UniStrut Channel Roll Former: Advancing Efficiency in Strut Channel Roll Forming

In the world of modern manufacturing and construction, efficiency and precision are essential elements for success. Strut channels play a crucial role in supporting electrical, mechanical, and plumbing systems. To meet the growing demand for high-quality and accurately formed strut channels, the Unistrut Channel Roll Former, also known as a unistrut channel roll forming machine, has emerged as a game-changing solution. This advanced and fully automatic roll forming solution revolutionizes the production process, offering unmatched efficiency, consistency, and cost-effectiveness.

Table of Contents

Applications of UniStrut Channels

What is a Unistrut Channel Roll Forming Machine?

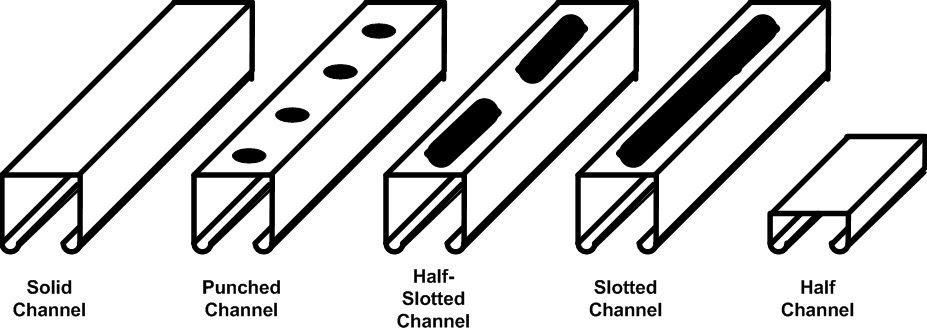

The UniStrut Channel Roll Forming Machine is a sophisticated piece of machinery designed specifically for roll forming strut channels. Roll forming is a continuous bending process that involves passing a strip of metal through multiple sets of rollers to gradually shape it into the desired profile. The Unistrut Channel Roll Former excels in forming Unistrut channels, also known as slotted channels or metal solar framing channels, which are widely used in construction for installing electrical conduits, piping, and HVAC systems.

There are different shaped profiles can be produced by different unistrut channel roll formers. For example, we can design C/U solar channel roll forming machines, Slotted strut channel roll forming machines, G type strut channel machines, C/Z solar channel roll forming machines etc.

Main component of Strut Channel Machines

The main components of a whole Strut Channel Roll Forming Machine line are key parts that will ensure the precise production of desired strut channels and solar mounting frames. The most popular and common parts are like below:

- Decoiler: Normally a 2-in-1 Decoiler and Leveller is equipped to support and unroll the steel coils automatically.

- Servo Feeder: It’s important to have a servo feeding unit to feed the materials into punching machine. Servo system ensure the accuracy of holes or slots punched.

- Punching Machine:There are usually 2 punching solutions for unistrut channel roll former, i.e. Separate Punching and Integrated Punching. For separate punching there are also 2 different solution, 110T pressing machine OR hydraulic punching unit. For Integreated Punching, Stop-to-Punch and Tracking-Punching are standard 2 options.

- Roll Forming Mill: The core and heart of strut channel machine. Roll forming mill consists of roll toolings, forming stands and driven system. The roll toolings are strategically positioned to ensure that the metal is consistently and accurately formed throughout the entire process. The forming stands are the structure where these roll toolings are mounted. Driven system or transmission system will ensures the continuous and optimal running of the whole strut channel production line.

- Cutoff Unit: Two different cutting methods are optional for cutting the finished roll formed strut channels or solar mounting frames effciently, i.e. Fly-saw Cutoff or Hyraulic Cutoff.

Collectively, these components work in harmony to deliver reliable and high-quality strut channels, proving essential for industries demanding precision and efficiency. More process at strut channel roll forming machine.

Technical Parameters of Unistrut Channel Roll Forming Machine

| Technical Parameters | Description |

|---|---|

| Machine Model | Unistrut Channel Roll Former |

| Material Thickness | 1.5 mm – 2.5 mm |

| Production Speed | Up to 25 m/min |

| Roller Material | GCr15 (High Carbon Steel) |

| Power Supply | 380V / 50Hz or customized |

| Total Installed Power | 35 kW |

| Machine Weight | Approximately 10,000 kg |

| Dimension of Machine | 25m x 1.5m x 1.5 m |

| Control System | Panasonic PLC/ HMI Control |

| Cutting Method | Hydraulic or Fly-Saw Cutting |

| Automation Level | Fully-Automatic |

| Warranty | 24 months from the installation date |

The Functionality of Unistrut Channel Roll Former

The roll former also features a robust drive system that maintains a consistent speed, enabling high production rates without compromising on the quality of the final product. The process can be automated or semi-automated, depending on the specific model and requirements, which further enhances production efficiency.

Advantages of Unistrut Channel Making Machine

Enhanced Efficiency

This Uni Strut Channel production line significantly increases production efficiency compared to traditional fabrication methods. The continuous roll forming process allows for rapid production rates, reducing lead times and increasing overall output.

Consistency and Precision

With computerized control systems and precision-engineered rollers, the Uni Strut Channel production line ensures consistent and accurate strut channel profiles. This consistency is vital for compatibility with various accessories and components used in construction and electrical applications.

Cost-effectiveness

The Uni Strut Channel Forming Machine significantly increases production efficiency compared to traditional fabrication methods. The continuous roll forming process allows for rapid production rates, reducing lead times and increasing overall output.

Automation

This UniStrut Channel production line significantly increases production efficiency compared to traditional fabrication methods. The complete automation production process from Decoiling, Holes or Slots punching, Roll forming and Final Cutoff allows for rapid production rates, reducing lead times and increasing overall output.

Integration with Accessories

With computerized control systems and precision-engineered rollers, the Uni Strut Channel production line ensures consistent and accurate strut channel profiles. This consistency is vital for compatibility with various accessories and components used in construction and electrical applications.

Ready to order? Check our Strut Channel Roll Forming Machine for Sale

Strut Channel Roll Forming Machine for Solar – Direct from MTC Factory

High-end strut channel roll forming machine for producing solar mounting framing channels with exceptional precision and durability. Gearbox-driven machine ideal for Unistrut channels 41×21 and 41×41, featuring cast-iron stands, integrated hydraulic tracking punching, and automatic cutoff. High-performance, automated, and precise.

We also offer C and U solar channel roll forming machines to meet diverse construction and solar mounting needs. Perfect for solar panel installation, construction projects, and customized framing solutions. Reliable, efficient, and easy to operate, with a 24-month warranty to ensure worry-free production.

26 in stock

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of roll forming solutions, including various metal forming related equipment in China.