sheets

IDT roofing sheets are not just limited to single-family homes—they are widely utilized in various sectors, including:

- Commercial Buildings: Their robust nature makes them an excellent choice for warehouses and retail spaces, providing unobtrusive yet effective shelter.

- Industrial Facilities: Often employed in factories, these sheets offer safe and durable coverings that can withstand challenging operational environments.

- Residential Properties: Increasingly popular amongst homeowners, IDT sheets deliver quality roofing solutions that enhance property value while being aesthetically pleasing.

Global Usage and Trends

Countries like India, China, Japan, the USA, the UK, Austria, Australia, and the UAE have embraced IDT roofing sheets and roll forming machines extensively. The global demand continues to rise as construction practices emphasize energy efficiency, durability, and design flexibility.

Overview of IDT Roofing Sheet Roll Forming Machines

Metal Roofing sheet roll forming machines have been designed to produce roof panels with customized shapes, like IBR sheets, standing seam sheets and IDT roofing sheets which are the best for customers who desire aesthetic appeal.

The production of IDT roofing sheets relies on specialized automatic roll forming machines that are adept at creating these distinct profiles. While the molds and shapes may vary based on specific project requirements, the fundamental configuration and processing methods of IDT roofing sheet roll forming machines remain consistent.

It is also available to customize separate machines for different profiles, like IT4 roof panel roll forming machines, IT5 sheet roll forming machines and IT6 roof panel machines etc.These specialized mills are prevalent in the light gauge framing industry where metal studs and tracks of standardized profiles and thicknesses are also used. IDT roof panel roll forming machine is, among the manufacturing processes, one of the simplest. It typically begins with a large coil of sheet metal.

Components of IDT Roof Sheet Roll Forming Machines

IDT roofing Roll Forming Machine composed of decoiler, feedingi guide, roll forming and cutter solution etc. Typically, these machines comprise essential components including:

- Decoiler: Provides a controlled feed of metal coils into the machine.

- Sheet Guiding Equipment: Ensures precise alignment of metal sheets throughout the forming process.

- Roll Forming System: The core component that shapes the metal into the desired IDT profile.

- Cutter: This unit allows for accurate cutting of sheets to specified lengths.

- Support Table: Offers stability and proper handling of the finished sheets.

- Hydraulic System: Powers various functions within the machine.

- Control System: Integrates technology for user-friendly operation and machine monitoring.

Technical Parameters of IDT Roof Sheet Machine

| Technical Parameter | Specification |

|---|---|

| Material Thickness | 0.25 mm to 0.5 mm |

| Sheet Width | 925-1250mm |

| Production Speed | 0-12m/min |

| Weight of Machine | Approx. 6 TONS |

| Power Supply | 380V/50Hz |

| Roller Stations | 18 stations |

| Cutter Type | Hydraulic |

| Automation Level | Fully automatic with PLC control |

| Control System | Touch screen for operation and monitoring |

Why is an IDT roofing sheet forming machine necessary?

- IDT roofing sheet roll forming machine can handle any project size.

- Roll forming also makes it easier to produce longer lengths than are typically available on a stamping press.

- Metal roofing can consist of a high percentage of recycled material and is 100% recyclable.

- IDT roofing sheet roll forming can provide much closer tolerances than other metal processes.

- Proficient in complex and custom jobs.

- On a larger scale, the IDT roofing sheet metal can reduces the heat island effect of cities when compared to asphalt. Coupled with its better insulating abilities

These are some other metal sheet roll forming machine that cover different advantages and reasons on using IDT roofing sheer roll forming machine.

Frequently Asked Questions (FAQ)

1. What is an IDT sheet roll forming machine?

An IDT (Inverted Deck Trapezoidal) sheet roll forming machine is a specialized equipment used to produce roofing sheets with distinctive trapezoidal profiles. It utilizes a series of rollers to shape metal coils into the desired IDT design, which enhances both aesthetic appeal and functionality.

2. What materials can be used with IDT sheet roll forming machines?

IDT sheet roll forming machines can handle various materials, including galvanized steel, aluminum, and copper. These materials are known for their durability, corrosion resistance, and suitability for different architectural applications.

3. How does the roll forming process work for IDT sheets?

The roll forming process begins with feeding a metal coil into the machine, where it is guided through several rollers that progressively shape it into the IDT profile. After shaping, the sheets are cut to specified lengths, ready for installation.

4. What are the advantages of using IDT roofing sheets?

IDT roofing sheets offer several benefits, including superior aesthetic versatility, excellent drainage capabilities, tight interlocking mechanisms for leak prevention, durability, and eco-friendliness due to their high recyclability.

5. Can the IDT sheet roll forming machine produce different sheet sizes?

Yes, the machine can produce sheets of varying sizes and thicknesses. Adjustments can be made to the roller distances to accommodate different project specifications and to enable rapid changeovers between different sheet profiles.

6. What applications are suitable for IDT roofing sheets?

IDT roofing sheets are widely used in commercial buildings, industrial facilities, and residential properties. Their robust design makes them suitable for a variety of environments, offering effective shelter while enhancing aesthetic appeal.

[…] have their names by the products they make. Some machines we may know or hear about are like IDT sheet roll forming machine, trapezoidal sheet roll forming machine, and PBR panel or R-panel roll former […]