What’s the Difference Between C and Z Purlins? – 7 Key Facts You Must Know

In the world of steel structure construction, purlins play a critical role in supporting roofs and walls. But when it comes to choosing between C purlins and Z purlins, many builders and engineers are often unsure which is the better choice for their project.

Today we’ll explain the difference between C and Z purlins in detail, covering their shapes, structural properties, applications, advantages, and how specialized machines like the C purlin roll forming machine, Z purlin roll forming machine, and quick-change C/Z purlin roll forming machine make production faster and more cost-effective.

By the end, you’ll have a clear understanding of which purlin type fits your needs—and why.

Table of Contents

📌 What Are Purlins?

Purlins are horizontal structural members used in steel-framed buildings to support the roof deck or sheeting and transfer loads to the primary frame. They are typically cold-formed steel sections that are lightweight yet strong, offering excellent support over long spans.

The two most commonly used types are C purlins and Z purlins. While they may look similar, their cross-sections and structural behaviors are quite different.

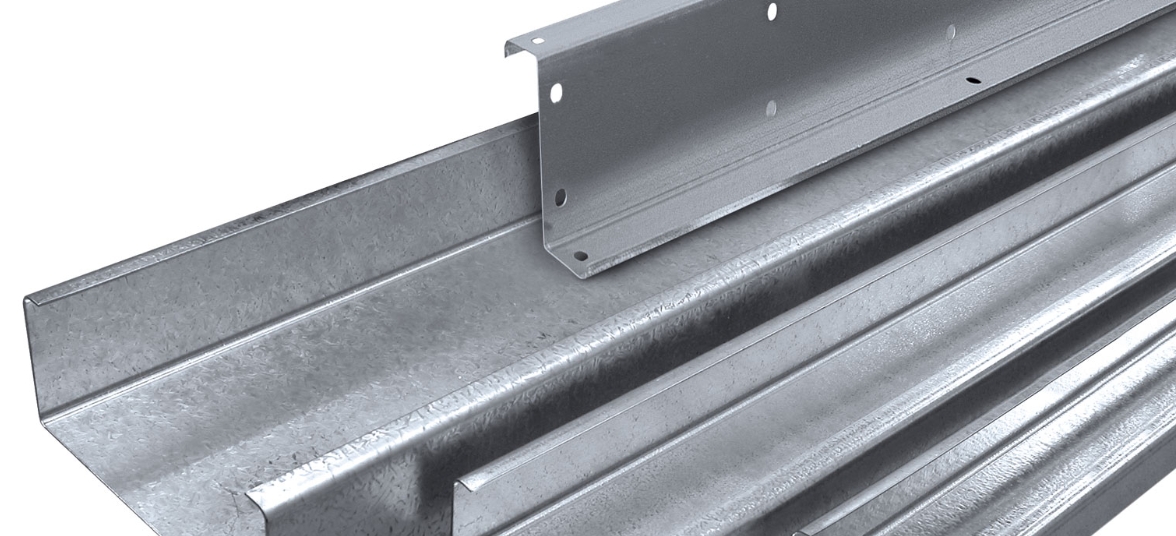

🔷 C Purlins – Overview

C purlins have a cross-section shaped like the letter “C”.

Features of C Purlins:

- Symmetrical shape with parallel flanges.

- Usually installed with the open side facing down.

- Easy to handle, install, and align.

- Ideal for simple, short-to-medium span applications.

Typical Sizes:

C purlins come in various web heights, flange widths, and thicknesses, typically ranging from:

- Web height: 80–300mm

- Thickness: 1.5–3.0mm

- Flange width: 30–100mm

Applications:

✅ Roof purlins

✅ Wall girts

✅ Mezzanine floors

✅ Canopies, carports, and small warehouses

🔷 Z Purlins – Overview

Z purlins, as the name suggests, have a cross-section shaped like the letter “Z”.

Features of Z Purlins:

- Asymmetrical shape with offset flanges.

- Designed to overlap at joints for better continuity.

- Stronger over longer spans due to their overlapping ability.

- Require careful orientation during installation.

Typical Sizes:

Similar to C purlins, but with the ability to lap sections.

Applications:

✅ Large industrial buildings

✅ Long-span roofs

✅ Complex steel structures

🔷 7 Key Differences Between C and Z Purlins

| Aspect | C Purlin | Z Purlin |

|---|---|---|

| Shape | Symmetrical C shape | Asymmetrical Z shape |

| Strength over long spans | Less efficient | More efficient due to lapping |

| Lapping capability | Cannot lap | Can overlap to create continuous support |

| Installation | Easier, no orientation issues | Requires correct orientation |

| Cost | Slightly cheaper for short spans | More cost-effective for long spans |

| Best for | Short-to-medium span projects | Large, long-span roofs |

| Machine required | C purlin roll forming machine | Z purlin roll forming machine |

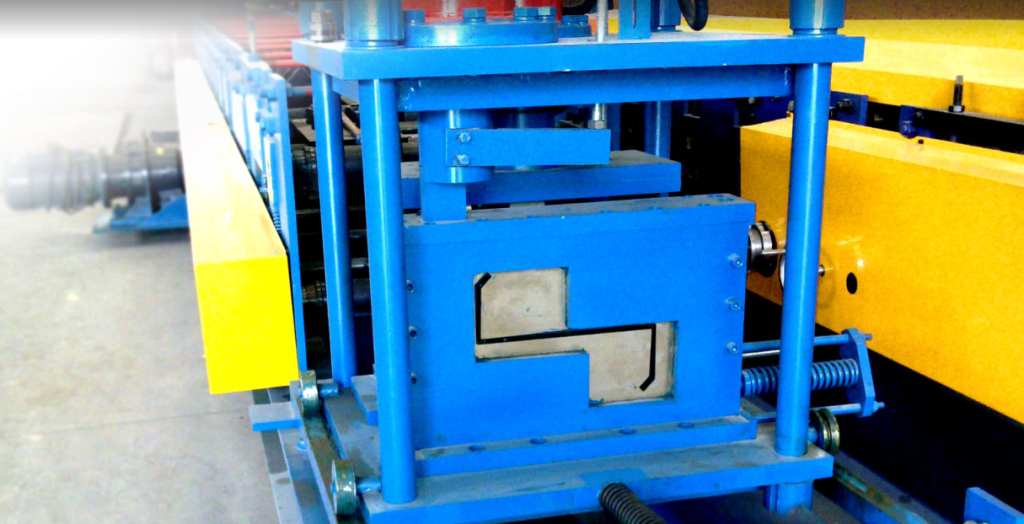

🛠️ How Are C and Z Purlins Made?

Both types of purlins are produced using specialized roll forming machines. These machines take flat steel coils and form them into the desired profile through a series of roller dies.

C Purlin Roll Forming Machine

- Designed specifically to form C-shaped purlins.

- Can produce adjustable web heights and flange widths.

- Simple operation, high efficiency for standard C profiles.

Z Purlin Roll Forming Machine

- Specially designed rollers to produce asymmetrical Z shapes.

- Allows precise control of offset flanges for proper overlapping.

Quick-Change C/Z Purlin Roll Forming Machine

For manufacturers who need to produce both C and Z purlins, the quick-change C/Z purlin roll forming machine is the ideal choice.

✅ Switch between C and Z profiles in as little as 3–5 minutes without changing roller sets.

✅ Ideal for contractors who work on projects requiring both purlin types.

✅ Reduces downtime and increases production flexibility.

Tip: If your business serves a variety of construction projects, investing in a quick-change machine can save significant time and money in the long run.

📈 Which Purlin Should You Choose?

When deciding between C and Z purlins, consider the following factors:

✔ Span length – For longer spans, Z purlins with lapping are more efficient.

✔ Ease of installation – If you want quick and easy installation, C purlins are preferred.

✔ Cost-effectiveness – For short-to-medium spans, C purlins are more economical. For larger buildings, Z purlins reduce material usage.

✔ Structural design – Always consult your structural engineer to determine the most suitable option for your project.

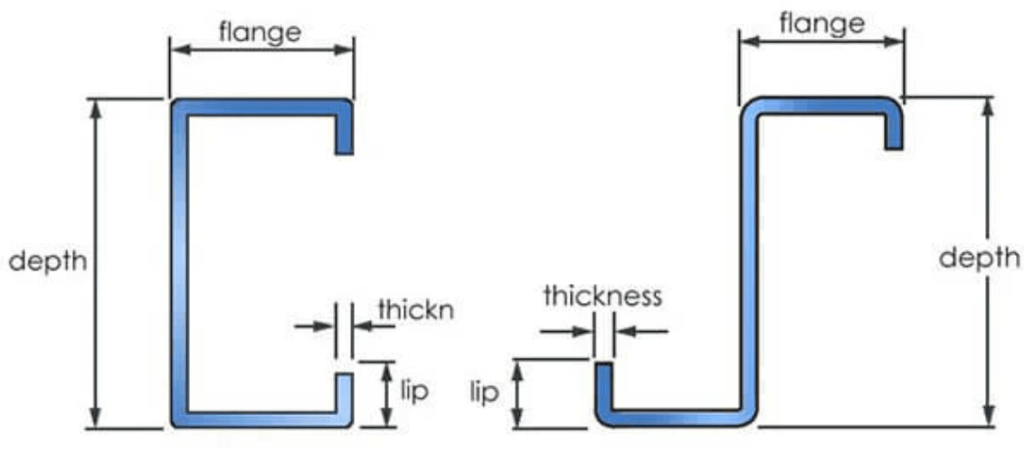

📷 C vs. Z Purlins: A Visual Comparison

Here’s a side-by-side comparison to help you visualize the difference:

C Purlin Cross-Section VS. Z Purlin Cross-Section

🤝 Our Expertise in Purlin Roll Forming Machines

We specialize in designing and manufacturing all types of purlin roll forming machines, including:

- C Purlin Roll Forming Machine

- Z Purlin Roll Forming Machine

- Quick-Change CZ Purlin Roll Forming Machine

All machines are built with durable materials, advanced PLC control systems, and precise roller dies to deliver consistent, high-quality purlins at high production speeds.

🚀 Conclusion: Make the Right Choice for Your Project

Both C and Z purlins have their unique advantages. The key is to match the purlin type to your specific project requirements. With the right purlin roll forming machine, you can produce the profiles you need quickly, efficiently, and cost-effectively.

If you’re looking to invest in a reliable, high-performance roll forming machine, we’re here to help. Contact us today for a free consultation and discover how our solutions can help your business grow.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.