Composite Floor Deck Roll Forming Machine – Roofing & Floor Deck Production Equipment

In the modern construction industry, speed, precision, and durability are the three pillars that determine the success of a building project. When it comes to structural flooring and roofing solutions, composite floor decking has become an essential component due to its strength, versatility, and ease of installation. At the heart of producing these high-performance decking sheets is the composite floor deck roll forming machine — an advanced piece of manufacturing technology designed to deliver quality, consistency, and efficiency.

Whether you call it a floor deck roll forming machine, a metal deck roll forming machine, a steel decking roll forming machine, or a roof deck roll forming machine, the principle remains the same: transforming steel coils into precisely formed decking profiles ready for structural applications.

Table of Contents

Understanding Composite Floor Decking

Composite floor decking refers to profiled steel sheets that work together with poured concrete to create a reinforced floor system. This system combines the tensile strength of steel and the compressive strength of concrete, producing a floor structure that is lighter, stronger, and more cost-effective than traditional reinforced concrete slabs.

Decking profiles are designed to serve as a permanent formwork during the concrete pour and as a tensile reinforcement after curing. The profile shape enhances the bond between steel and concrete, ensuring structural integrity.

Types of Formed Deck Profiles

One of the major advantages of using a steel decking roll forming machine is the ability to produce a wide variety of deck profiles, like B Deck, N Deck, 1.5″/2″/3″ composite floor deck and Losacero 25 Laminas floor deck etc. Here are some of the most common types:

1. B Deck

B Deck is a popular low-profile option (1.5″ deep) primarily used for roof decking or short-span flooring. It offers an excellent balance between weight and strength and is a common choice for commercial buildings.

2. N Deck

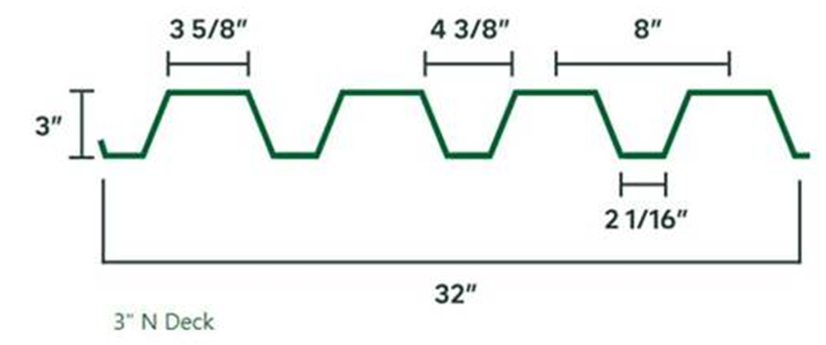

N Deck, with a profile depth of around 3″, is designed for long-span roof applications. Its deeper profile allows for greater load capacity and wider spacing between supports.

3. 1.5″ Composite Floor Deck

This deck type is used for short to medium-span composite floor systems. The shallow profile works well for floors requiring lower concrete volumes and quicker installation.

4. 2″ Composite Floor Deck

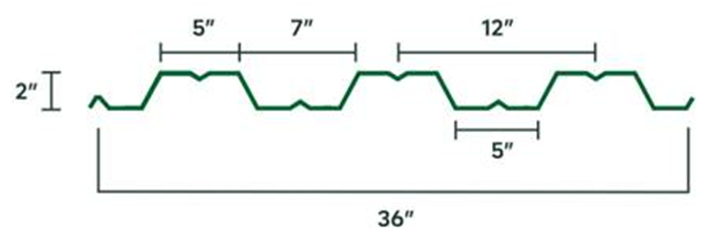

With its increased depth, the 2″ profile allows for longer spans and greater load-bearing capacity compared to the 1.5″ version, making it suitable for mid-rise buildings.

5. 3″ Composite Floor Deck

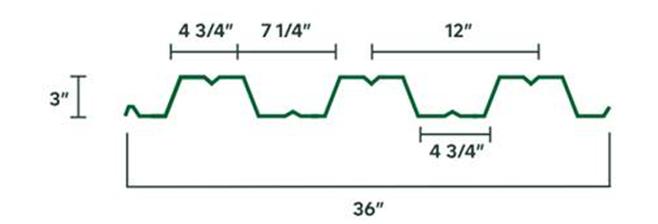

The 3″ profile is ideal for projects that require high strength and long spans, such as high-rise commercial towers or heavy industrial floors.

Applications of Metal Decking

The profiles produced by a metal deck roll forming machine are used in:

- Commercial office buildings

- Industrial warehouses

- High-rise residential towers

- Shopping malls

- Parking structures

- Bridges and walkways

Why Choose a Composite Floor Deck Roll Forming Machine?

A composite floor deck roll forming machine is designed to produce these profiles with precision and speed. Here’s why it’s the go-to choice for decking manufacturers:

1. High Precision Manufacturing

The roll forming process ensures that every deck profile meets strict dimensional tolerances. This precision translates into perfect alignment on-site, reducing installation time and errors.

2. Versatility

From B Deck to 3″ composite profiles, the machine can be customized with tooling sets to produce a wide range of profiles, meeting diverse project requirements.

3. Efficiency and Speed

Modern floor deck roll forming machines operate at high speeds, allowing manufacturers to meet tight project deadlines without compromising quality.

4. Durability

Constructed with high-grade steel frames and precision-machined rollers, these machines are built for long-term operation under continuous production conditions.

Steel Decking Roll Forming Machine Technical Parameters

While specifications can vary depending on the manufacturer and model, a typical steel decking roll forming machine has the following technical parameters:

| Specification | Details |

|---|---|

| Material | Galvanized Steel, Galvalume Steel, Cold Rolled Steel |

| Material Thickness | 0.8 – 1.5 mm |

| Profile Depths | 1.5″, 2″, 3″ (customizable) |

| Coil Width | 1000 – 1250 mm |

| Forming Speed | 10–20 m/min |

| Roller Stations | 24–46 stations |

| Roller Material | High-Grade Steel with Hard Chrome Plating |

| Drive System | Chain or Gear Drive |

| Cutting System | Hydraulic Cutting (Burr-Free) |

| Control System | PLC with Touchscreen Interface |

| Power Requirement | 380V / 50Hz / 3 Phase |

| Machine Size | 12m × 1.5m × 1.4m |

| Machine Weight | 10–12 Tons |

Roof Deck Roll Forming Machine

Interestingly, many roof deck roll forming machines are designed to produce both floor decking and roof decking by simply changing the tooling sets. This flexibility is valuable for manufacturers aiming to serve multiple markets without investing in separate production lines.

Advancements in Deck Roll Forming Technology

Recent innovations have made these machines smarter and more energy-efficient:

- Servo-Driven Feed Systems for accurate sheet positioning.

- Quick Change Tooling for faster profile switchovers.

- Remote Diagnostics for real-time troubleshooting and maintenance.

- Integrated Safety Systems to protect operators.

Metal Floor Decking Roll Forming Machine

The composite floor deck roll forming machine is an essential asset for any manufacturer in the construction materials sector. By producing B Deck, N Deck, and various composite profiles from 1.5″ to 3″, it meets a wide range of structural demands.

With advanced technology, high precision, and customizable configurations, these machines enable faster, more cost-effective, and higher-quality production of metal decking.

Whether you’re looking for a floor decking roll forming machine, a metal deck roll forming machine, a steel decking roll forming machine, or a roof deck roll forming machine, investing in a high-quality system will position your business for long-term success in the ever-demanding construction industry.

Furthermore, by integrating automation features such as programmable cutting lengths, profile changeover systems, and enhanced safety mechanisms, modern composite floor deck roll forming machines not only boost production efficiency but also reduce labor costs and operational downtime. This combination of versatility, durability, and smart manufacturing technology ensures your operation stays competitive and ready to meet future market demands.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of roll forming solutions, including various metal forming related equipment in China.

[…] total, the length of the whole composite floor deck roll forming machine line exceeds 30m, therefore it is necessary to disassemble the line for shipping. The decking panel […]