IBR Roofing Sheet Roll Forming Machine: Precision, Efficiency, and Durability

In the construction and roofing industry, the demand for efficient and cost-effective solutions has led to the development of advanced machinery and technologies. One such innovation is the IBR roofing sheet roll forming machine. This article delves into the significance of IBR roofing sheet roll forming machines, highlighting their benefits, applications, and contributions to modern construction practices.

Table of Contents

Understanding IBR Roofing Sheet Roll Forming Machine

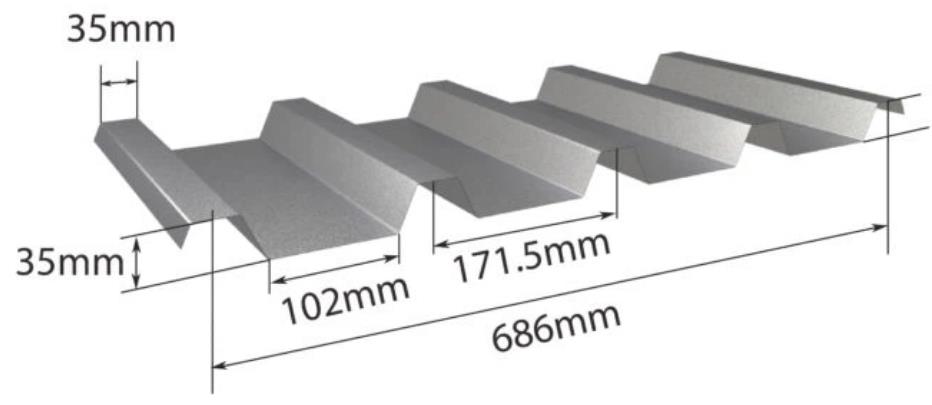

The acronym “IBR” stands for “Inverted Box Rib,” a term that refers to a popular roofing profile characterized by its distinctive trapezoidal shape with alternating flutes and ridges. The IBR sheet roll forming machine is a specialized piece of equipment designed to transform flat metal sheets into IBR roof panels with precision and efficiency. This process involves passing the metal sheets through a series of rollers and forming stations, where they are gradually shaped into the desired profile.

Benefits of IBR Roofing Sheet Roll Forming Machine

Consistency and Precision:

IBR roofing sheet roll forming machines are engineered for high precision. They ensure consistent dimensions and shapes for each panel produced, leading to accurate installation and a visually pleasing result.

Speed and Efficiency:

These machines can produce IBR roof panels at a rapid pace, meeting the demands of large construction projects. The automation of the process reduces labor requirements and accelerates project timelines.

Customization:

Modern IBR roofing sheet roll forming machines are adjustable, allowing for easy customization of panel dimensions, lengths, and other specifications according to project requirements.

Material Savings:

The precision of the roll forming process minimizes material wastage, making it a cost-effective solution in the long run. Additionally, the ability to work with various metals including steel, aluminum, and copper further enhances material efficiency.

Durability and Longevity:

IBR roof panels produced by these machines are known for their durability and weather resistance. The precise forming process ensures that panels fit snugly together, reducing the likelihood of leaks and enhancing the overall lifespan of the roof.

Ease of Installation:

The uniformity of panels and their interlocking design streamline the installation process, making it easier for contractors to assemble the roof efficiently

Contributions to Modern Construction Practices

The versatility of IBR roofing profiles contributes to a wide range of applications across various industries:

Residential Construction: IBR roofs are commonly used in residential buildings due to their aesthetic appeal, durability, and ease of maintenance. The roll forming machine’s ability to produce custom lengths ensures a seamless fit for any residential project.

Commercial and Industrial Structures: Large-scale commercial and industrial complexes often opt for IBR roofing due to its strength and ability to cover vast areas with minimal structural support. The roll formed panels are well-suited for warehouses, factories, and other industrial facilities.

Agricultural Buildings: The efficiency of IBR roofing sheet roll forming machines is particularly valuable in agricultural settings where large barns, sheds, and storage facilities require quick and durable roofing solutions.

Infrastructure Projects: IBR roofing is also employed in infrastructure projects such as airports, bus terminals, and train stations. The ability to cover expansive areas efficiently makes IBR roofing a practical choice for such applications.

Renewable Energy Structures: The durability of IBR roofing panels makes them suitable for solar panel installations, supporting the growth of renewable energy projects.

Residential Construction: IBR roofs are commonly used in residential buildings due to their aesthetic appeal, durability, and ease of maintenance. The roll forming machine’s ability to produce custom lengths ensures a seamless fit for any residential project.

Commercial and Industrial Structures: Large-scale commercial and industrial complexes often opt for IBR roofing due to its strength and ability to cover vast areas with minimal structural support. The roll formed panels are well-suited for warehouses, factories, and other industrial facilities.

Agricultural Buildings: The efficiency of IBR roofing sheet roll forming machines is particularly valuable in agricultural settings where large barns, sheds, and storage facilities require quick and durable roofing solutions.

Infrastructure Projects: IBR roofing is also employed in infrastructure projects such as airports, bus terminals, and train stations. The ability to cover expansive areas efficiently makes IBR roofing a practical choice for such applications.

Renewable Energy Structures: The durability of IBR roofing panels makes them suitable for solar panel installations, supporting the growth of renewable energy projects.

Applications of IBR Roof Sheet Roll Forming Machine

The IBR roofing sheet roll forming machine has revolutionized modern construction practices in several ways:

Specifications of IBR Roofing Sheet Making Machine

The IBR roofing sheet roll forming machine stands as a testament to the innovative strides made in the construction industry. Its ability to efficiently produce high-quality, durable, and customizable IBR roof panels has transformed the way roofs are designed, installed, and maintained. As construction practices continue to evolve, the roll forming machine’s contributions will undoubtedly play a crucial role in shaping the future of roofing solutions.

IBR Roofing Sheet Roll Forming Machine: Precision, Efficiency, and Durability was last modified: August 24th, 2023 by

Categories:

What is the price of such line?

Can you please send us a email via info@mtc-china.com for your kind inquiry?