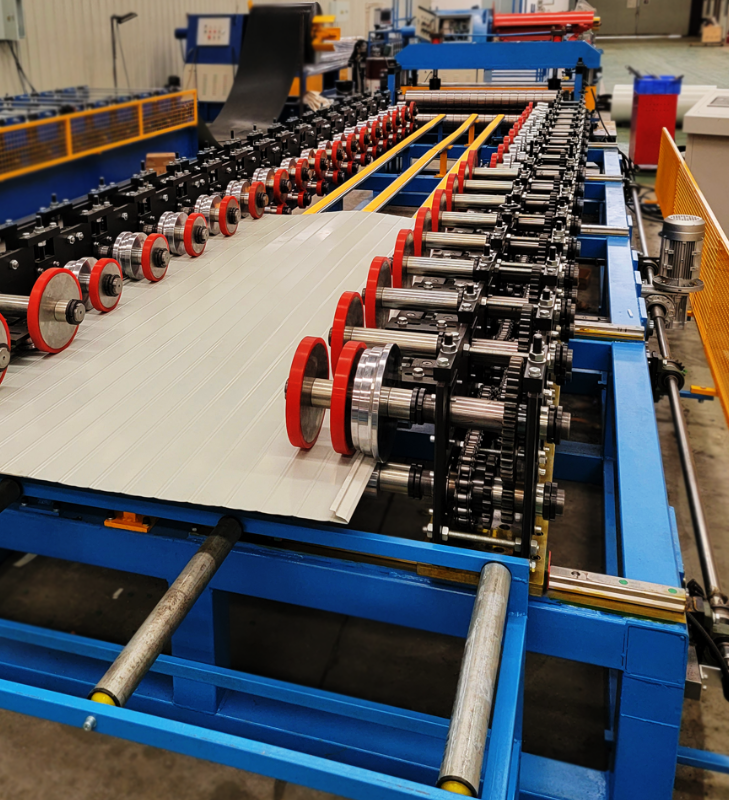

Completion of a Width Adjustable Roll Forming Machine for PU Sandwich Panel Lines

We are proud to announce the successful completion of our latest engineering achievement—an advanced width adjustable roll forming machine specially designed for use in continuous PU sandwich panel production lines. As a leading roll forming machine manufacturer and trusted Chinese roll forming machine factory, we are committed to delivering cutting-edge equipment that enhances efficiency, adaptability, and precision for the global construction and building materials industry.

This newly completed machine reflects our dedication to developing automatic roll forming machines that align with industry demands and evolving production methods.

Table of Contents

Designed for Continuous PU Sandwich Panel Production Lines

Unlike equipment built for batch-style or discontinuous operations, this roll forming machine is engineered specifically to serve continuous PU sandwich panel lines. These lines are preferred by manufacturers looking for high-speed, high-accuracy production of insulated wall and roof panels, particularly for modern, energy-efficient buildings.

The roll former is responsible for shaping the top and bottom metal sheets—usually pre-painted galvanized steel or aluminum—which are later injected with polyurethane (PU) foam in a continuous process. This approach ensures consistent panel quality, better adhesion, and greatly enhanced production efficiency compared to traditional methods.

Material Compatibility and Technical Specs

This width adjustable roofing panel machine accommodates coil widths ranging from 1000 mm to 1250 mm, making it suitable for a variety of profile sizes and custom specifications. It can process steel sheets with thicknesses between 0.3 mm and 0.6 mm, which are commonly used for PU sandwich panel applications.

Thanks to its solid mechanical construction and carefully aligned roll stations, this customized roll forming machine can handle different materials—including pre-painted galvanized steel (PPGI), galvalume (AZ100), and aluminum—without compromising profile integrity or forming accuracy.

Advanced Width Adjustment for Flexible Panel Production

One of the most innovative features of this machine is its adjustable width design. In traditional roll forming setups, changing the profile width typically requires changing the entire tooling set or laboriously adjusting each roller station manually. This process is time-consuming and inefficient, especially in high-throughput production environments.

Our width adjustable roll forming machine, similar like a quick change cz purlin roll forming machine, eliminates this bottleneck with a smart design that enables quick width adjustment through mechanical mechanisms. With minimal downtime, operators can reconfigure the machine to produce different panel widths—an essential feature for manufacturers serving diverse building project needs.

This adaptability allows users to respond quickly to custom orders, reduce changeover time, and minimize production interruptions. Another application is the Storage Racking Shelf Post production.

No PLC or Cutoff Required

In a continuous PU sandwich panel line, the roll former is one component of a larger automated system that includes PU foaming, curing conveyors, cutting systems, and stacking units. As such, this roll forming machine does not include a PLC or cutoff unit, as those functions are managed by downstream equipment within the complete line.

By focusing the machine purely on forming accuracy and feeding stability, we reduce complexity and increase reliability. The result is a high-performance roll former that seamlessly integrates into your existing continuous PU line infrastructure.

This design philosophy ensures that the machine performs its role efficiently—forming high-quality panel skins and feeding them into the PU foaming section without errors or misalignment.

Key Benefits at a Glance

- ✅ Customizable Width: Forming width adjustable from 1000 mm to 1250 mm

- ✅ Material Thickness: Supports 0.3 mm – 0.6 mm steel or aluminum

- ✅ Mechanical Simplicity: No PLC or cutoff required—plug-and-play into continuous PU lines

- ✅ Perfect Integration: Designed for continuous panel foaming and laminating systems

- ✅ Quick Changeover: Easily switch panel sizes to meet custom orders

- ✅ Durable Construction: Made with hardened steel rollers and heavy-duty frames

- ✅ Low Maintenance: Built for stable, long-term operation with minimal wear and tear

Built by a Trusted Chinese Roll Forming Machine Factory

As a reputable Chinese roll forming machine factory, we specialize in manufacturing equipment for the metal building materials industry. Our team of engineers and technicians has years of experience in building high-speed automatic roll forming machines for both domestic and international markets.

Every machine is custom-built according to your layout, product requirements, and integration needs. We use premium components—from roller shafts to frame bases—ensuring longevity and minimal maintenance over the life of the equipment.

Our workshop follows strict quality control standards, and each machine undergoes comprehensive testing before shipment. Whether you’re operating in Asia, Europe, the Middle East, or the Americas, we can provide local support and remote diagnostics to keep your production running smoothly.

Supporting the Global Push for Green Construction

As global demand grows for energy-efficient and insulated building materials, PU sandwich panels have become a preferred choice for residential, commercial, and industrial construction. With excellent thermal insulation, fire resistance, and structural integrity, these panels are widely used in cold storage facilities, cleanrooms, prefabricated buildings, and warehouses.

By investing in a width adjustable roll forming machine designed for continuous production, manufacturers gain a competitive edge in meeting both large-scale and custom project requirements with consistency and speed.

[…] features make our width adjustable roll forming machine especially suitable for PU insulated wall panel manufacturers seeking efficiency and […]

[…] This is the core of the entire line. Our storage rack roll forming machine uses a servo-assisted screw adjustment system for automatically adjusting the roller positions to accommodate various racking post sizes. No need to change rollers, reducing downtime and boosting productivity (Seeing Width Adjustable Roll Forming Machine). […]