Rollforming Application in Metal Fabrication: Why It’s the Smartest Choice

Rollforming Application in Metal Fabrication: Why It’s the Smartest Choice? In today’s construction and manufacturing industries, rollforming application in metal fabrication has become one of the most efficient, cost-saving, and versatile solutions for producing steel and metal profiles. Unlike traditional fabrication methods, roll forming technology offers automation, high precision, and the ability to continuously produce large quantities of uniform parts with minimal manual intervention.

Table of Contents

Why Roll Forming Stands Out

Most of the time, when metal or steel section profiles are required, roll forming machines for steel sections are the best choice compared to other metal fabrication equipment. The reason is simple: automation and continuous running. While other machines such as press brakes, shearing machines, and punching presses have their place in metalworking, they often require multiple steps, additional handling, and manual adjustments.

By contrast, a cold roll forming line for steel profiles can perform several processes in a single pass. Bending, cutting, punching holes, straightening, and even stacking can all be done automatically. This reduces labor costs, saves working space, and ensures consistent product quality.

The metal is fed into the machine, where rollers gradually bend it into the desired shape, performing multiple operations such as cutting, punching, and straightening in a single pass. This method ensures high precision and consistency in product dimensions. The process is highly automated, reducing manual intervention and labor costs. Roll forming is particularly effective for producing long lengths of uniform components, making it ideal for applications in construction, automotive, and various industrial sectors.

Other Common Metal Fabrication Equipment

To put things into perspective, let’s look at other tools commonly used in metalworking:

- Press brakes for bending sheets into specific angles.

- Sheet shearing machines for cutting steel plates.

- Punching presses for creating holes or slots.

- Straightening machines for correcting deformations.

While each of these has its strengths, when combined they take more time, space, and operator involvement. A steel roll forming line for C and Z purlins can integrate all these processes, making it the superior choice in many applications.

Application of Roll Forming

Common Applications of Roll Forming

Roll forming machines are essential in various industries for producing complex metal parts with high precision and efficiency. This continuous process shapes materials, primarily steel, into specific profiles that are used in numerous applications. Below is a list of significant applications of roll forming machines:

- Construction Industry

- Structural Components: Roll forming machines are widely used to manufacture C and Z purlins, which are crucial for providing structural support in buildings.

- Roofing and Wall Panels: The roof and wall panel roll forming machines produce roofing sheets and wall panels that offer insulation and protection against weather elements. Their uniformity and strength are vital for durability. See more about IND panels at MAXON STEEL.

- Automotive Manufacturing

- Reinforcements and Frames: Roll forming is crucial for fabricating lightweight and durable automotive components, such as reinforcements and vehicle frames, contributing to overall vehicle safety and fuel efficiency.

- Brackets and Support Structures: These machines are used to create various brackets, which are essential for assembling different parts of a vehicle.

- Electrical Engineering

- Conduits and Enclosures: Roll forming machines are utilized to produce conduits for electrical wiring and metal enclosures for electrical components, ensuring safety and organization in electrical installations. See example of electrical conduit roll forming machine.

- Distribution Frames: Custom metal distribution frames are manufactured to house and support electrical systems in buildings.

- Furniture Manufacturing

- Metal Furniture Components: Roll forming is increasingly used to produce metal frames and components for furniture, combining design flexibility with strength and durability.

- Shelving and Racks: Stores utilize roll-formed metal strips to fabricate shelves and racks that are both functional and aesthetically pleasing. See example of shelfing rack roll forming machine.

- Railings and Fencing

- Safety Railings: Roll forming machines produce railing systems that are vital for safety in pedestrian areas and industrial settings.

- Fencing Panels: The machines are employed to manufacture ornamental fencing and security panels, showcasing both utility and design.

- Customized Applications

- Specialty Products: The flexibility of roll forming allows manufacturers to create bespoke solutions for niche markets, accommodating unique shapes and sizes as needed.

The roll forming process offers numerous advantages, including cost-effectiveness, energy efficiency, and minimal material waste. Its ability to produce high-quality, consistent products rapidly makes it a critical technology in modern manufacturing across diverse industries. As innovations continue to evolve, roll forming machines will undoubtedly maintain their significance as essential tools in metal fabrication.

The Interchangeable C/Z Steel Purlin Roll Forming Machine

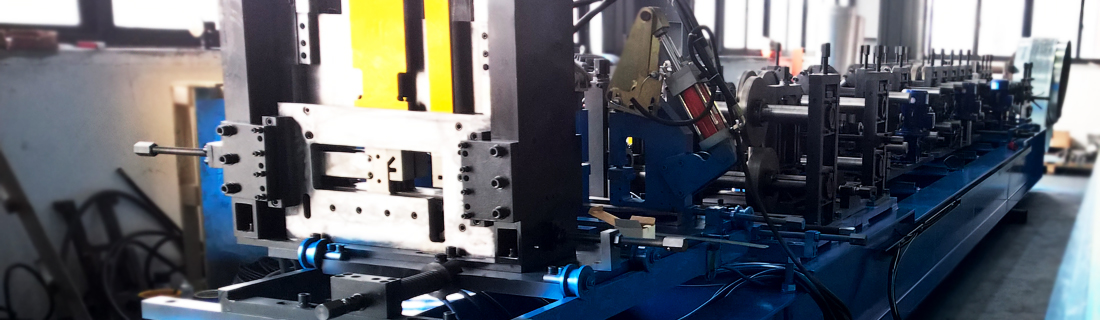

One of the most popular examples of rollforming application is the interchangeable C/Z purlin roll forming machine. This machine is designed to produce both C and Z-shaped steel sections with full automation.

Key components include:

- Decoiler

- Feeding guide

- Leveler

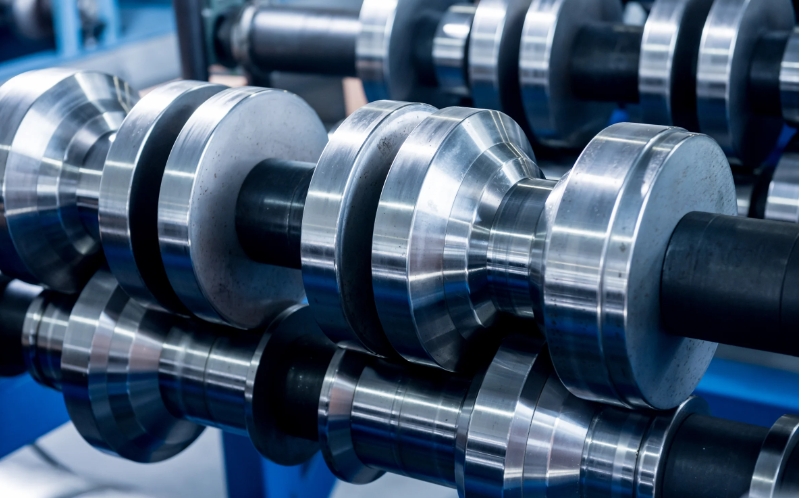

- Roll forming system

- Punching/pressing system

- Cutting system

- PLC control system

It can produce C and Z steel sections ranging from 80 mm to 300 mm in size, with punching holes and adjustable dimensions. With automated controls, switching between C and Z shapes can be done quickly, making it extremely versatile for structural steel applications.

Without such a machine, manufacturers would need separate tools like decoilers, shearing machines, punching presses, and press brakes, with several steps requiring manual operation. This increases time, cost, and the chance of errors.

Benefits of Cold Roll Forming in Metal Fabrication

A cold roll forming process for structural steel offers multiple advantages:

- Precision and Consistency – Sections are gradually shaped through a series of rollers, ensuring uniform results.

- Cost Efficiency – One machine can replace several types of equipment, reducing investment and labor costs.

- Space Saving – Consolidating multiple steps into one line minimizes the need for extra floor space.

- High Output – Continuous production increases efficiency and meets high-volume demands.

- Flexibility – Machines can be designed for different profiles, including C, Z, U, or custom shapes.

Although some fabrication equipment like press brakes and shears will always be necessary for certain tasks, automated rollforming lines for steel construction profiles remain the backbone of efficient large-scale production.

Technical Parameters (Example: C/Z Purlin Roll Forming Machine)

| Parameter | Specification |

|---|---|

| Material | Galvanized Steel, 2.0–3.0 mm thickness |

| Section Sizes | 80–300 mm (C and Z profiles) |

| Forming Stations | 14–18 stations (depending on design) |

| Motor Power | 18.5 KW + 11 KW hydraulic system |

| Punching System | Hydraulic with multiple hole options |

| Cutting System | Hydraulic, length programmable via PLC |

| Control | PLC with touchscreen operation |

These parameters can be adjusted based on client requirements, making each machine custom-built to deliver maximum value.

FAQs about Rollforming Application in Metal Fabrication

1. What is rollforming application in metal fabrication?

It refers to the use of roll forming machines to continuously shape sheet metal into specific profiles, such as C or Z purlins, with high precision and automation.

2. Why is roll forming better than press brakes or shearing machines?

Unlike traditional machines that require multiple steps, roll forming integrates bending, punching, cutting, and straightening into one continuous process.

3. Can one roll forming machine produce multiple profiles?

Yes, interchangeable C/Z purlin roll forming machines allow quick adjustments between profiles, saving both time and cost.

4. What industries benefit most from roll forming?

Construction, automotive, energy, and infrastructure industries rely heavily on roll forming due to its efficiency and ability to produce large volumes.

5. What materials can be processed with roll forming machines?

Galvanized steel, stainless steel, aluminum, and other sheet metals can all be processed, depending on machine design.

6. How accurate is the roll forming process?

Modern PLC-controlled roll formers deliver extremely high accuracy in both dimensions and punching hole locations.

7. Is roll forming cost-effective for small batch production?

While most efficient for large-scale runs, customized machines can also be designed for flexible small-batch production.

8. How long does it take to switch from C to Z purlin profiles?

In modern interchangeable lines, the switch can be completed within minutes, thanks to automated adjustment systems.

Conclusion

The rollforming application in metal fabrication has revolutionized how steel and metal profiles are produced. By integrating multiple processes into one automated line, manufacturers save time, reduce costs, and achieve greater precision. For companies looking to optimize their metalworking operations, investing in a C/Z steel purlin roll forming machine is not just a smart choice—it’s the future of efficient fabrication.