Unraveling the Marvels of Roll Forming Machines: A Comprehensive Introduction

Definition of Roll Forming Machines:

Roll forming machines are sophisticated pieces of equipment utilized in metalworking industries to transform metal coils into continuous profiles with uniform cross-sections. This innovative method of shaping metal offers precision, efficiency, and versatility, making roll forming machines integral to various manufacturing processes.

Table of Contents

History and Evolution:

The concept of roll forming traces back to ancient civilizations, where rudimentary forms of metal shaping were employed for crafting tools and decorative items. However, it wasn’t until the industrial revolution that roll forming machines as we know them today began to emerge. The 19th century saw significant advancements in metalworking technology, paving the way for the development of modern roll forming machinery. Over the decades, continuous refinement and innovation have propelled roll forming machines to the forefront of metal forming technology.

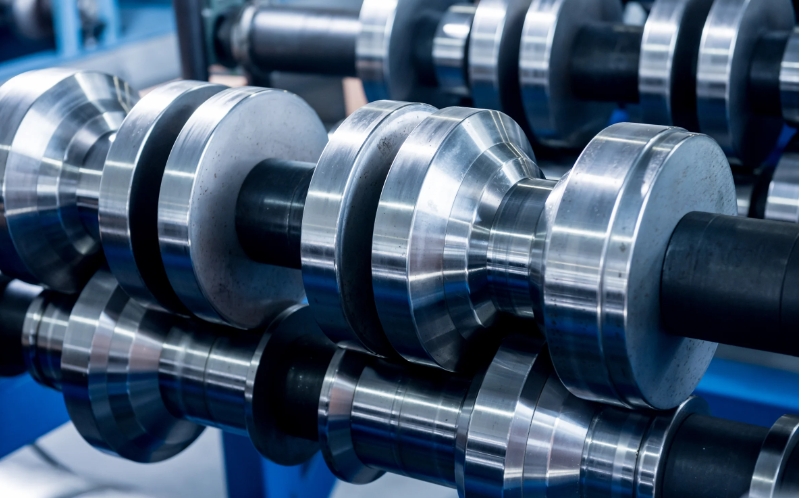

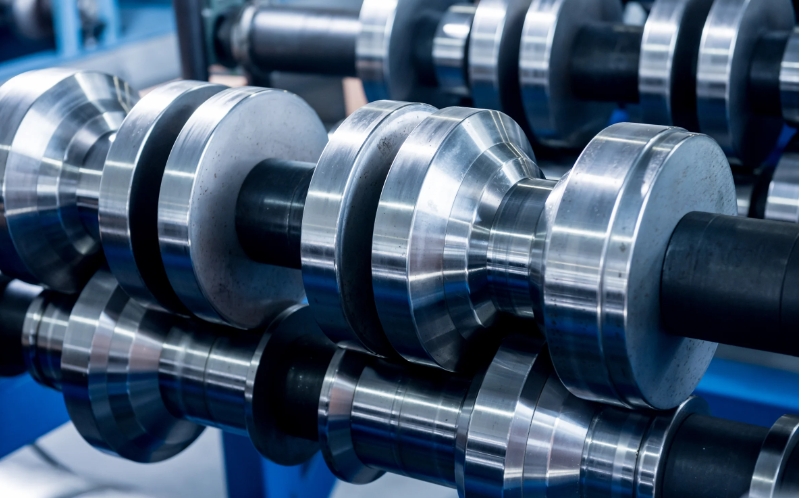

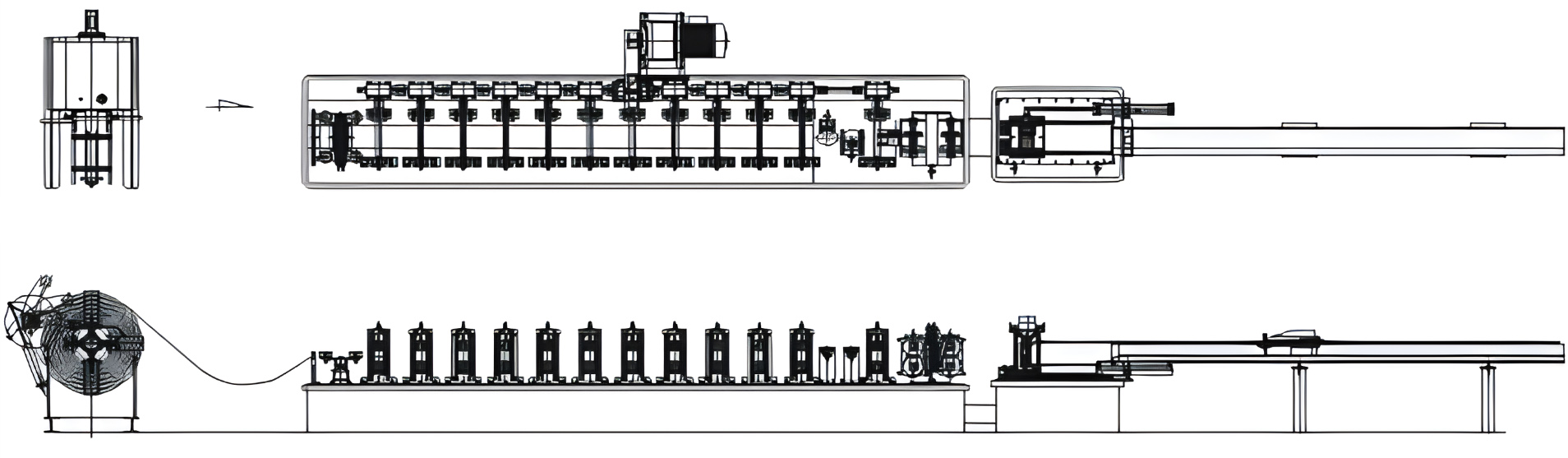

Basic Components and Working Principle:

Roll forming machines consist of several key components that work in tandem to shape metal coils into desired profiles. These components typically include an uncoiler for feeding the metal coil, a series of rollers arranged along the forming line, a cutting mechanism, and a control system. The working principle involves feeding the metal coil through the rollers, which gradually bend and shape the material to achieve the desired profile. This continuous process ensures high precision and repeatability in producing long-length components with consistent quality.

Importance in Various Industries:

Roll forming machines play a vital role in a multitude of industries, including construction, automotive, aerospace, furniture, and appliance manufacturing, among others. In the construction sector, roll-formed profiles are used in structural framing, roofing, cladding, and interior partitioning systems. In automotive manufacturing, roll forming machines produce components such as door frames, window channels, and chassis reinforcements. The versatility of roll forming machine technology makes it indispensable across a wide range of applications, contributing to the efficiency and competitiveness of various industries.

Advantages over Other Forming Methods:

Roll forming machines offer several advantages over traditional forming methods such as stamping, press braking, and extrusion. One of the key advantages is the ability to achieve complex shapes and profiles with high precision and consistency. Additionally, metal roll forming allows for continuous production, resulting in faster manufacturing speeds and reduced material waste. The versatility of roll forming machines also extends to material selection, as they can accommodate various metals including steel, aluminum, copper, and alloys.

In conclusion, roll forming machines represent a pinnacle of innovation in metalworking technology, offering unmatched precision, efficiency, and versatility in shaping metal profiles. Their importance across diverse industries underscores their significance in modern manufacturing processes, driving advancements and fueling economic growth. As industries continue to evolve, roll forming machines will remain at the forefront, shaping the future of metalworking technology.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.