Choosing Right Materials for the Cutoff Blade of Your Metal Roll Forming Machines

Selecting the right materials for cutoff blade of roll forming machine is a key factor in ensuring clean cuts, long tool life, stable production performance, and low operating costs. At MTC Industrial, a professional roll former manufacturer based in Shanghai with over a decade of experience, we understand how blade materials influence production results across diverse roll forming applications — from roof & wall panel machines to purlin lines and guardrail roll forming machines.

In this guide, we explain the most commonly used cutoff blade materials in roll forming — including Cr12, Cr12MoV, SKD11, and DC53 steel — how to choose between them, and how they relate to specific machines you’ll find on our site.

Table of Contents

Why Cutoff Blade Material Matters in Roll Forming

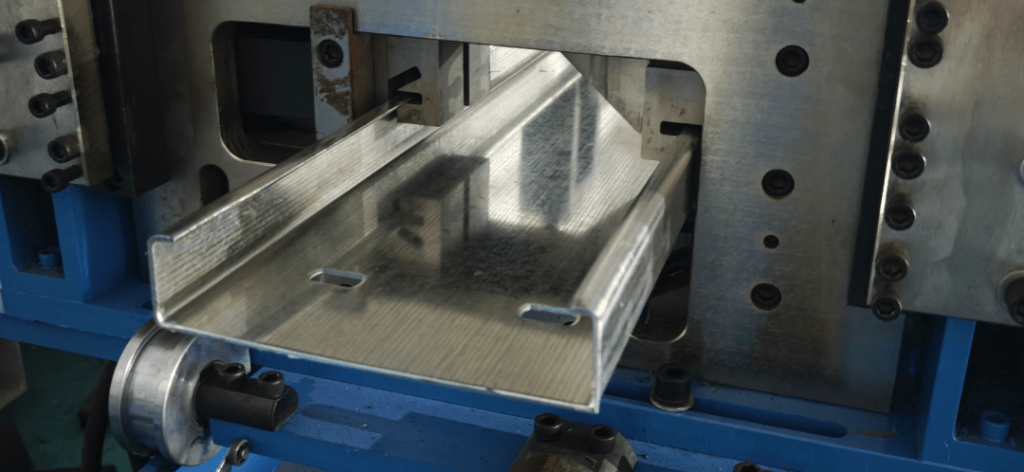

In a roll forming line, the hydarulic cutoff blade separates the finished profile from the continuous strip at precise lengths after the material has passed through forming rollers. Because this process subjects the blade to impact forces, friction, and heat, the material you choose for the blade directly affects:

- Cut quality and edge smoothness

- Precision and length accuracy

- Blade wear resistance and maintenance intervals

- Overall production efficiency and downtime

Using the wrong material can result in rough edges, frequent blade replacement, increased scrap rates, and unnecessary operating costs.

Overview of Common Cutoff Blade Materials

1. Cr12 Steel — Reliable Standard Choice

Cr12 steel is a high-carbon, high-chromium cold work tool steel widely used in roll forming cutoff blades.

Advantages:

- Good wear resistance after proper heat treatment

- High hardness and stable edge retention

- Cost-effective choice for general applications

Best for:

- Roofing & wall panel roll forming machines

- Metal floor deck machines

- Light duty fixed cutoff systems

Cr12 is suitable for applications where cutting frequency and impact loads are moderate. With adequate heat treatment, it can deliver consistent performance in general steel profile production lines.

2. Cr12MoV Steel — Improved Toughness for Frequent Cutting

Cr12MoV steel improves on Cr12 by adding molybdenum (Mo) and vanadium (V) to boost toughness and wear resistance.

Advantages:

- Better resistance to cracking and chipping

- Higher durability under repeated cutting loads

- Greater toughness compared to Cr12

Best for:

- C/Z steel purlin roll forming machines

- Solar strut channel roll forming machines

- Guardrail and crash barrier roll forming machines

Because these machines often run at higher speeds and operate under heavier impact, Cr12MoV blades offer improved life and less frequent maintenance.

3. SKD11 Steel — High Wear Resistance for Precision Cuts

SKD11 is a high-grade cold work tool steel (equivalent to D2) known for excellent edge retention and dimensional stability.

Advantages:

- Strong wear resistance

- Stable performance over long runs

- Suitable for tighter tolerance requirements

Best for:

- Stud & track roll forming machines

- Downpipe / rain gutter roll forming lines

- Customized profile machines where cut precision matters

SKD11 is ideal when the production demands higher cut accuracy and durability than what basic tool steel grades can provide.

4. DC53 Steel — Premium Performance for High-Speed Lines

DC53 is a premium cold work steel developed to combine high wear resistance with improved toughness.

Advantages:

- Excellent toughness and impact resistance

- Outstanding longevity in high-speed production

- Resistant to cracking under heavy loads

Best for:

- Flying cutoff roll forming machines

- High-speed purlin and solar channel lines

- Large structural profile roll forming machines

For automated, high-output production lines where downtime is costly, DC53 blades can significantly reduce maintenance frequency while ensuring consistent quality.

Matching Blade Material to Your Roll Forming Machines

MTC’s metal roll forming machine lineup includes a variety of heavy-duty and specialized equipment, and choosing the correct blade material ensures each machine performs optimally.

Below are key machine types and recommended cutoff materials:

Roofing & Wall Panel Machines

- Typical profile materials: pre-painted steel, aluminum

- Recommended blades: Cr12 for fixed cutoff, Cr12MoV for frequent cutting

C / Z Steel Purlin Machines

- High production speed and frequent profile changes

- Recommended blades: Cr12MoV and SKD11 for longer blade life

Heavy Duty Column Post Roll Formers

- Multiple shapes and precision cutting required

- Recommended blades: SKD11 or DC53 for high precision and durability

Guardrail / Crash Barrier Roll Forming Machines

- Heavy profile thickness, repeat cutting

- Recommended blades: Cr12MoV or DC53

Light Gauge & Door Component Machines

- Smaller sections with higher accuracy needs

- Recommended blades: SKD11 for precision, Cr12MoV for general production

Using the correct blade material for each application enhances machine performance, reduces blade change intervals, and improves overall line productivity.

Tips for Blade Heat Treatment & Maintenance

A steel’s inherent quality matters, but heat treatment and post-processing are equally critical. Metal roll forming machine cutoff blade hardness typically ranges between HRC 58–62 after proper tempering. Too soft and the blade wears rapidly; too hard and it becomes brittle.

Best practices include:

- Controlled vacuum heat treatment

- Uniform tempering to balance hardness and toughness

- Regular inspection for wear and micro-cracks

- Timely sharpening before severe damage

Maintaining blade health not only prolongs tool life, but also keeps your roll forming machines running at peak efficiency.

Cost vs. Performance — Making the Right Choice

Investing in premium materials like SKD11 and DC53 may involve higher initial costs, but the extended service life and reduced downtime often result in lower total cost of ownership for medium-to-high volume production lines. For budget-conscious operations, Cr12 and Cr12MoV provide a balanced combination of performance and value.

Choosing the right roll forming machine cutters is not just a technical detail — it’s a crucial decision that affects cut quality, production speed, tool life, and operating costs. At MTC Industrial Co., Ltd., our 10+ years of experience in designing and manufacturing metal roll forming machines — including C/Z purlin, roof & wall panel, floor decking, and solar channel lines — has taught us that matching the correct blade grade to your specific machine yields tangible benefits in performance and profitability. MTC RollForming Solutions

Whether you are considering Cr12, Cr12MoV, SKD11 or DC53 hydraulic cutoff blades for your next production upgrade, MTC’s team can help you select the right materials and configurations to optimize your roll forming process.

Keywords about the article

roll forming machine maintenance and blade selection

best cutoff blade materials for roll forming machine

Cr12MoV vs DC53 cutoff blade

roll forming machine blade material selection guide

SKD11 cutoff blade for purlin roll forming

cutoff blades for high-speed flying roll forming machines

metal roll forming machine blade wear resistance