New Rubber Belt Continuous PU Sandwich Panel Production Line Delivered to Henan

We are pleased to announce the successful assembly of another Rubber Belt Continuous PU Sandwich Panel Production Line for a domestic customer in Henan. This advanced production line enhances manufacturing efficiency and ensures both high-quality PU insulated sandwich panels and Rockwool insulated sandwich panels with PU foam edge sealing. The line features highly-accurate machinery designed to meet the growing demand for insulated panel solutions in the construction industry.

Table of Contents

Production Line Overview

This Continuous PU Sandwich Panel Production Line is equipped with:

- Two Decoilers – Ensuring a steady supply of metal coils for uninterrupted production.

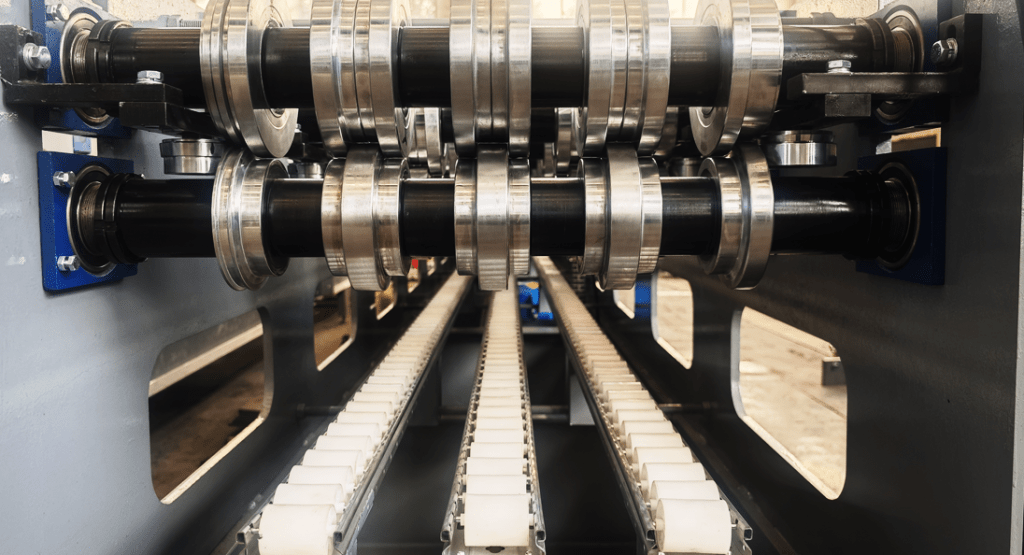

- Double Layer Roll Forming Machine – Precisely shaping the metal sheets into the required panel profiles.

- Conveyor Platforms – Facilitating smooth material flow throughout the production process.

- PU Foaming Machine – Delivering high-density polyurethane foam for superior insulation.

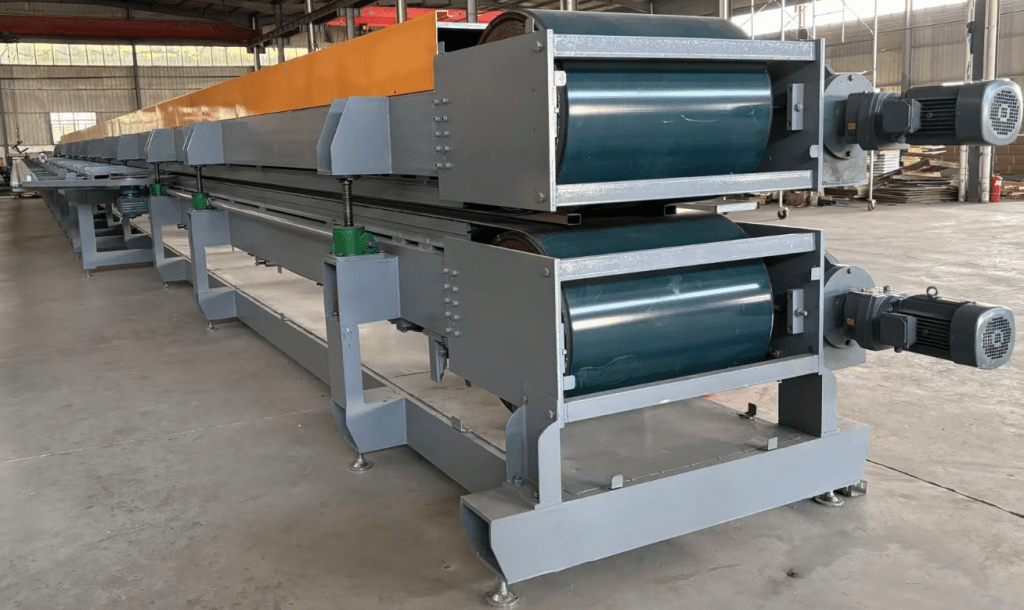

- Rubber Belt Laminating Machine (32m Length) – A critical component ensuring uniform foaming and lamination.

- Fly-Saw Servo Cutoff Machine – Enabling precise and efficient panel cutting.

- Exit Tables – Streamlining the final output for stacking and transportation.

Each component of this Rubber Belt PU Sandwich Panel Machine Line plays a crucial role in ensuring the seamless production of insulated panels. The decoilers feed raw materials into the double layer roll forming machine, which shapes the metal sheets before they move through the conveyor platforms toward the PU foaming machine. Once the foam is applied, the rubber belt laminating machine ensures even distribution and adhesion, producing a high-quality, uniform sandwich panel. Finally, the fly-saw servo cutoff machine accurately cuts panels to the desired size before they reach the exit tables for stacking and transportation.

High-Quality PU and Rockwool Sandwich Panels

This production line is designed to manufacture both PU insulated sandwich panels and Rockwool insulated wall sandwich panels, offering excellent thermal insulation, fire resistance, and durability. The Rubber Belt PU Sandwich Panel Machine Line ensures consistent quality by maintaining precise control over the lamination and curing process.

The demand for Rockwool sandwich panel production lines and PU sandwich panel production lines has been increasing due to their benefits in industrial, commercial, and residential construction. These sandwich panels are widely used in factories, warehouses, cold storage facilities, and prefabricated buildings. Their superior insulation properties contribute to energy efficiency and cost savings, making them a preferred choice for modern construction projects.

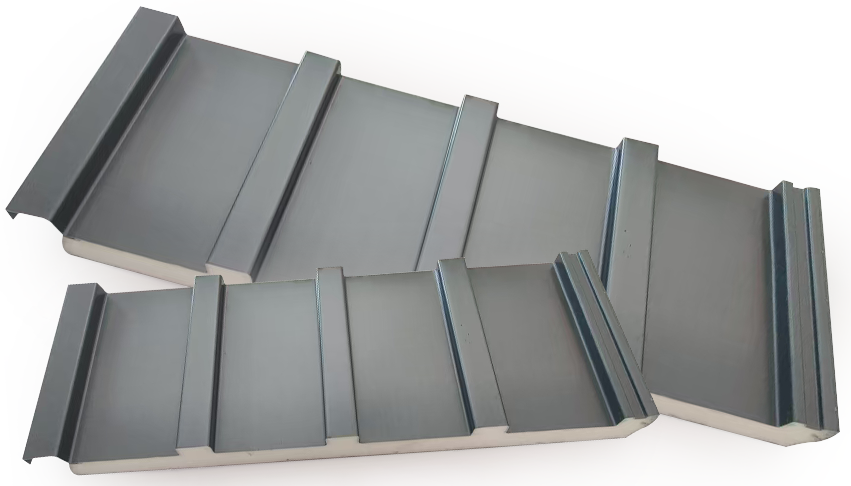

Initial Production: Aluminum PU Roof Sandwich Panels

The customer in Henan has started production with Aluminum PU Roof Sandwich Panels, featuring a fluted design. This panel type is widely used in roofing applications due to its superior insulation, lightweight structure, and corrosion resistance.

The fluted design enhances the structural strength of the panels, making them ideal for roofing applications where both insulation and durability are essential. The Aluminum PU Roof Sandwich Panels provide an excellent solution for buildings requiring weather-resistant and energy-efficient roofing materials.

Key Specifications:

- Rubber Belt Laminating Machine Length: 32 meters

- Panel Thickness Range: 45mm – 95mm

- Effective Panel Width: 500mm

- Aluminum Coil Thickness: 0.3mm – 0.6mm

Advantages of the Rubber Belt PU Sandwich Panel Machine Line

- Continuous High-Speed Production – Reduces downtime and increases efficiency.

- Superior Panel Quality – Ensures uniform foaming, lamination, and precise dimensions.

- Versatility – Capable of producing both PU and Rockwool insulated sandwich panels with PU foam edge sealing.

- Energy Efficiency – Optimized for minimal material waste and reduced energy consumption.

- Customization Options – Supports different panel thicknesses and widths to meet market demands.

- Enhanced Durability – High-quality materials and precision engineering ensure long-term performance.

- Automation and Efficiency – The integration of advanced automation technologies minimizes manual labor and enhances production accuracy.

Expanding Market Demand for PU and Rockwool Sandwich Panels

The demand for Rockwool sandwich panel production lines and PU Sandwich Panel Production Lines continues to rise, driven by the need for energy-efficient and fire-resistant construction materials. With the completion of this latest Continuous PU Sandwich Panel Production Line, our company remains committed to delivering cutting-edge manufacturing solutions tailored to industry requirements.

The Rockwool insulated wall sandwich panel line is particularly favored in industries that require fire-resistant and noise-reducing materials. Rockwool panels are widely used in power plants, high-rise buildings, and soundproofing applications due to their non-combustible nature and excellent acoustic properties.

Similarly, Polyurethane insulated sandwich panels are ideal for cold storage and industrial buildings where maintaining a controlled environment is crucial. Their superior thermal insulation helps reduce heating and cooling costs, making them a cost-effective choice for energy-conscious builders.

Why Choose Our PU and Rockwool Sandwich Panel Production Lines?

- Advanced Technology – We integrate the latest innovations to ensure high efficiency and quality.

- Customization – Our production lines can be tailored to meet specific project requirements.

- Comprehensive Support – We provide installation, training, and ongoing technical support.

- Industry Expertise – Years of experience in the field ensure top-notch manufacturing solutions.

The successful installation of this Rubber Belt PU Sandwich Panel Machine Line for our Henan customer underscores our expertise in providing top-tier PU and Rockwool sandwich panel production lines. As the industry continues to evolve, we remain dedicated to advancing sandwich panel manufacturing technology, ensuring enhanced efficiency, quality, and performance.

With continuous innovation and a focus on customer satisfaction, we are committed to being a leader in the PU and Rockwool sandwich panel production industry. If you are looking for a reliable and efficient PU Sandwich Panel Production Line, Continuous PU Sandwich Panel Production Line, or Rockwool insulated wall sandwich panel line, contact us today for more information on our latest solutions!

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.

[…] achievement—an advanced width adjustable roll forming machine specially designed for use in continuous PU sandwich panel production lines. As a leading roll forming machine manufacturer and trusted Chinese roll forming machine factory, […]