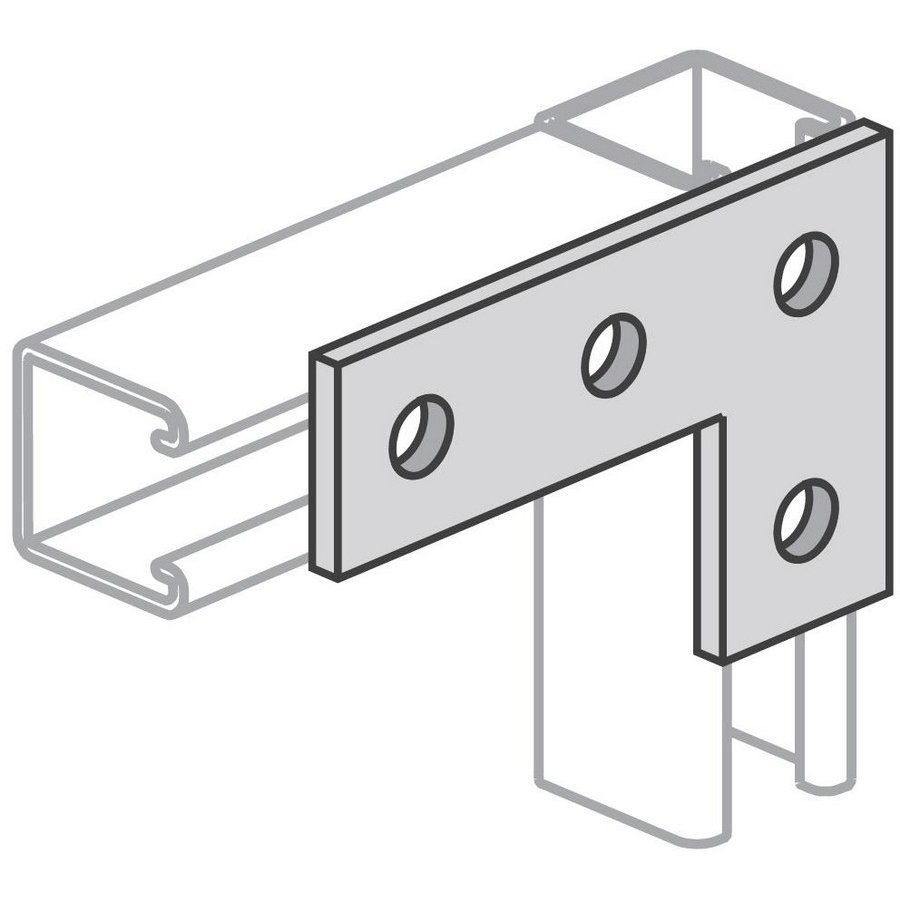

“Strut channel is a standardized formed structural system used in the construction and electrical industries for light structural support”. Unistrut channel is a specialized shape developed by Atkore. Strut is usually formed by a strut channel roll forming machine from metal sheet, folded over into an open channel shape with inwards-curving lips to provide additional stiffness and as a location to mount interconnecting components. Increasingly, strut is being constructed from fiberglass, a highly corrosion-resistant material that’s known for its lightweight strength and rigidity. Strut usually has holes of some sort in the base, to facilitate interconnection or fastening strut to underlying building structures.“

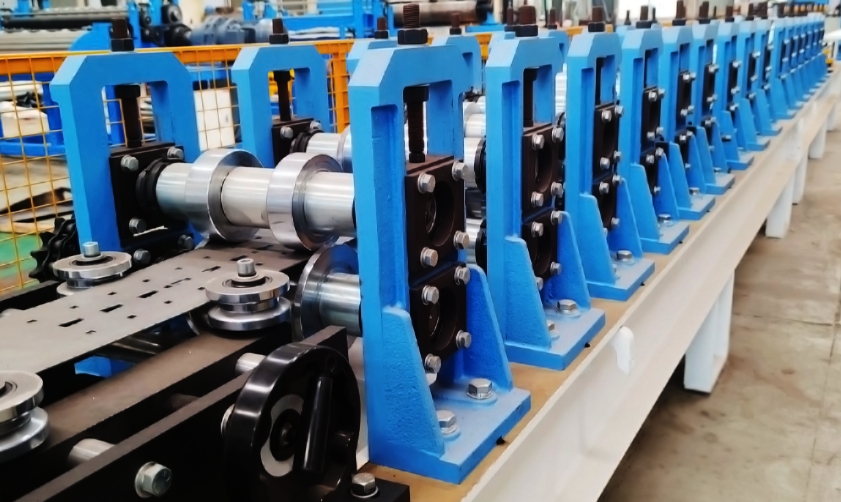

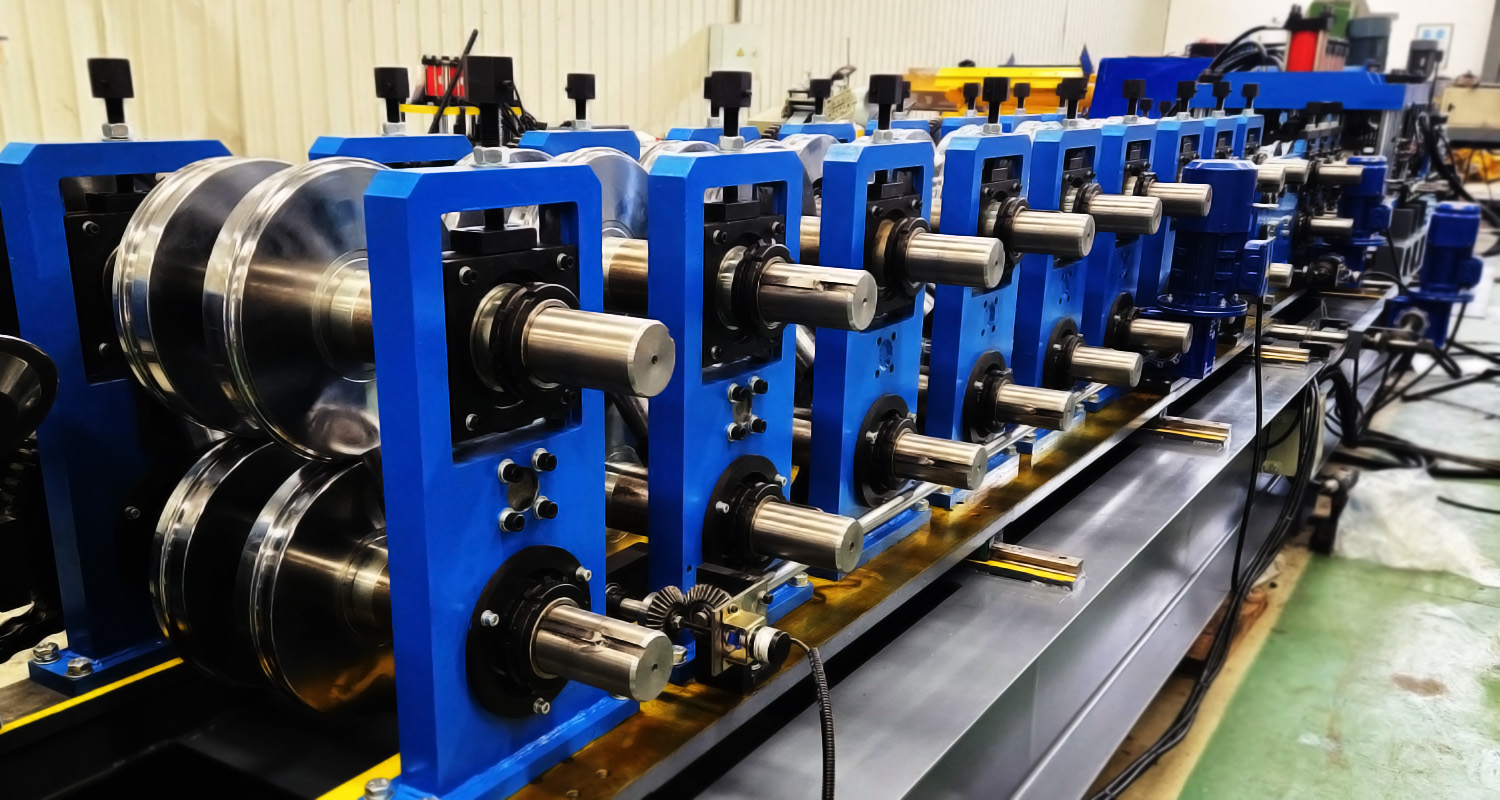

The Strut solar channel roll forming machine is a specialized industrial equipment designed for efficiently producing Strut channels—a widely used structural support system in construction and engineering applications and one unistrut channel roll former can technically produce 3 profiles by adjusting different spacers between rolling tools.

Key features of the solar strut channel roll former include its ability to handle various metal materials, such as galvanized steel and stainless steel, ensuring versatility in manufacturing. The machine typically consists of multiple rolling stations, each performing specific tasks in the forming process, ensuring a smooth and continuous production flow.

Operators can adjust the machine settings to accommodate different channel profiles and sizes, providing flexibility for diverse project requirements. The Strut channel machine significantly enhances production efficiency, reduces manual labor, and ensures the uniformity of the final product. As a result, it plays a crucial role in meeting the demands of the construction industry by delivering high-quality Unistrut channels for structural support systems.

Superior Precision and Reliability

Our roll forming machines are designed and manufactured with precision-ground rollers and heavy-duty frames to maintain tight tolerances during continuous production of solar panel mounting frames. This guarantees that every unistrut channel roll forming machine output is dimensionally accurate and structurally sound, reducing rework and waste.

Versatile Application Range

The machines are capable of producing a wide variety of strut channels used in multiple sectors, including solar energy systems, electrical conduit supports, HVAC installations, cable tray frameworks, and industrial racking systems.

User-Friendly Automation

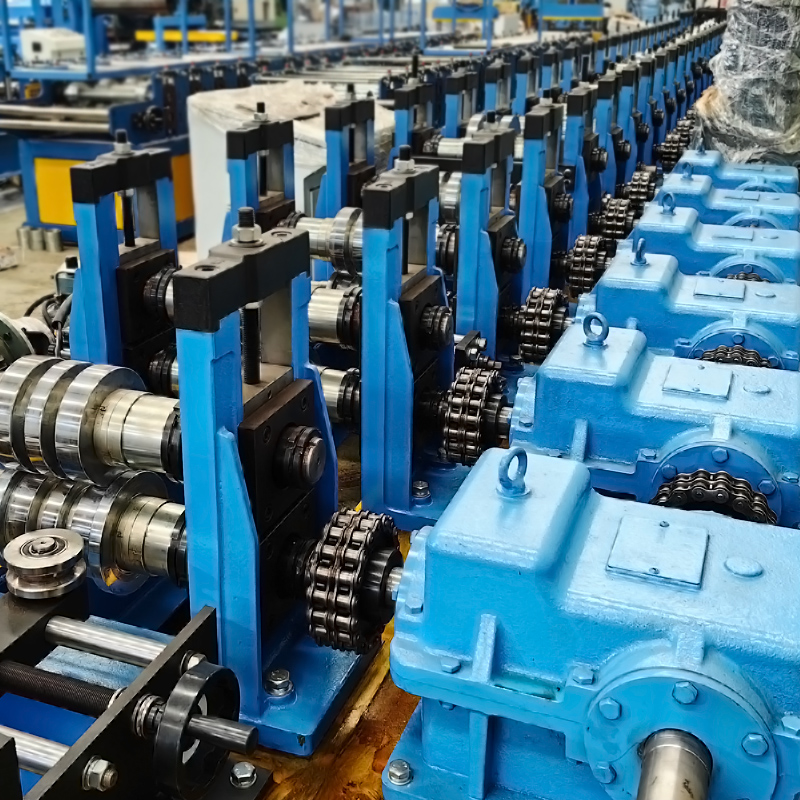

Equipped with advanced PLC controls and user interfaces, our machines offer automated feeding, cutting, punching, and stacking functions. This results in increased productivity and reduced labor costs, while ensuring safety and operational ease.

Customization and Flexibility

Recognizing that every project has unique requirements, we offer customized solutions tailored to specific profile dimensions, slotting patterns, and material specifications. Our expert engineering team collaborates closely with clients to design machines that meet their precise needs.

The Unistrut channel roll forming machine is designed for the mass production of high-precision metal strut channels, also known as framing channels or support channels. These profiles are an integral part of modern construction, electrical, and industrial support systems, offering exceptional versatility and durability.

Construction and Infrastructure – Strut channels are widely used in ceiling suspension systems, wall partitions, and solar panel roof mounting structures. Their standardized design enables fast on-site assembly without welding, reducing labor costs and installation time.

Mechanical, Electrical, and Plumbing (MEP) – They are ideal for cable tray frameworks, pipe supports, and conduit mounting, providing a secure, modular, and adaptable framework for building services.

Renewable Energy – In the solar industry, Unistrut channels are a popular choice for rooftop and ground-mounted solar panel racking systems, offering corrosion resistance and high load-bearing capacity for long-term outdoor use.

Industrial Applications – They serve in heavy-duty shelving, machinery frameworks, modular workstations, and custom equipment supports, where flexibility and reusability are essential.

The roll forming process guarantees consistent profile dimensions, smooth edges, and excellent straightness, ensuring interchangeability with a wide range of brackets, fittings, and fasteners. This makes the Unistrut channel roll forming machine a preferred investment for manufacturers supplying to commercial, industrial, and infrastructure markets.

Our strut channel roll forming machines are equipped with cutting-edge technology to ensure efficient production and high-quality output. The key specifications include:

| Technical Parameters | Specification |

|---|---|

| Material Thickness Range | 1.5 mm to 2.5 mm (Galvanized steel, stainless steel) |

| Strip Width Range | 41mm (Adjustable for various channel sizes) |

| Channel Height Range | 21/41/52/62/82mm |

| Maximum Production Speed | Up to 25 meters per minute (Depending on configurations) |

| Number of Forming Stations | 24 stations (Based on profile complexity and material specs) |

| Power Supply | Standard 380V / 50Hz (Customizable as per local requirements) |

| Machine Components | Decoiler, hydraulic punching, precision roll former, hydraulic cutter, automatic stacking system, PLC control panel |

The automation integrated into our machines ensures smooth operation, minimal downtime, and precise control over production parameters. Operators can easily adjust settings to switch between different strut channel profiles, enhancing versatility and reducing changeover time.

High-end strut channel roll forming machine for producing solar mounting framing channels with exceptional precision and durability. Gearbox-driven machine ideal for Unistrut channels 41×21 and 41×41, featuring cast-iron stands, integrated hydraulic tracking punching, and automatic cutoff. High-performance, automated, and precise.

We also offer C and U solar channel roll forming machines to meet diverse construction and solar mounting needs. Perfect for solar panel installation, construction projects, and customized framing solutions. Reliable, efficient, and easy to operate, with a 24-month warranty to ensure worry-free production.

26 in stock

Explore the common questions and answers about unistrut channel making machines

A: In most cases, strut channel machines are designed to process galvanized steel and stainless steel with thicknesses ranging from 1.5 mm to 2.5 mm.

A: Yes, the machine supports manufacturing slotted and perforated channels ideal for solar mounting frames and flexible installation needs.

A: The machine can reach speeds up to 25 meters per minute, but that depends on materials specifications, punching solutions and profile complexity.

A: Absolutely, MTC offers fully customizable machines designed to produce various channel heights, widths, and slot configurations.

A: No it won’t be at all. The whole production lines feature PLC controls with automated feeding, cutting, punching, and stacking, ensuring efficient, simple and safe operation.

A: With proper maintenance, our strut channel roll forming machines can operate reliably for over 20 years, even under high-volume production conditions.

A: Yes, MTC offers complete installation services and operator training as per required to ensure your team can run the equipment efficiently from day one.

A: Routine maintenance includes lubrication of moving parts, inspection of rollers, and checking the PLC system. We provide a detailed maintenance schedule with every purchase.