Roll Forming Machine Shipped to the USA for PU Sandwich Panel Production

We are pleased to share that a new width adjustable metal forming machine has been successfully shipped from Shanghai Port to a valued customer in the United States. This customized line is designed for the precise production of the upper and lower metal facings of polyurethane (PU) sandwich panels, widely used in insulated wall and roof cladding systems across industrial, commercial, and residential buildings.

This project marks another milestone in our global outreach, and it further strengthens our position as a trusted manufacturer of PU sandwich panel roll forming machines and PU sandwich panel production line solutions.

Table of Contents

Designed for PU Insulated Panel Manufacturers

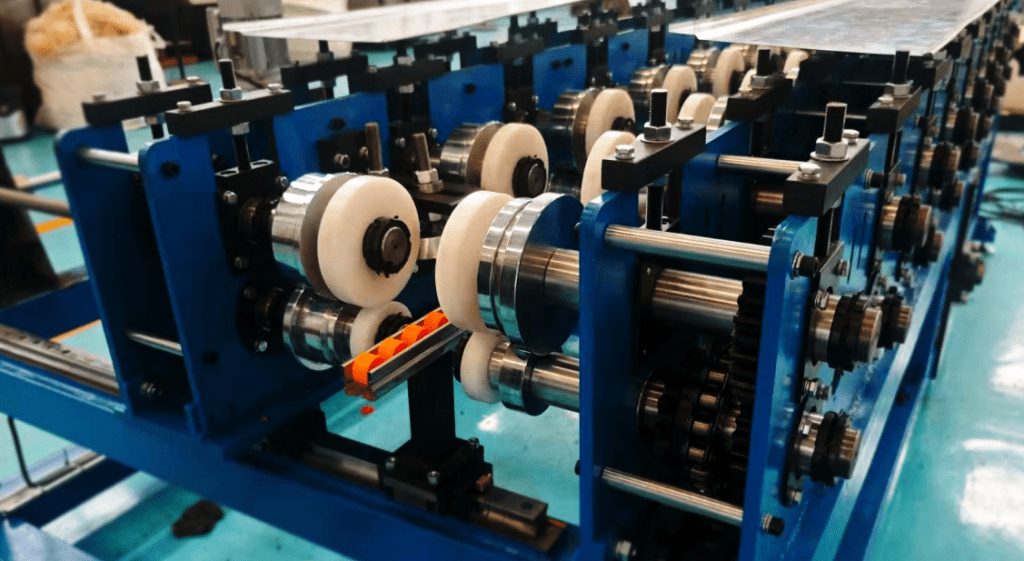

The shipped roll forming machine is engineered for PU sandwich panel manufacturers that require flexible production capabilities to meet diverse panel specifications. This model supports adjustable coil widths from 400 mm to 1200 mm (equivalent to 16 inches to 46 inches), making it suitable for manufacturing different sizes of PU insulated panels, including those produced by the width adjustable metal forming machine. It also handles a material thickness range of 0.8 mm to 1.2 mm (22 gauge to 18 gauge), which is ideal for both wall and roof panel applications.

Such flexibility in width and thickness allows manufacturers to respond more quickly to market demands and customized orders, minimizing downtime caused by equipment changes and increasing production efficiency.

To ensure compatibility with North American industrial power standards, a 100KVA transformer is included in the shipment. This transformer converts 480V to 380V, allowing seamless integration with the customer’s existing electrical infrastructure. The entire system is packed into a 20-foot container and shipped via Shanghai Port, ensuring fast and efficient delivery. This PU sandwich panel roll forming machine represents a highly practical and economical solution for manufacturers looking to expand their production lines with reliable, width-adjustable equipment.

– 100KVA transformer included for North American compatibility – Converts 480V to 380V for integration with existing infrastructure – Packed in a 20-foot container for shipping – Shipped via Shanghai Port for fast delivery – PU sandwich panel roll forming machine offers practical, economical solution – Reliable, width-adjustable equipment for production line expansion

Key Machine Specifications

To accommodate the customer’s production needs, the roll forming system includes the following technical highlights:

| Parameter | Specification |

|---|---|

| Working width range | 400–1200 mm (16″–46″) |

| Material thickness range | 0.8–1.2 mm (22–18 gauge) |

| Application | Top and bottom metal facings of PU panels |

| Drive system | Chain drive |

| Cutting system | Not included |

| PLC control | Not included |

| Control cabinet | Simple forward/reverse and side-shift panel |

| Power supply adaptation | 100 KVA transformer, 480V to 380V |

| Shipping | 1 × 20ft container from Shanghai Port |

This PU sandwich panel making machine is delivered without an integrated cutting system, as per the customer’s specific workflow setup. Instead, the customer will integrate a separate cutting system downstream in their production line. This width adjustable roll forming machine is also built without a PLC control system; instead, a simplified electrical control cabinet allows for manual operations such as advancing, reversing, and left/right movement.

Transformer Integration for Power Compatibility

Since the customer operates on a 480V industrial power standard, we provided a dedicated 100KVA transformer to convert the voltage from 480V to 380V. This transformer ensures seamless operation of the roll forming machine within their facility, without the need for additional on-site electrical modifications. This also minimizes installation time and reduces the risk of voltage mismatch issues during commissioning.

Our engineering team worked closely with the customer to ensure the transformer meets both safety and performance requirements, offering high reliability and stable output under continuous load.

Benefits of Width Adjustable Metal Roll Forming Machines

Width-adjustable metal forming machines offer several critical advantages for PU sandwich panel production:

- Flexible Production Range: One line can handle a wide range of panel sizes without requiring tooling changeovers.

- Inventory Efficiency: Manufacturers can reduce pre-cut steel inventory by using coil stock of varying widths as needed.

- Cost Reduction: Flexible width capability eliminates the need for multiple fixed-width lines.

- Market Responsiveness: Rapid response to custom-size orders and project-specific demands.

These features make our width adjustable roll forming machine especially suitable for PU insulated wall panel manufacturers seeking efficiency and adaptability.

PU sandwich panels typically consist of three layers: a metal top skin, a rigid polyurethane foam core, and a metal bottom skin. The quality of the outer skins directly affects the panel’s structural integrity, weather resistance, and insulation performance.

Our roll forming machine plays a crucial role in the production of these skins, ensuring:

- Consistent Thickness Tolerance

- Accurate Coil Feeding and Tracking

- Clean, Burr-Free Edges

- Smooth Surface Finish

When paired with a continuous PU foaming line, the top and bottom metal sheets are bonded to the foam core using high-pressure injection, forming a composite panel that delivers outstanding thermal insulation, fire resistance, and structural rigidity.

Efficient Packing and Delivery

The complete roll forming machine, including its components and 100KVA transformer, was securely packed and loaded into one 20-foot shipping container. Our logistics team ensured all parts were properly secured to avoid any damage during transit. The equipment departed from Shanghai Port and is scheduled to arrive at the customer’s U.S. facility in the coming weeks.

Our support team will assist remotely with the machine installation and provide technical documentation to ensure smooth setup.

Trusted Manufacturer of PU Sandwich Panel Making Machines

With years of experience serving global customers, we continue to focus on innovation, quality, and service. Our PU sandwich panel roll forming machines are trusted by clients in over 60 countries for their reliability and performance in high-volume production environments.

Whether you need a fully automatic PU sandwich panel production line or a semi-automatic solution with width flexibility, we can customize equipment to suit your project and budget.

Interested in flexible PU panel production solutions?

Get in touch with our technical sales team to request a quote or learn more about our width adjustable metal forming machines. We’re ready to help you build the next generation of insulated panel systems.

MTC supplies roll forming machines to a variety of applications including:

- Construction and building industry

- Automotive industry

- Appliance manufacturing industry

- Furniture industry

- Solar energy industry

- Material handling industry

- Infrastructure industry

- Electrical enclosures industry

- Rack & shelf industry

- and so on….

About MTC. – MTC. (“Make True Change”) has a history of quality and service dating back to 2009. Since its founding, the company has expanded its market to over 30 countries and is now one of the leading privately held suppliers of metal forming related equipment in China.

[…] panel types can be manufactured on the same PU sandwich panel roll forming machine, ensuring uniform quality and ease of […]