Strut Channel Machine Roll Forming: Revolutionizing Construction Industry

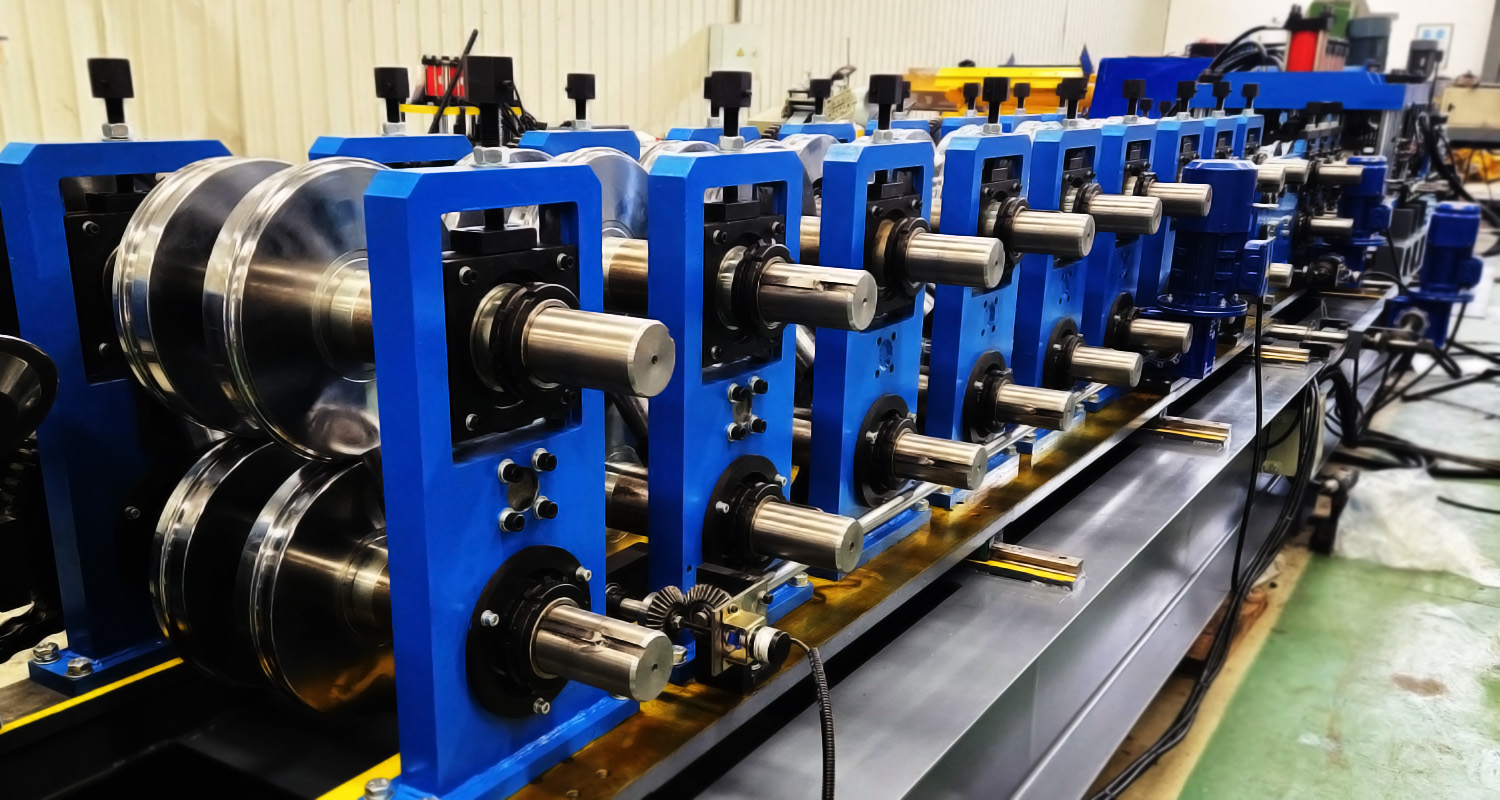

Introduction of Unistrut Channel Roll Forming Machine

In the ever-evolving world of construction and infrastructure development, efficiency and precision are paramount. One technology that has significantly contributed to streamlining the construction process is the Strut Channel Roll Forming Machine. This innovative piece of strut channel machine has transformed the way we create support structures for electrical and plumbing systems, offering numerous benefits that enhance construction projects’ overall quality and efficiency.

Table of Contents

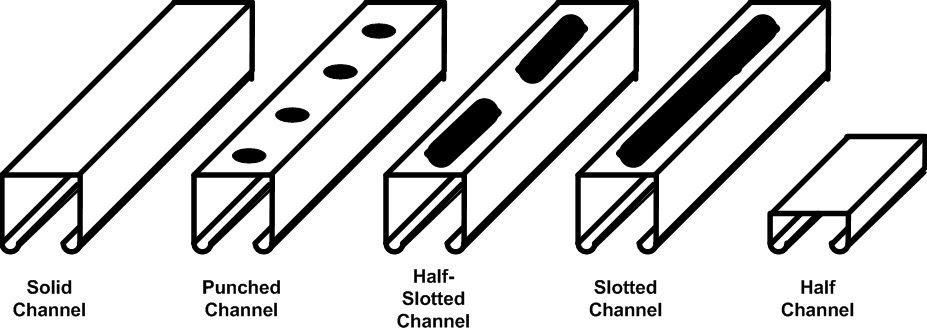

What Are Strut Channels and Why Are They Important?

Strut channels, also known as Unistrut channels or metal framing channels, are widely used in modern construction to provide robust support for a variety of building systems. They serve as a framework to mount, support, and organize electrical wiring, pipes, ducts, and mechanical equipment. Due to their strength, versatility, and adaptability, solar strut channels are indispensable components in commercial, industrial, and residential construction.

Commonly made from galvanized steel, stainless steel, or aluminum, strut channels must meet strict dimensional and material standards to ensure reliability and safety. Poorly manufactured strut channels can lead to unstable installations, increased maintenance costs, and even safety hazards.

Traditional Manufacturing Methods and Their Limitations

Traditionally, the production of strut channels involved multiple manual and semi-automated processes such as cutting, drilling, welding, and assembling metal sheets or coils. While functional, these methods present several challenges:

- Inconsistency in dimensions: Manual operations increase the risk of deviations, affecting the fitting and alignment of strut channels during installation.

- High material waste: Cutting and welding processes generate significant scrap metal, raising material costs and environmental burden.

- Long production times: Multi-step operations slow down manufacturing, delaying project timelines and increasing labor expenses.

- Limited customization: Altering dimensions or profiles requires extensive retooling and setup, limiting flexibility for diverse project needs.

These drawbacks prompted the need for a more streamlined, automated solution in strut channel manufacturing.

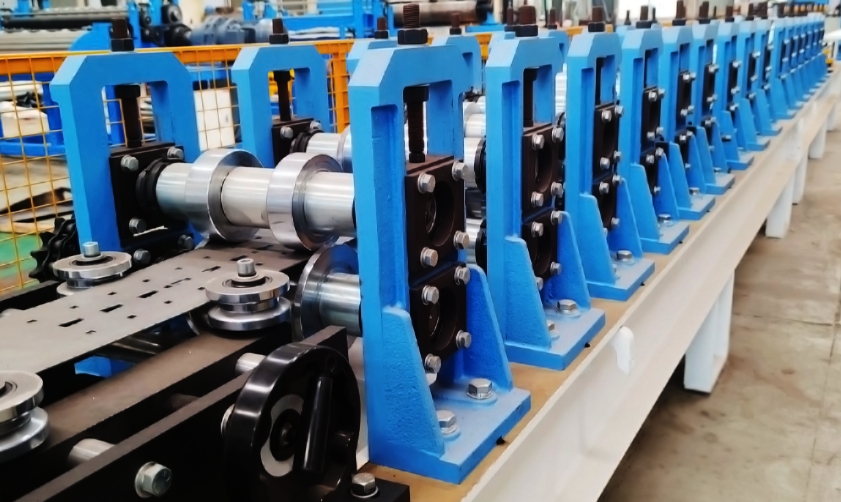

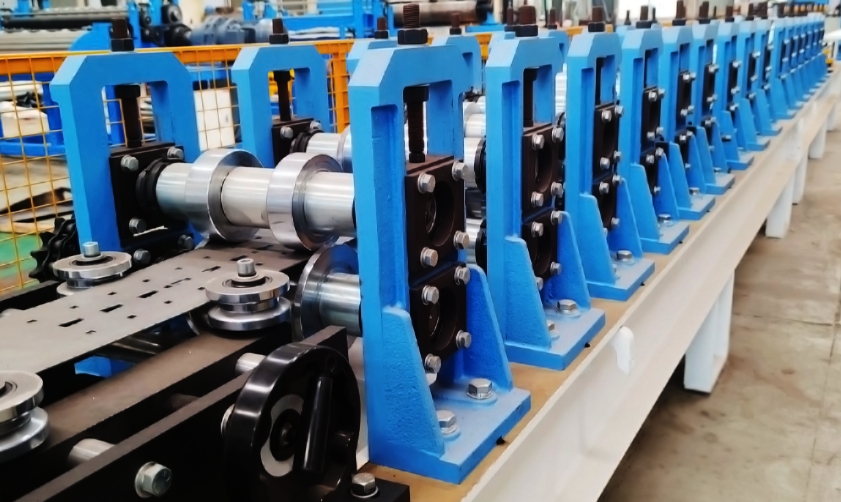

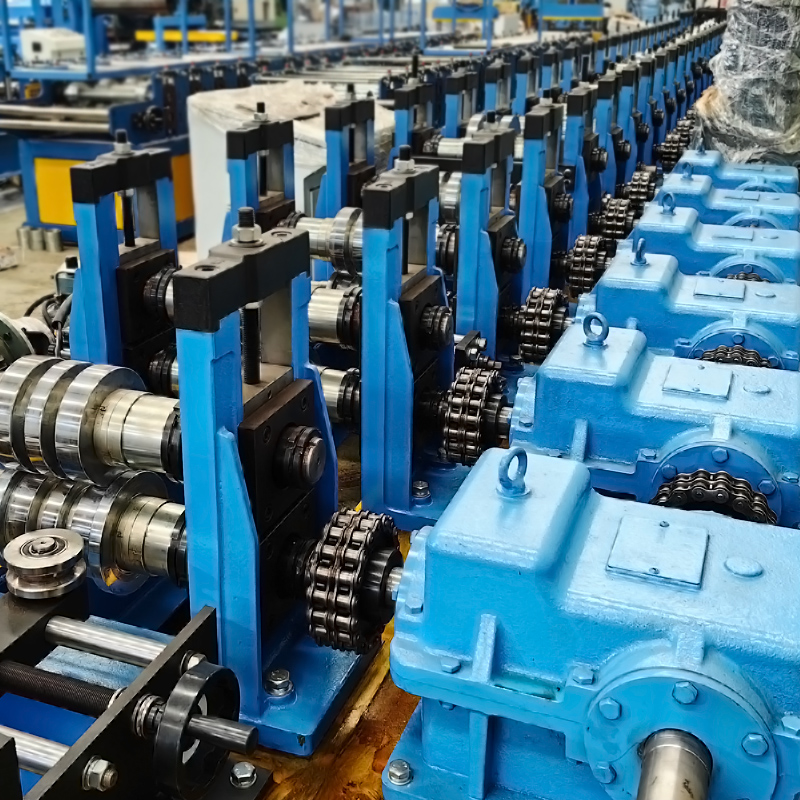

The Role of Unistrut Channel Roll Forming Machines

Enter the Unistrut Channel Roll Forming Machine — a specialized roll forming system designed to continuously shape metal coils into precise strut channel profiles. Roll forming technology uses a series of rollers that gradually bend the metal strip into the desired shape, maintaining consistent quality throughout long production runs.

The Strut Channel Roll Former Machine emerged as a solution to these challenges. This strut channel machine offers a highly efficient and cost-effective method of manufacturing strut channels by continuously shaping metal coils into the desired profiles. Let’s explore the various advantages this technology brings to the construction industry.

One of the most significant advantages of using a Solar Mounting Strut Channel Roll Forming is the precision and consistency it offers. The machine operates with exceptional accuracy, ensuring that every strut channel produced meets the required specifications.

Unlike traditional manufacturing methods, which involve extensive cutting and welding, roll forming generates minimal waste. It maximizes material utilization by shaping coils into the desired profiles without the need for additional processing. UniStrut Channel Roll Forming Machines are capable of high-speed production, significantly increasing output compared to traditional methods.

Modern Strut Channel Forming Machines offer a wide range of customization options. They can produce strut channels in various sizes, shapes, and materials, catering to the specific needs of each construction project. Strut channels manufactured using roll forming technology are known for their durability and strength.

Applications of Solar Channel Roll Forming Machines

The strut channels produced by roll forming machines find extensive applications in:

- Electrical installations: Supporting conduit pipes, cable trays, and wiring systems.

- Plumbing systems: Mounting and securing water and gas pipes.

- HVAC units: Holding air ducts, ventilation systems, and climate control equipment.

- Solar panel mounting: Forming the structural framework for photovoltaic systems.

- Industrial machinery: Creating support frameworks and safety guards.

- C/Z steel purlins: Producting steel purlins in C/Z shapes for construction fields.

The adaptability and reliability of roll-formed strut channels make them indispensable across various industries and construction types.

Technical Parameters of Unistrut Channel Roll Forming Machine

| Parameter | Specification |

|---|---|

| Machine Type | Unistrut Channel Roll Forming Machine |

| Material Thickness Range | 1.5 mm – 3.5 mm |

| Material Types | Galvanized Steel, Stainless Steel, Aluminum |

| Strip Width Range | 30 mm – 100 mm |

| Channel Height Range | 20 mm – 80 mm |

| Production Speed | Up to 25 meters per minute |

| Roll Stations | 15 – 20 sets (depending on design) |

| Power Supply | 380V / 50Hz (customizable) |

| Total Power Consumption | Approx. 15 kW |

| Machine Length | Approx. 8 – 12 meters |

| Weight | Approx. 8,000 – 10,000 kg |

| Control System | PLC with Touch Screen Interface |

| Optional Features | Automatic Punching, Cutting, Stacking |

These parameters can be customized according to specific production requirements, ensuring maximum flexibility for different projects.

Why Choose a Unistrut Channel Roll Forming Machine?

With the ability to produce customized strut channels in various sizes and materials, these machines ensure that construction projects receive precisely tailored components. Additionally, the durability and strength of roll-formed strut channels make them ideal for long-lasting support structures. Although the initial investment may be substantial, the significant long-term cost savings make the investment worthwhile for construction companies.

The Solar Channel Roll Forming Machine has revolutionized the construction industry by offering precision, efficiency, and cost-effectiveness in the production of strut channels. Its ability to create consistently high-quality components while minimizing waste has made it an invaluable tool for modern construction projects. As the demand for sustainable and efficient construction practices continues to grow, UniStrut Channel Roll Forming Machines will undoubtedly play a vital role in shaping the future of the industry, ensuring safer, faster, and more cost-effective construction processes.