Shop » Cold Roll Former » Solar Channel Machines » Strut Channel Roll Forming Machine for Solar – Direct from MTC Factory

Strut Channel Roll Forming Machine for Solar – Direct from MTC Factory

Original price was: $78,000.00.$76,500.00Current price is: $76,500.00.

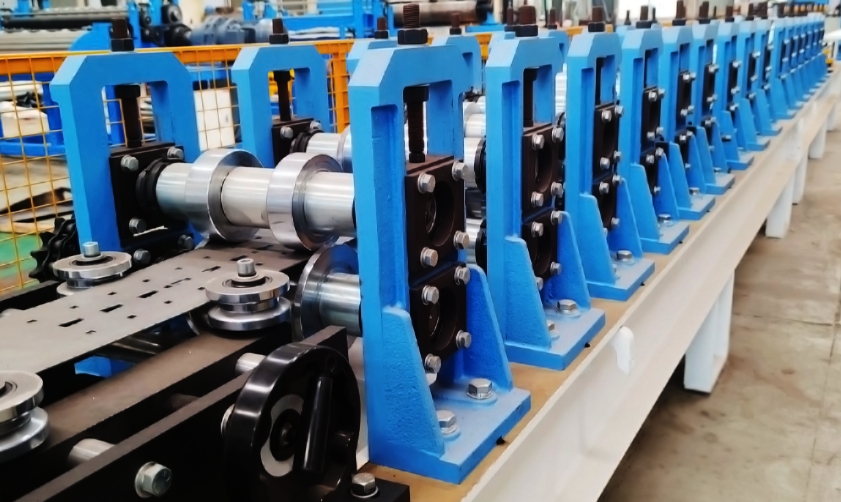

High-end strut channel roll forming machine for producing solar mounting framing channels with exceptional precision and durability. Gearbox-driven machine ideal for Unistrut channels 41×21 and 41×41, featuring cast-iron stands, integrated hydraulic tracking punching, and automatic cutoff. High-performance, automated, and precise.

We also offer C and U solar channel roll forming machines to meet diverse construction and solar mounting needs. Perfect for solar panel installation, construction projects, and customized framing solutions. Reliable, efficient, and easy to operate, with a 24-month warranty to ensure worry-free production.

26 in stock

Description

If you are looking to buy a strut channel roll forming machine for solar frames that combines precision engineering, durability, and high production efficiency, MTC Machinery offers the ideal solution.

What Are Strut Channels?

MTC proudly offers a state-of-the-art strut channel roll forming machines engineered to produce high-quality unistrut channel roll forming machine profiles, or Strut Channels. Strut channels, sometimes referred to as Unistrut channels, are standardized metal framing components used in a wide range of construction and industrial applications. They are typically formed from steel or aluminum into a C-shaped or U-shaped cross-section, with evenly spaced slots or holes along their length to allow easy attachment of fittings, clamps, and other hardware.

Because of their modular design and ease of assembly, strut channels are widely used for building support frames, cable trays, pipe hangers, ductwork supports, solar panel mounting systems, and other structural frameworks where flexibility and adjustability are key. Installers can cut strut channels to length on-site and assemble entire support structures without welding or drilling, using only standard brackets, bolts, and nuts.

Strut channels come in various profiles — such as plain, slotted, or with integrated grooves — and can be made from galvanized steel, stainless steel, or other coated materials to resist corrosion in harsh environments.

In modern manufacturing, these channels are produced efficiently and consistently using dedicated strut channel roll forming machines, which form flat coils of steel into precise channel profiles with inline punching, cutting, and slotting as required.

Strut Channel Roll Forming Machine: Your One-Stop Solution for Solar and Industrial Framing

Our strut channel roll forming machine is designed for continuous production of high-quality strut channels used in metal framing, solar mounting systems, cable management, and construction projects worldwide. It processes galvanized steel, stainless steel, or aluminum coils into accurately shaped C channels or strut channels with smooth edges and consistent dimensions.It is also called unistrut channel roll forming machine because it can produce unistrut channels invented by Aktore with 41*21, 41*41, 41*52, 41*62 and so on. These channels serve as the backbone for support structures in solar panel mounting, electrical cable management, pipe and duct hangers, and general industrial framing. Under different contexts, the same equipment is marketed as:

- Solar channel roll forming machine

- Solar mounting frame roll forming machine

- Solar panel mounting frame roll forming machine

- Solar panel structure roll forming machine

Our strut channel roll forming machine is built for heavy-duty operation. It processes galvanized steel, stainless steel, or aluminum coils into accurately shaped C channels or strut channels with smooth edges and consistent dimensions. Whether you need standard profiles or custom designs, MTC’s engineering team ensures each machine delivers exceptional forming accuracy and reliable performance.

The solar mounting frame roll forming machine is suitable for producing different sizes of strut channels with or without punching patterns, making it a versatile investment for manufacturers in multiple industries.

Types of Channels: C/U-Type, Standrad Type, and G-Type Profiles

1. C/U-Type Solar Channels

- Profile Description: Deep “C” section with long flanges and a pronounced web.

- Structural Benefits: Superior section modulus and load capacity per unit weight.

- Primary Uses: Main rails for ground-mounted and rooftop PV arrays; heavy-duty cable trays.

2. Standard Unistrut Channels

- Profile Description: Shallower “U” section with shorter flanges, optimized for lighter framing.

- Structural Benefits: Reduced material usage with adequate rigidity for secondary supports.

- Primary Uses: Cross-beams, secondary racking supports, solar tracker components.

3. G-Type Solar Mounting Channels

- Profile Description: Custom “G” geometry featuring integrated grooves or lips for snap-in fittings.

- Structural Benefits: Higher torsional stiffness and simplified hardware attachment.

- Primary Uses: Adjustable tilt-angle brackets, dynamic mounting systems, high wind/seismic regions.

Machine Configuration Options

A. Punching & Slotting Systems

| System Type | Advantages | Typical Speed |

|---|---|---|

| High-Speed Separate Press | Ultra-fast, high tonnage | 20–30 m/min |

| Tracking/Moveable Post Puncher | Continuous, cost-effective | 10–20 m/min |

| Separate Pre-Punch Unit | Multi-sided flexibility | 8–15 m/min |

| Stop-to-Punch System | Low initial cost | 5–8 m/min |

| Fly-Punch & Fly-Cut | Combined operation, minimal downtime | 10–25 m/min |

- High-Speed Separate Press: Positioned before forming for large batch runs.

- Tracking/Moveable Puncher: Bottom-only punching without stopping the line.

- Pre-Punch Unit: Holes on flanges and web prior to final forming.

- Stop-to-Punch: Line halts at each station, then resumes.

- Fly-Punch & Fly-Cut: Synchronized punching and trimming in one module.

B. Frame & Stand Construction

- Welded Steel-Plate Frame: Cost-effective, rapid fabrication; moderate rigidity.

- Cast-Iron Frame: Superior damping and precision; ideal for high-speed.

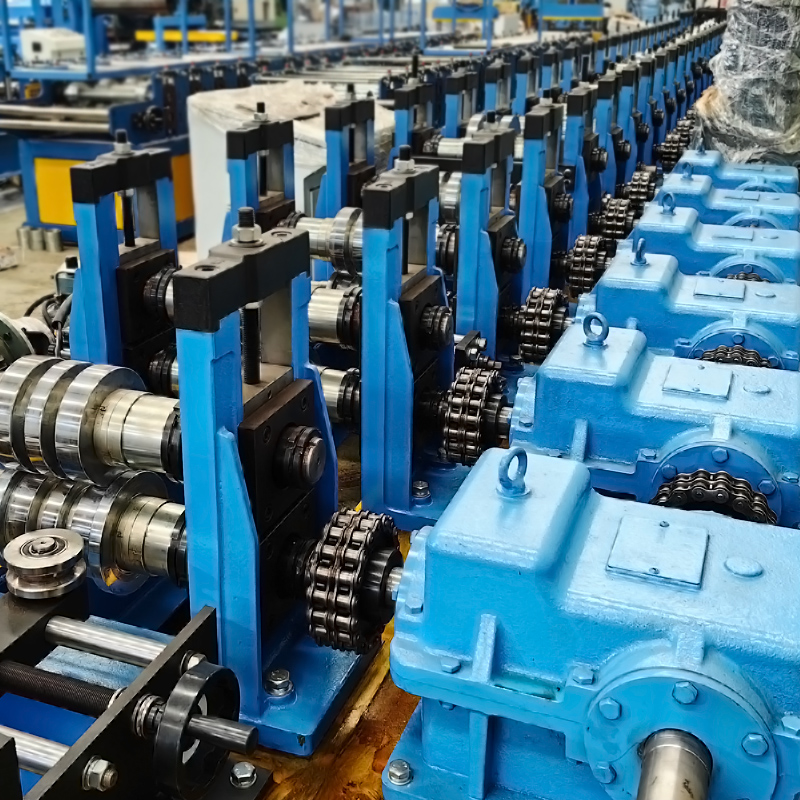

C. Transmission Systems

- Chain & Sprocket Transmission: Easy maintenance; periodic tensioning.

- Gearbox Transmission: High torque, low backlash; higher cost.

D. Cut-Off Solutions

- Stop-to-Cut Shear: Clean 90° cuts; up to ~10 m/min.

- Flying Shear: On-the-fly cutting; up to ~25 m/min.

Technical Parameters

| Parameter | Specification |

|---|---|

| Raw Material Width | 90–180 mm |

| Material Thickness | 1.5–2.5 mm |

| Forming Stations | 24 rolls |

| Roller Material | GCr15 bearing steel, heat-treated |

| Main Shaft Diameter | Φ80 mm, quenched & ground |

| Line Speed | 10–20 m/min (depending on config) |

| Punching Capacity | 110 TONS |

| Punching Frequency | Up to 120 p/min |

| Cutting Method | Stop-to-cut shear or flying shear |

| Drive System | Chain & sprocket or gearbox |

| Decoiler Capacity | 3 T load |

| Hydraulic Power Unit | 5.5 kW (cutting) |

| Electrical Control | PLC with HMI |

| Total Power Consumption | ≈35 kW |

| Dimensions (L×W×H) | 25m × 1.4 × 1.5 m |

| Machine Weight | 8-10 T |

| Tolerance | ±0.1 mm |

| Frame Type | Welded plate / Cast iron (optional) |

| Transmission | Chain & sprocket / Gearbox (optional) |

Key Features & Advantages

- Precision Forming: Each station of our unistrut channel roll forming machine is designed with high-grade rollers and precise alignment to ensure dimensional accuracy and minimize material deformation.

- Integrated Punching System: The solar panel structure roll forming machine can punch various hole patterns in a single cycle, reducing the need for secondary processing and increasing efficiency.

- Heavy-Duty Structure: Built with a rigid steel frame, this solar mounting frame roll forming machine is capable of long-term operation under heavy workloads without compromising performance.

- Easy Operation & Automation: The Siemens PLC system allows operators to set production lengths and quantities in advance. Automatic measuring and cutting minimize waste and improve consistency.

Production Process

- Material Loading – The hydraulic decoiler holds and feeds the steel coil.

- Leveling – The material passes through a leveling unit to remove coil set.

- Punching – Hydraulic punching unit creates holes according to preset patterns.

- Roll Forming – The strip is shaped gradually through multiple roll forming stations.

- Cutting – The formed channel is cut to length by hydraulic or flying shear cutting.

- Collection – Finished products are stacked and ready for packaging or direct shipment.

Learn more about the working process in our Strut Channel Roll Forming Machine Guide.

Applications

- Solar Mounting Frames – For photovoltaic panel support systems

- Electrical & Mechanical Support – Cable trays, conduit supports, and pipe racks

- Industrial Racking Systems – Shelving, storage, and warehouse systems

- Construction Projects – Ceiling grids, framing, and partition walls

Why Choose MTC Machinery?

With over a decade of experience in roll forming technology, MTC Machinery has supplied equipment to customers in more than 60 countries. Our machines are known for their robust design, advanced automation, and low maintenance requirements. From the first inquiry to after-sales support, we provide complete solutions to ensure your investment delivers long-term value.

FAQ

Q1: What materials can this machine process?

A1: Mostly a strut channel making machine handles with Galvanized steel and stainless steel. If you have special requirment, we may make a customized proposal.

Q2: Can I produce multiple channel sizes with one machine?

A2: Yes, we can design a 2-in-1 roll forming systems for producing different profiles. See more at Double Row Roll Forming Machine.

Q3: How fast can this strut channel making machine produce?

A3: Standard speed is 0–15 m/min, but high-speed options are available and max.speed can reach upto 40m/min.

Q4: Do you provide installation service?

A4: Yes, MTC provides on-site installation and operator training worldwide.

Q5: What is the warranty period?

A5: All machines come with a 24-month warranty and lifetime technical support.

Order Your Strut Channel Roll Forming Machine Today

If you are ready to invest in a reliable strut channel roll forming machine for sale, contact MTC Machinery today. We offer factory-direct pricing, customizable designs, and complete technical support to help you maximize production efficiency.

Additional information

| Weight | 8000 kg |

|---|---|

| Dimensions | 15000 × 800 × 1400 mm |

MAXON® –

High-precision unistrut channel roll forming machine for the solar mounting frames manufacturing. Durable, fast, and compatible with a high speed punching machine for slots.