Standing Seam Roof Panel Machine | The Ultimate European-Standard Roll Forming Solution

Standing seam roofing has become one of the most popular solutions for modern architecture, industrial warehouses, and commercial facilities. Its sleek appearance, hidden fasteners, and exceptional weather performance make it the go-to choice for architects and contractors. At the heart of producing such high-quality panels lies the Standing Seam Roof Panel Machine – Premium Type, a precised roll forming system built to deliver reliability and flexibility.

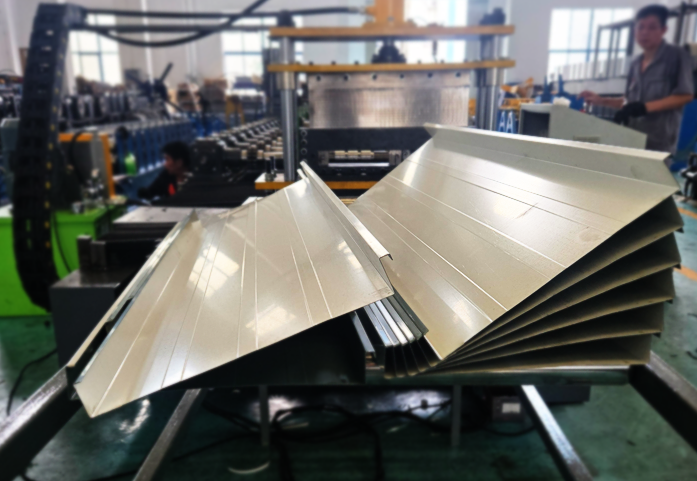

This premium machine is more than just a piece of equipment — it’s an investment in long-term production stability. Designed according to European quality standards, it is engineered to produce roofing panels with thicknesses ranging from 0.5–0.9 mm, widths adjustable between 350–800 mm, and a rib height of 60 mm. With its cast-housing stand structure, HT180 gearbox transmission, width adjustment mechanism, and hydraulic tracking cutter, it stands out as the perfect solution for manufacturers who demand durability, accuracy, and ease of use.

Table of Contents

Technical Specifications: Designed for Precision and Flexibility

A key advantage of this standing seam roll forming machine is its ability to handle a wide variety of materials and project requirements.

- Material Compatibility: Galvanized steel, pre-painted steel, aluminum, and other roofing-grade metals

- Material Thickness: 0.5 mm to 0.9 mm – covering the most common roofing sheet thickness range

- Panel Width: Fully adjustable between 350–800 mm, allowing one machine to produce panels for multiple building types

- Rib Height: 60 mm standing seam profile, ensuring superior strength and watertight performance

- Drive System: HT180 gearbox transmission for smooth and powerful forming

- Cutting System: Hydraulic tracking cutter for continuous, precise length control without stopping the line

By integrating width-adjustment technology, this premium roll forming machine eliminates the need to purchase multiple machines for different panel sizes. These panels are usually used as rooftop panels, but sometimes also they can be used as metal siding as long as PU foam is insulated. This not only saves floor space but also reduces tooling costs and setup times, making it ideal for manufacturers with diverse project requirements.

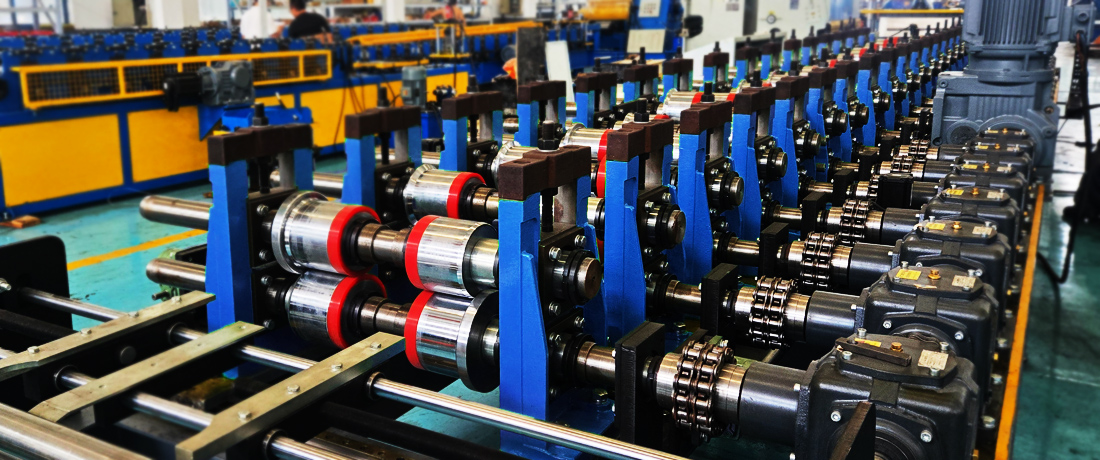

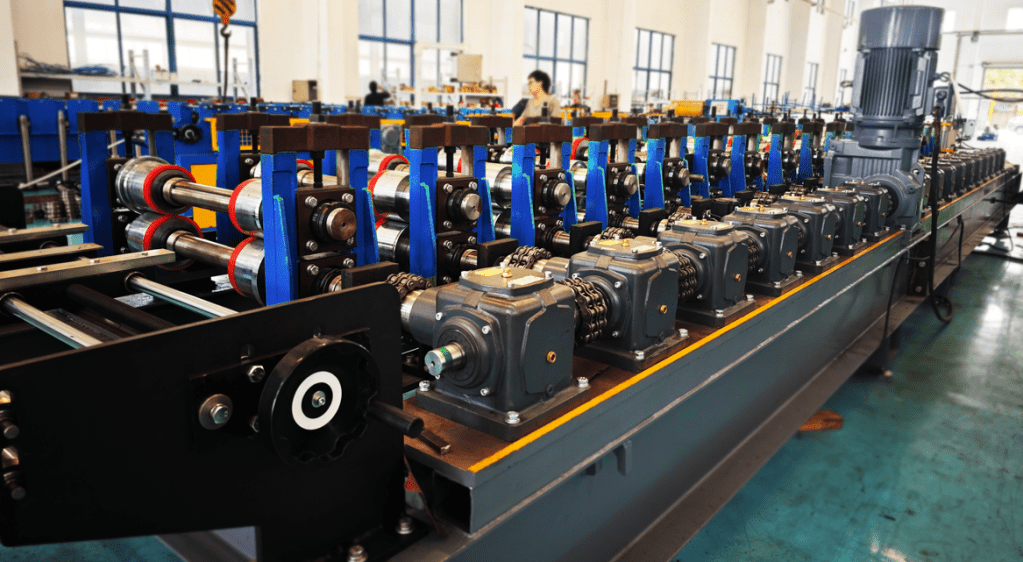

European-Standard Mechanical Structure

What truly sets this standing seam roll forming machine apart is its cast-housing stand structure. Traditional standing seam roof panel roll forming machines often use welded frames, which may deform over time under heavy production loads. Cast-housing stands, on the other hand, provide superior rigidity, maintain precise roll alignment, and minimize vibration during operation.

The machine also features gearbox-driven transmission rather than chain transmission, a feature commonly found in European quality roof panel machines. This results in:

- Higher forming accuracy – thanks to synchronized roll movement

- Reduced maintenance needs – no chain lubrication or periodic tensioning required

- Lower noise levels – creating a better working environment

This combination of heavy-duty cast stands and gearbox drive ensures a service life of over 20 years with proper maintenance, making it a true long-term investment for your factory.

Hydraulic Tracking Cutter: Precision at High Speed

An essential feature for modern production lines is the ability to cut panels accurately without interrupting the forming process. The hydraulic tracking cutter standing seam machine achieves this by following the panel as it moves, cutting it to the programmed length while the line continues running.

This technology offers several benefits:

- No production stops – increasing efficiency and reducing cycle times

- Perfectly square cuts – improving panel fitment and reducing waste

- Minimal burrs – resulting in clean, professional-looking panel edges

- 30m/min high speed – Non-stop cut and gear box stable transmission

Combined with Siemens PLC control, this system ensures every panel meets exact specifications, even during long production runs.

Easy Operation with Siemens PLC Control

User-friendly operation is a priority for this standing seam roof panel roll forming machine. The integrated Siemens PLC control system allows operators to set panel length, batch quantity, and width adjustments through a touchscreen HMI.

Key advantages include:

- Automatic length measurement – using an encoder for high precision

- Batch counting and automatic stop – preventing overproduction

- Easy troubleshooting – with error codes displayed on screen

- Multi-language support – perfect for global users

The result is a metal roof roll forming machine that is easy to operate, even for less experienced staff, reducing training time and potential for human error.

Rollers: Fine Machining and Polyurethane-Coated Support

The heart of any roll forming machine lies in its rollers. The Standing Seam Roof Panel Machine – Premium Type is equipped with rollers that are CNC precision machined to guarantee perfect panel geometry. Additionally, the rollers are supported by polyurethane roller attachments, which help reduce scratches on coated materials and extend tooling life.

This attention to detail ensures that the final standing seam panels have a flawless finish and meet the highest aesthetic requirements.

Benefits for Manufacturers and Contractors

Investing in a premium standing seam roof panel machine delivers tangible benefits:

- Long-Term Reliability: 20-year design life reduces downtime and replacement costs

- Production Flexibility: Adjustable width and programmable length meet custom project needs

- High Output & Efficiency: Hydraulic tracking cutter allows continuous production

- Low Maintenance: Gearbox transmission and cast stands minimize wear and tear

- Superior Panel Quality: Fine-machined rolls and precise cutting deliver consistent, watertight panels

This combination of durability, flexibility, and ease of use makes it ideal for metal building manufacturers, roofing contractors, and construction companies looking to expand their product range and improve competitiveness.

Applications: Where This Machine Excels

Panels produced by this European-standard standing seam roof panel machine are widely used in:

- Commercial buildings and shopping malls

- Industrial warehouses and logistics centers

- Residential villas and modern homes

- Airports, stadiums, and exhibition halls

- Public buildings and government projects

The 60 mm high rib provides excellent load-bearing capacity, while the hidden fastener system enhances aesthetics and prevents leakage, making it a preferred solution for premium roofing projects.

A Premium Investment for Long-Term Success

As one of leading rollforming machine manufacturers in China, we always focus on innovation of high-quality machines. When it comes to standing seam roofing production, quality and reliability are non-negotiable. The Standing Seam Roof Panel Machine – Premium Type combines European mechanical design, high-precision forming, and user-friendly automation to deliver a solution that will serve your business for decades.

Whether you are a large-scale metal building manufacturer or a contractor looking to bring panel production in-house, this machine provides the perfect balance of performance, durability, and cost efficiency.

If you are searching for a high-quality standing seam roof panel roll forming machine with hydraulic tracking cutter, width adjustment, and gearbox transmission, this is the equipment that will take your production to the next level.

Standing Seam Roof Panel Machine – Premium Type | FAQ

Q1: What is a standing seam roof panel machine?

A: A standing seam roof panel machine is a roll forming line that transforms metal coils into precision standing seam roofing panels with hidden fasteners, ensuring excellent waterproof performance and a modern architectural appearance.

Q2: What panel sizes can this machine produce?

A: This premium machine can form panels with 0.5–0.9 mm thickness, 350–800 mm adjustable width, and a 60 mm standing seam height, covering most commercial and industrial roofing needs.

Q3: What makes this machine “Premium Type”?

A: It uses a cast-housing stand structure, HT180 gearbox transmission, and Siemens PLC control, ensuring European-level precision, long-term stability, and a service life of more than 20 years.

Q4: How does the hydraulic tracking cutter work?

A: The hydraulic tracking cutter moves with the panel during production, allowing continuous, accurate cutting without stopping the line — improving efficiency and reducing material waste.

Q5: Is the panel width adjustable?

A: Yes. The width can be adjusted quickly and precisely, allowing manufacturers to produce multiple panel profiles without changing the entire roll set, which saves setup time and tooling costs.

Q6: What materials can be used on this roll forming machine?

A: The machine can process galvanized steel, pre-painted steel, and aluminum coils, making it versatile for a wide range of roofing projects.

Q7: How easy is it to operate?

A: Thanks to the Siemens PLC touchscreen system, operators can set panel length, batch quantity, and adjust width with minimal training, making production simple and efficient.

Q8: What is the expected service life of the machine?

A: With its heavy-duty design and precision components, the machine is built for 20+ years of continuous production with proper maintenance.