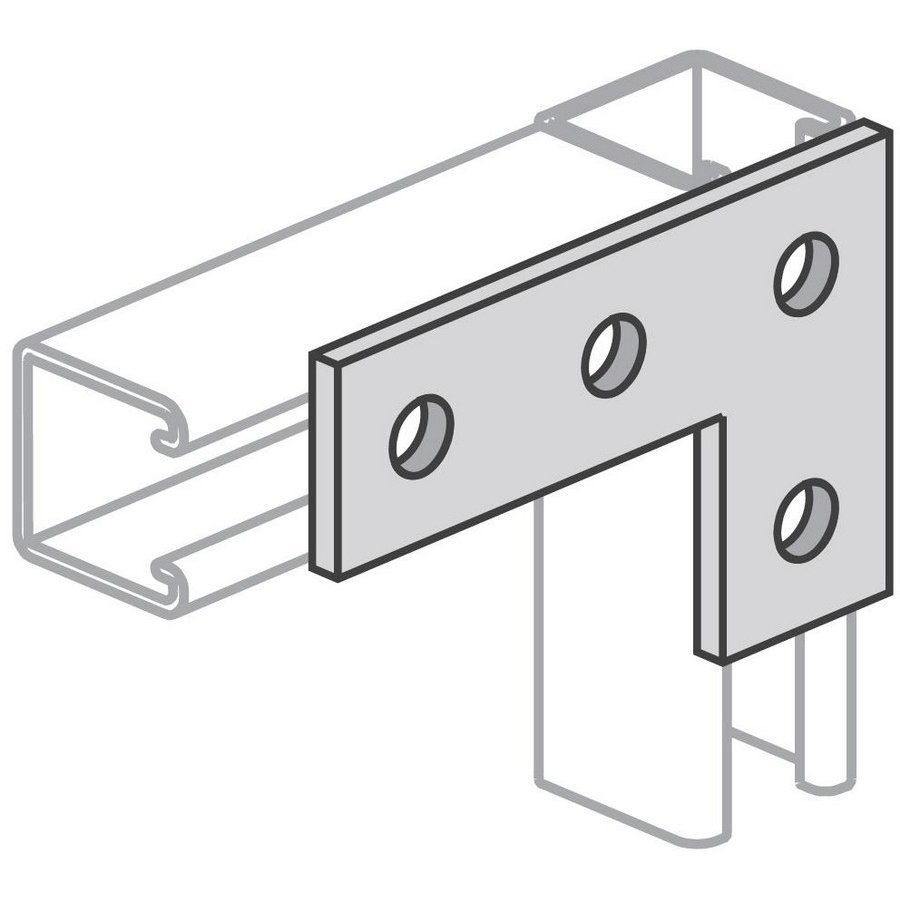

Unitrut channels, sometimes referred to as strut channels, are standardized steel profiles that allow quick assembly of support systems for electrical wiring, plumbing, HVAC, solar panels, and more.

| Type | Features | Common Applications |

|---|---|---|

| Plain Strut Channel | Solid profile | General construction support |

| Slotted Strut Channel | Pre-punched slots | Cable trays, electrical installations |

| Back-to-Back Strut Channel | Joined channels | Heavy load structures |

| Stainless Steel / Powder-Coated | Corrosion resistant | Outdoor and solar applications |

Strut channels are versatile and widely used in multiple industries.

C/U strut channels and G-type strut channels or unistrut channels are essential components in solar panel frames. They allow precise adjustment of angles and heights, accommodating various panel sizes and ensuring optimal solar exposure. These channels can be installed on rooftops or ground-mounted structures, making them ideal for both residential and commercial solar projects.

C/Z strut channels are commonly used in industrial settings for building conveyor frames, machinery supports, warehouse racking, and structural frameworks. Their modular nature allows quick assembly and modification, reducing construction time and labor costs. See more at C and Z Steel Purlins.

Strut channels support cable trays, conduits, and wiring systems in industrial and commercial facilities. Using pre-punched slots and adjustable fittings, electrical engineers can organize complex wiring layouts efficiently while maintaining safety standards.

Strut channels provide stable support for pipes, ducts, and HVAC equipment. Using standard channel dimensions and fittings, installers can create robust support systems that withstand operational loads and vibrations.

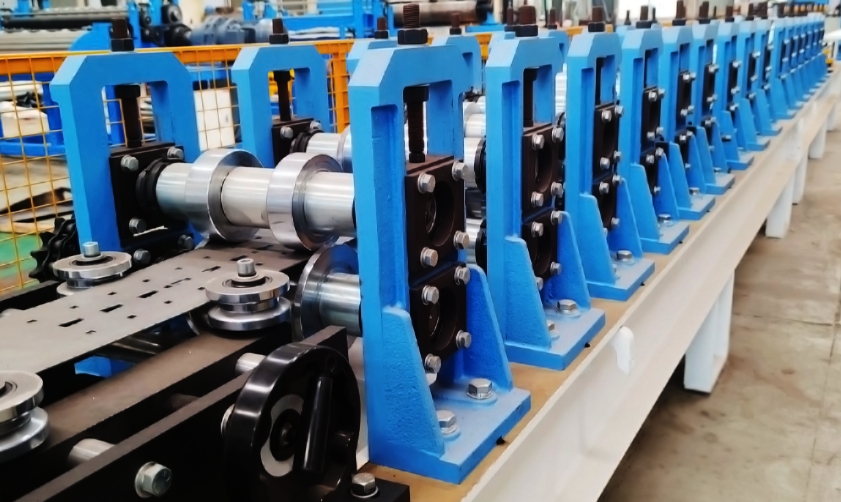

Strut channels are produced through a roll forming process to ensure high precision and efficiency:

Learn more about the process of Strut channel roll forming line.

For high-volume production, roll forming machines are ideal for creating consistent, precise strut channels.

Explore Strut Channel Roll Forming Machines →

| Method | Pros | Cons |

|---|---|---|

| Roll Forming | High speed, consistent, scalable | Requires machine investment |

| Bending/Welding | Low initial cost | Time-consuming, lower precision |

Strut channels are widely used in:

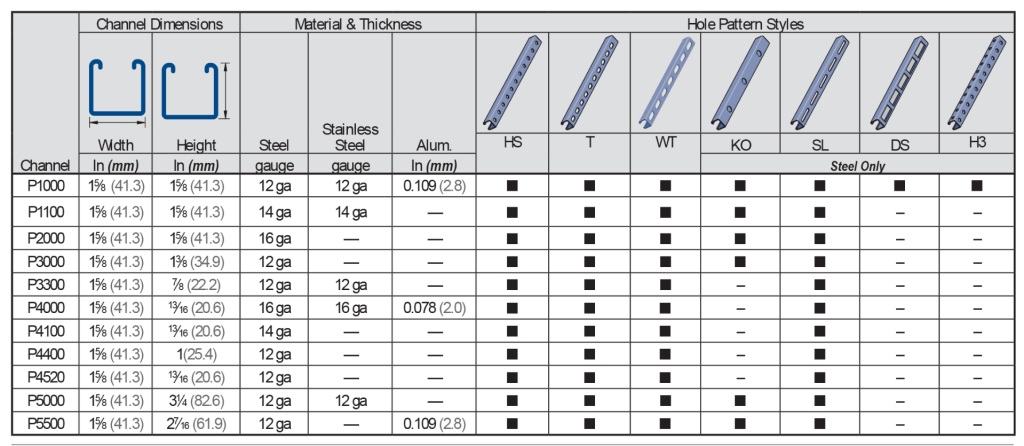

Q1: What is a standard strut channel size?

A: 41×21, 41×41, 41×61 mm are common standards.

Q2: Is strut channel the same as Unistrut?

A: Yes, “Unistrut” is a popular brand invented by ATKORE, but generic strut channels follow the same standards.

Q3: Can strut channels be used outdoors?

A: Yes, if coated or made of stainless steel for corrosion resistance.

Q4: What is the load capacity?

A: Depends on material, size, and span; refer to manufacturer specifications.

Q5: How are unistrut channels manufactured?

A: Using unistrut channel roll forming machines with punching, cutting, and optional surface finishing.

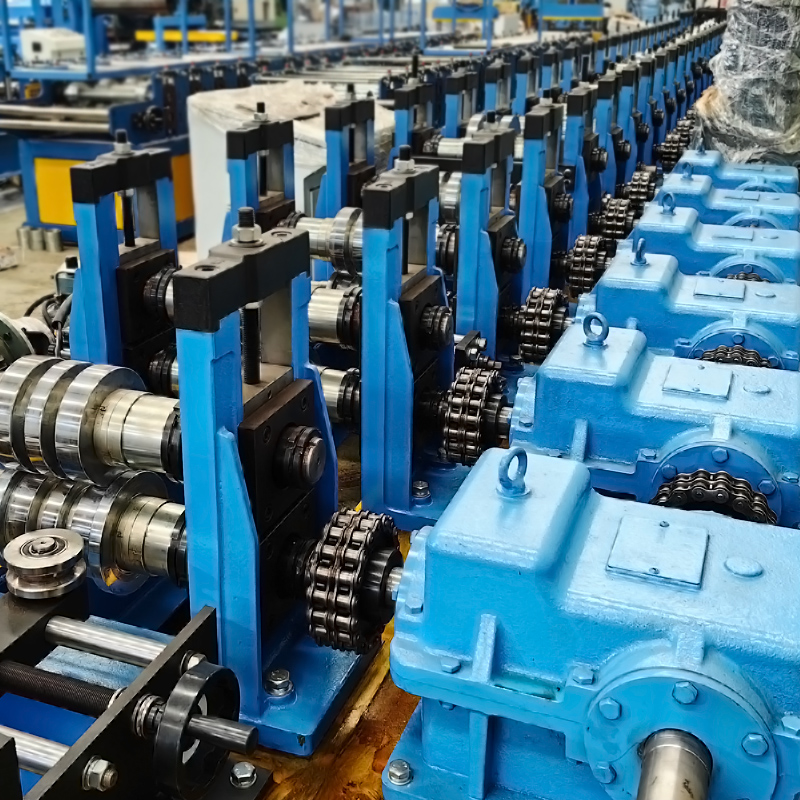

High-end strut channel roll forming machine for producing solar mounting framing channels with exceptional precision and durability. Gearbox-driven machine ideal for Unistrut channels 41×21 and 41×41, featuring cast-iron stands, integrated hydraulic tracking punching, and automatic cutoff. High-performance, automated, and precise.

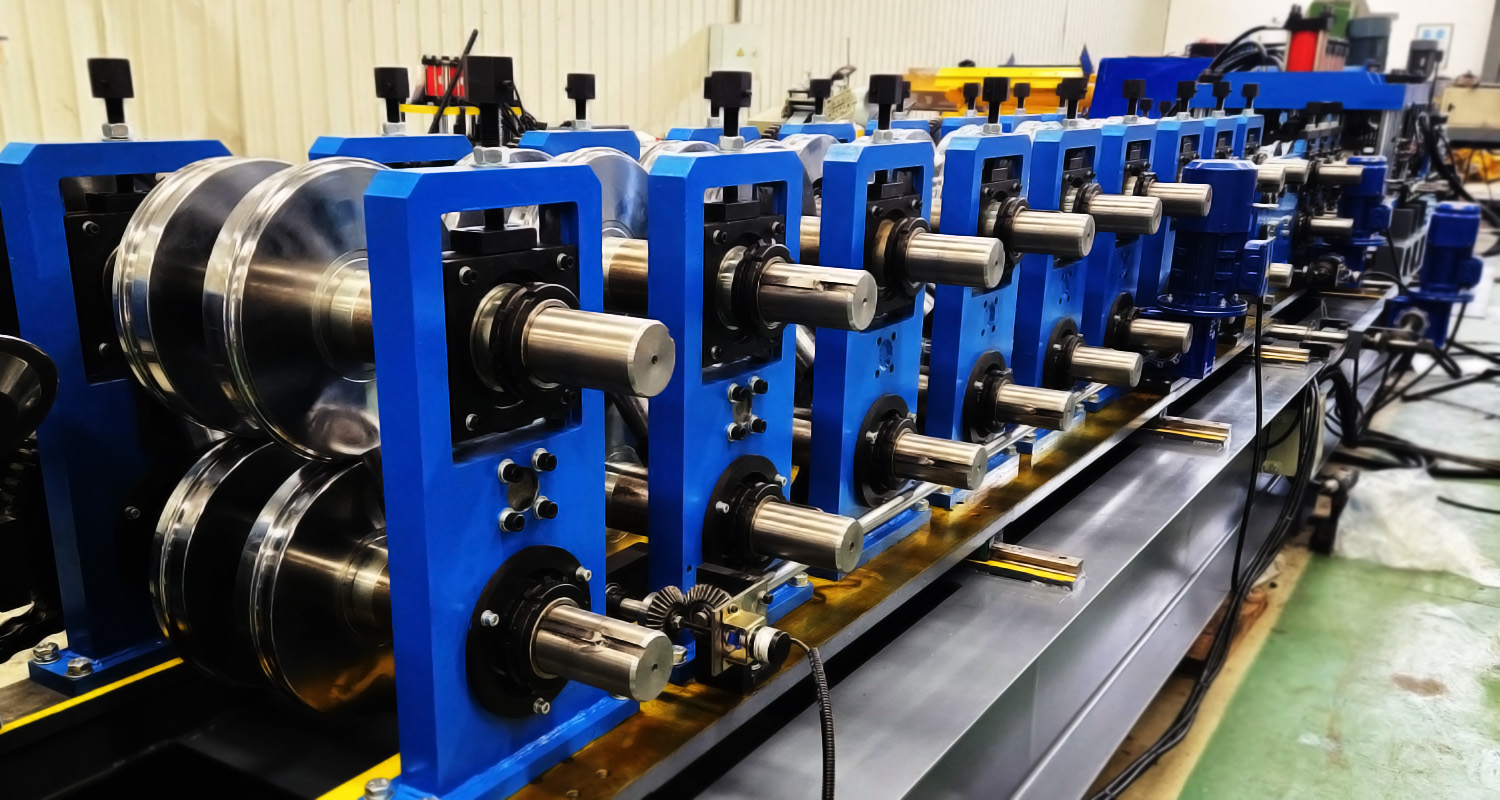

We also offer C and U solar channel roll forming machines to meet diverse construction and solar mounting needs. Perfect for solar panel installation, construction projects, and customized framing solutions. Reliable, efficient, and easy to operate, with a 24-month warranty to ensure worry-free production.

26 in stock