Shop » Sandwich Panel Line » Continuous PU Sandwich Panel Production Line – 500 Aluminum Roof

Continuous PU Sandwich Panel Production Line – 500 Aluminum Roof

Original price was: $320,000.00.$315,000.00Current price is: $315,000.00.

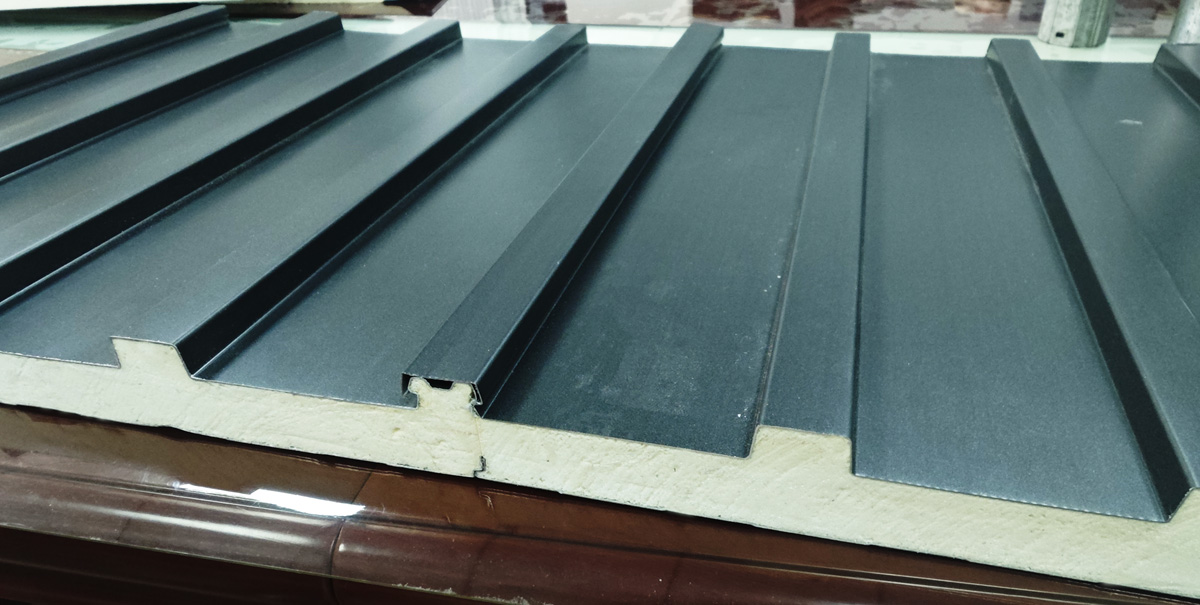

This Polyurethane (PU) foam sandwich panel production line was built to automatically and continuously manufacture 500 Aluminum roof sandwich panels with thickness 45-95mm variable.

Description

Our Aluminum PU Roof Sandwich Panel Production Line is a state-of-the-art PU / PIR Continuous Sandwich Panel Production Line designed specifically for the high-efficiency manufacturing of aluminum-faced polyurethane insulated panels. This continuous PU sandwich panel production line features rubber-belt lamination technology, ensuring precise panel thickness, strong adhesion, and a superior surface finish. The line is engineered to meet the growing demand for lightweight, high-performance roofing materials for modern construction, including sunny houses, tiny homes, and modular buildings.

Key Features:

- Continuous Production Process: Our system operates as a rubber-belt continuous sandwich panel production line, enabling uninterrupted panel formation and curing. This design increases productivity and reduces waste, making it ideal for large-scale manufacturing.

- Rubber-Belt Lamination System: Equipped with a precision rubber-belt PU sandwich panel production line setup, the panels undergo uniform compression, ensuring a smooth surface and consistent core bonding. This lamination method is perfect for maintaining panel quality across variable thicknesses.

- Panel Specifications:

- Effective Panel Width: 500mm

- Panel Thickness Range: 45mm to 95mm

- Face Material: 0.4-0.6mm aluminum sheets (top and bottom)

- Core Material: High-rigid polyurethane (PU) foam

- Interlocking Joint System: Panels are produced with an interlocking joint system that allows for secure connections without visible screws or bolts, offering a sleek and seamless appearance.

- Corrosion-Resistant Aluminum: The aluminum face sheets provide exceptional corrosion resistance, making the panels ideal for outdoor use. With proper installation and minimal maintenance, the panels have a service life of 30–40 years.

- Precision Control System: Advanced automation and user-friendly interface allow for real-time monitoring and adjustments, enhancing production flexibility and minimizing downtime.

Applications:

The panels produced by this Polyurethane sandwich panel line are widely used for roofing applications that demand excellent thermal insulation, weather resistance, and lightweight structure. Ideal uses include:

- Sunny Houses: Offers superior insulation and reflects solar radiation, maintaining indoor comfort in high-sunlight environments.

- Tiny Houses: Provides compact, durable roofing with excellent thermal efficiency and minimal structural load.

- Modular Houses: Enables fast, efficient installation and ensures structural integrity in prefabricated housing solutions.

These properties make the aluminum PU sandwich panel a preferred choice for modern green construction and energy-saving architectural designs.

Components of the Production Line:

Our Rubber Belt sandwich panel production line includes the following core equipment:

- Double-Head Decoiler: Feeds the aluminum coils into the system smoothly and efficiently.

- Roll Forming Machines: Shapes the aluminum sheets into precise roof panel profiles.

- Preheating Station: Ensures optimal adhesion by warming aluminum sheets before foaming.

- PU High-Pressure Foaming System: Injects PU foam with high precision to create a consistent and rigid core.

- Rubber-Belt Double Conveyor Laminator: Maintains pressure and alignment during the curing process, ensuring the highest product quality.

- Cross Cutting System: Accurately cuts panels to customized lengths without damaging the structure.

- Stacking and Packing System (Optional): Automatically stacks and wraps finished panels for easy handling and transportation.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Panel Width | 500mm (effective) |

| Panel Thickness Range | 45mm – 95mm |

| Panel Core Material | High-rigid Polyurethane (PU) |

| Panel Face Material | Aluminum sheets (0.4mm – 0.6mm) |

| Working Speed | 0 – 10 meters/min (adjustable) |

| PU Foaming Density | 40 – 45 kg/m³ |

| Laminating Conveyor Length | 26.5 meters (customizable) |

| Temperature Control | Automatic heating system |

| Cutting Accuracy | ±2mm |

| Total Installed Power | Approx. 100 – 120 kW |

| Line Dimensions (L×W×H) | Approx. 70m × 6m × 4.5m |

| Operation Mode | PLC + HMI (Touch Screen Interface) |

Advantages of the Aluminum PU Roof Panel Line:

- Superior Panel Quality: The combination of rubber-belt lamination and aluminum facing ensures a lightweight yet durable panel with excellent dimensional accuracy and surface finish.

- Energy Efficiency: Panels offer excellent thermal insulation, reducing energy consumption in heating and cooling.

- Invisible Fastening System: Thanks to the interlocking joint system, panels can be installed without visible screws or bolts, ensuring a clean, modern look.

- Low Maintenance: Aluminum facing provides corrosion resistance and weather durability, extending the panel’s service life to 30–40 years.

- High Rigidity Core: The PU foam used offers improved compressive strength and structural support.

- Environmentally Friendly: The production line minimizes waste and supports sustainable construction practices.

Why Choose Our PU Sandwich Panel Production Line?

- Customized Design: We tailor the Polyurethane sandwich panel line to your specific production needs and panel specifications.

- Turnkey Solutions: From design to installation and training, we offer full project support.

- Reliable After-Sales Service: Our experienced technical team ensures smooth operation and quick maintenance support worldwide.

- Proven Performance: Our lines are running successfully in several countries, trusted by manufacturers in prefab housing, construction materials, and more.

Technical Support & Training

Our team provides full technical support, including:

- Equipment installation and commissioning

- Operator training

- Maintenance guidance

- Remote diagnostics and software updates

We are committed to ensuring our clients achieve maximum efficiency and return on investment.

Additional information

| Weight | 66000 kg |

|---|---|

| Optional | Hydraulic Decoiler, Auto Stacker, Auto Packing, 30m Laminator |

| Installation & Commissioning | Available |

| Weight | 30 TONS |

| Dimension | 70m*6m*5m (L*W*H) |

Reviews

There are no reviews yet.