Bemo Panel Roll Forming Machine FAT Completed and Ready for Shipment

We are excited to announce something important. We have successfully completed the factory testing of a new Bemo Panel Roll Forming Machine. It is now ready for shipment. This advanced machine is designed to produce Bemo panels. Bemo roof panels are a type of high-quality roofing and siding material. They are widely recognized for their durability and aesthetic appeal. They are usually installed and seamed standing sides. Therefore, bemo panels are usually called standing seam roof panels as well. The Bemo panel roll forming machine is a significant addition to our range of roofing solutions. We are thrilled to share more details about this machine with our valued customers.

Table of Contents

What is the Bemo Panel Roll Forming Machine?

The Bemo Panel Roll Forming Machine is sometimes known as a standing seam roll forming machine. It is specifically engineered to create Bemo panels. These panels are primarily used for roofing and wall cladding applications. These panels are known for their sleek, modern look and superior performance. Our Standing seam roof roll forming machine can process pre-painted steel sheets. It can also handle aluminum sheets of various thicknesses.

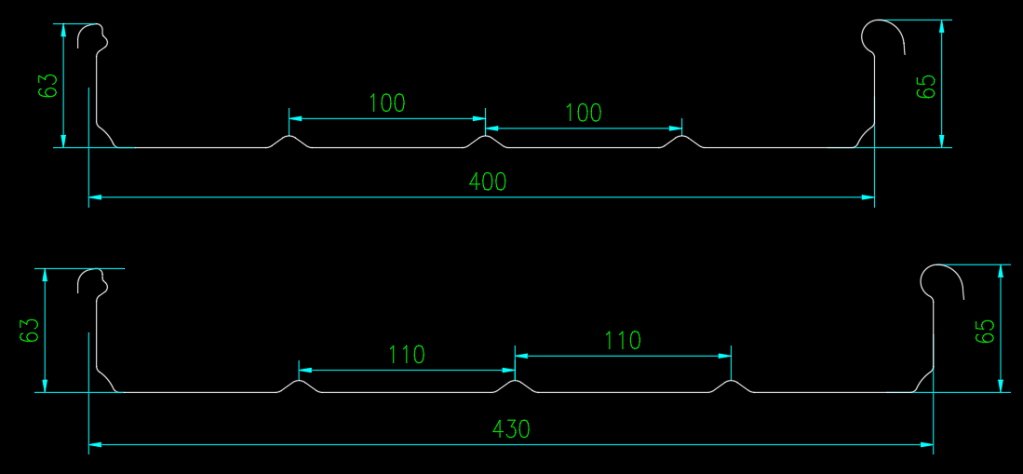

This bemo sheet roll forming machine has an impressive range of capabilities. It can produce Bemo panels or standing seam roof panels with widths of 400/430mm. The height is 65mm. It offers excellent flexibility for a variety of construction projects. The width is manually adjustable, allowing for tailored specifications to meet different requirements.

Machine Specifications and Features

The standing seam roof panel roll forming machine is designed with precision and efficiency in mind. Its main components include:

- Manual Decoiler: For loading and uncoiling metal sheets, ensuring smooth and controlled feeding into the machine.

- Roll Forming Machine: The core of the operation, this machine transforms the metal sheets into the desired Bemo panel profile. The roll forming process shapes the sheets into the distinctive standing seam profile of Bemo panels.

- Hydraulic Cutting System: Once the panels are formed, the hydraulic cutting system trims them to the required length. This process is completed with high accuracy and speed.

- PLC Control System: A PLC (Programmable Logic Controller) system controls the entire production process. It features an easy-to-use touch screen interface for seamless operation.

- Hydraulic Pump Station: This system powers the hydraulic components of the machine, including the cutting and forming mechanisms.

- Outfeed Table: After the panels are cut, they are moved to the outfeed table. Here, they are prepared for further processing or packaging.

This roll forming machine bemo standing can handle a wide range of materials, including pre-painted steel with a thickness of 0.5-0.8mm and aluminum sheets with a thickness of 0.7-1.2mm, making it versatile enough to meet different customer needs and specifications.

Key Advantages of the Standing Seam Roof Roll Forming Machine

The Bemo roofing roll forming machine offers numerous advantages for manufacturers and construction professionals alike:

- Flexibility in Material Options: You can work with pre-painted steel sheets. You can also use aluminum. This bemo roof panel roll forming machine can easily handle different types of materials. The machine’s ability to process materials with varying thicknesses (ranging from 0.5mm to 1.2mm) gives manufacturers the flexibility to cater to a wide array of client demands.

- Energy-Efficient and Easy to Operate: The PLC control system integrates effectively. It combines with an intuitive touch screen interface to simplify the machine’s operation. Operators can easily adjust settings such as material thickness, panel length, and cutting speed. Additionally, the PLC system optimizes energy consumption, ensuring that the machine runs efficiently with minimal waste.

- High-Speed Production: This standing seam roll forming machine is designed for high throughput. It features an efficient roll forming process. This process minimizes downtime and maximizes production speed. The automatic cut-to-length feature ensures that the Bemo panels are cut accurately and quickly, keeping production lines running smoothly.

Applications of Bemo Panels

Bemo panels are widely used in the construction industry for their superior performance and aesthetic appeal. These panels are particularly popular for:

- Roofing: Bemo panels offer exceptional weather resistance and are ideal for both commercial and residential roofing applications. The panels are designed to withstand harsh weather conditions, making them perfect for roofing in a variety of climates.

- Wall Cladding: In addition to roofing, Bemo panels are also used for wall cladding. They provide a sleek, modern look to building facades. The standing seam design of the panels ensures a secure, watertight fit, making them an excellent choice for exterior applications.

- Industrial Buildings: Bemo panels are often used in the construction of industrial buildings. Their durability and strength make them ideal for warehouses and storage facilities. The panels offer excellent insulation properties, which can help improve energy efficiency in these buildings.

The Installation and Delivery Process

After 75 days of meticulous design, our Bemo sheet roll forming machine is now complete. It is ready for shipment. The machine has undergone rigorous quality checks to ensure it meets the highest standards of performance and durability. We are proud to offer a product that is capable of delivering exceptional results for our clients.

We will be shipping the machine to its destination shortly. We look forward to hearing about the success of this machine in its new home. With this Bemo panel roll forming machine, our customers can produce high-quality Bemo panels. These panels will elevate their construction projects to new heights.

Conclusion

The Bemo panel roll forming machine is versatile and high-performance. It provides a solution for manufacturers looking to produce top-quality Bemo panels. These panels are suitable for a variety of applications. This machine is set to revolutionize the roofing and siding industry. It features advanced technology. The operation is easy. It can work with multiple materials. We are excited to see how this machine will benefit our customers. We are eager to support their success in the years to come.

For more information on the Bemo panel roll forming machine, please contact us today! To inquire about its capabilities and customization options, reach out to us.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.