Roll Forming Machines: Revolutionizing the Greenhouse Industry

The greenhouse industry has evolved dramatically over the past few decades, driven by the need for sustainable and efficient agricultural practices. Among the technological advancements, roll forming machines have emerged as a pivotal component in the production of essential greenhouse structures such as gutters, beams, and frames. These greenhouse industry machines offer unparalleled precision, efficiency, and cost-effectiveness, making them indispensable in modern greenhouse construction. This article delves into the significance of roll forming machines in the greenhouse industry, their benefits, and how they contribute to the production of various greenhouse components.

Table of Contents

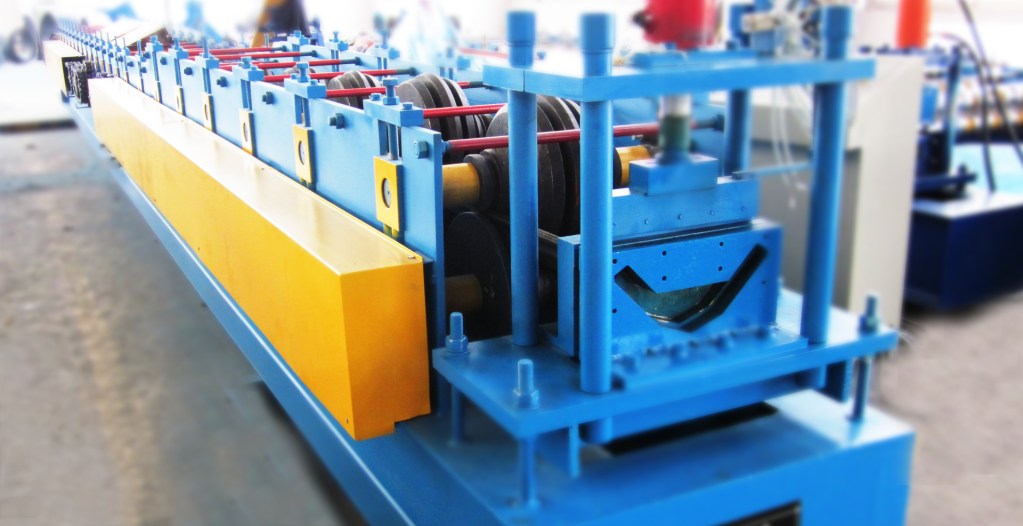

The Role of Roll Forming Machines in Greenhouse Manufacturing

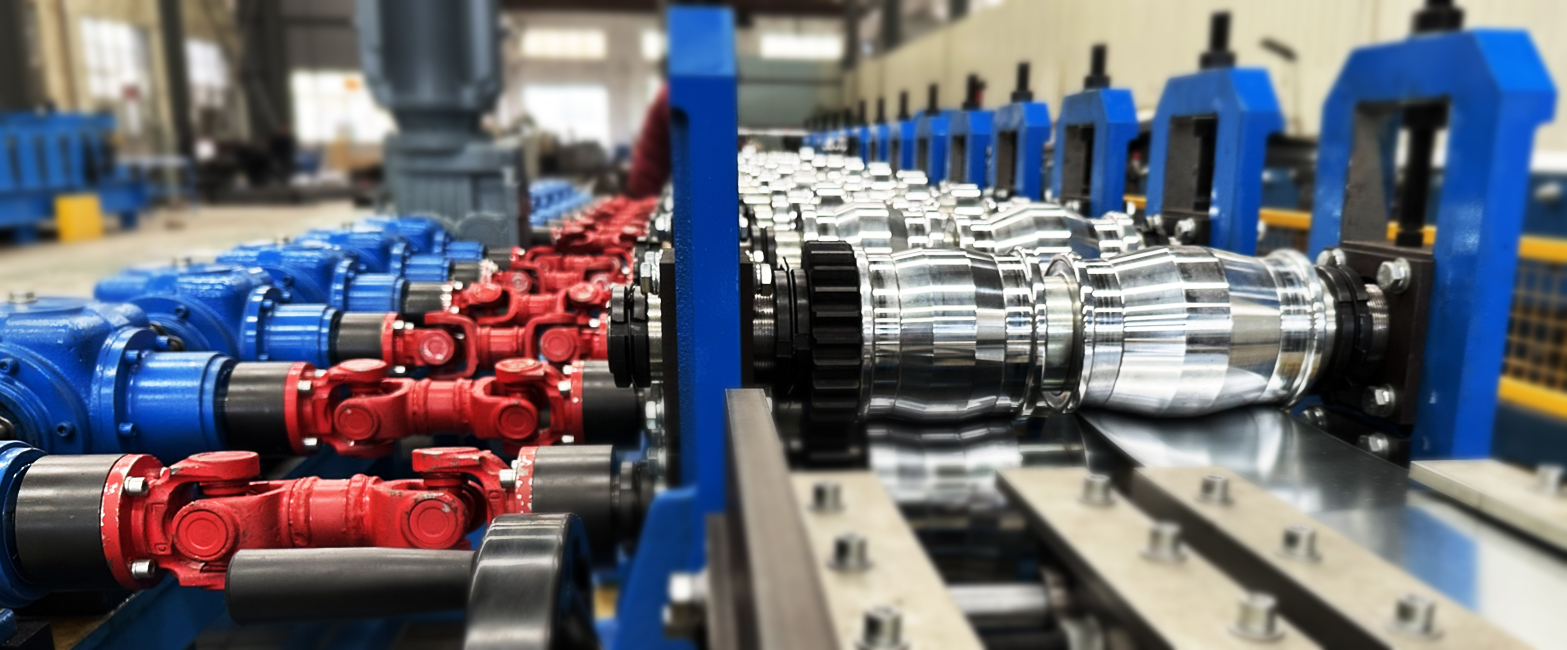

Roll forming is a continuous bending operation in which a long strip of sheet metal, usually coiled steel, is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend until the desired cross-section profile is obtained. This process is ideal for manufacturing components like greenhouse gutters, beams, and frames, which require consistent precision and durability.

Greenhouse Gutter Roll Forming Machine

Greenhouse gutters are essential for managing water runoff, preventing leaks, and maintaining the structural integrity of the greenhouse. Roll forming machines are particularly suited for producing gutters due to their ability to create long, uniform profiles with high precision. These machines can handle various materials, including galvanized steel, aluminum, and coated metals, ensuring that the gutters are not only functional but also resistant to corrosion and environmental damage.

Greenhouse Beams and Frames

The structural integrity of a greenhouse largely depends on the quality of its beams and frames. Roll forming machines can produce beams and frames with complex cross-sections, providing the necessary strength and support for the greenhouse structure. The use of roll forming in producing these components ensures that they are lightweight yet strong, facilitating easier installation and reducing overall construction costs.

Benefits of Greenhouse Industry Roll Forming Machine

Precision and Consistency

One of the primary advantages of roll forming machines is their ability to produce components with precise dimensions and consistent quality. This precision is crucial in the greenhouse industry, where even slight deviations can affect the overall performance and longevity of the structure. Roll forming machines are equipped with advanced control systems that ensure each piece meets exact specifications, reducing waste and ensuring seamless assembly.

Efficiency and Cost-Effectiveness

Roll forming is a highly efficient process, capable of producing long lengths of profiles in a continuous manner. This efficiency translates to significant cost savings, both in terms of material usage and production time. The reduced need for manual intervention and the automation of the process further contribute to lower labor costs and increased production speed, making roll forming an economically viable option for greenhouse manufacturers.

Material Versatility

Greenhouse industry roll forming machines can work with a wide range of materials, including various grades of steel, aluminum, and coated metals. This versatility allows greenhouse manufacturers to choose the best material for their specific needs, whether it’s for enhanced corrosion resistance, increased strength, or reduced weight. The ability to easily switch between materials also provides flexibility in meeting diverse customer requirements and adapting to changing market demands.

Customization and Flexibility

Modern greenhouse gutter roll forming machines are highly customizable, capable of producing profiles with intricate shapes and varying dimensions. This flexibility is particularly beneficial in the greenhouse industry, where different projects may require unique design specifications. Whether it’s creating bespoke gutter systems or custom-sized beams, greenhouse roll forming machines can be adjusted to meet specific project requirements, ensuring that each greenhouse component is perfectly tailored to its application.

Applications of Roll Formed Components in Greenhouses

Structural Frames

The structural frame of a greenhouse is the backbone of its design, providing the necessary support for the entire structure. Greenhouse profile roll forming machines produce beams and columns with precise tolerances, ensuring that the frame is strong, stable, and capable of withstanding various environmental conditions. These frames can be designed to support different types of greenhouse coverings, including glass, polycarbonate, and plastic films, enhancing the versatility of greenhouse designs.

Roof and Side Panels

Roof and side panels are critical for maintaining the internal environment of a greenhouse, regulating temperature, humidity, and light. Green house profile roll forming machines can produce panels with interlocking features, ensuring a tight seal and preventing leaks. These panels can also be designed with built-in channels for water runoff, further enhancing the functionality of the greenhouse.

Gutter Systems

Effective water management is crucial for the longevity and performance of a greenhouse. Roll formed gutters are designed to efficiently channel water away from the structure, preventing damage and reducing maintenance requirements. These gutters can be customized to fit any greenhouse design, ensuring optimal performance and integration with other components.

Support and Reinforcement Elements

Additional support and reinforcement elements, such as cross braces and trusses, are essential for enhancing the stability and strength of a greenhouse. Greenhouse industry roll forming machines can produce these elements with high precision, ensuring that they provide the necessary support without adding excessive weight. The use of high-strength materials further enhances the durability and performance of these components.

Enhancing Sustainability with Roll Forming

Sustainability is a key consideration in modern agriculture, and roll forming machines contribute to this goal in several ways:

Reduced Material Waste

The precision of roll forming machines minimizes material waste, ensuring that each piece is produced to exact specifications. This efficiency not only reduces costs but also minimizes the environmental impact associated with material waste and disposal.

Energy Efficiency

Roll forming is an energy-efficient process, particularly when compared to traditional manufacturing methods. The continuous nature of the process reduces energy consumption, contributing to a lower carbon footprint for greenhouse manufacturing operations.

Recyclable Materials

Many of the materials used in roll forming, such as steel and aluminum, are highly recyclable. This recyclability aligns with sustainable practices, allowing greenhouse manufacturers to reduce their environmental impact and contribute to a circular economy.

Roll forming machines have revolutionized the greenhouse industry, providing a highly efficient, precise, and versatile method for producing essential components. From gutters and beams to structural frames and panels, roll formed products offer numerous benefits, including cost-effectiveness, material versatility, and customization options. As the demand for sustainable and efficient agricultural solutions continues to grow, roll forming machines will undoubtedly play a crucial role in shaping the future of greenhouse construction.

By leveraging the advantages of roll forming technology, greenhouse manufacturers can enhance the quality, performance, and sustainability of their products, contributing to a more resilient and productive agricultural sector. Whether you are a greenhouse manufacturer or a farmer looking to invest in durable and efficient structures, understanding the capabilities and benefits of roll forming machines is essential for making informed decisions and achieving long-term success.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.