Shop » Cold Roll Former » Steel Purlin Machines » C Purlin Roll Forming Machine

C Purlin Roll Forming Machine

Original price was: $25,000.00.$23,800.00Current price is: $23,800.00.

Discover the best C Purlin Roll Forming Machine with 5 proven benefits: high precision, fast production, adjustable sizes, reliable performance, and affordable price. Get a quote today!

38 in stock

Description

What is a C Purlin Roll Forming Machine?

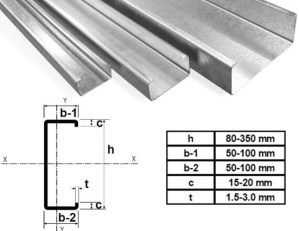

A C Purlin Roll Forming Machine is specialized industrial equipment that produces structural C-shaped steel purlins through a continuous cold-forming process. By passing steel strips through a precisely engineered series of rollers, the machine bends the material step by step to form an accurate C profile.

C purlins are a critical component in modern steel buildings, serving as roof purlins, wall girts, and floor joists. They are valued for their lightweight, high strength, and cost-effectiveness compared to traditional steel beams or timber supports.

Our C Purlin Roll Forming Machine delivers unparalleled accuracy, adjustable sizes, and efficient production speeds to meet the diverse needs of steel building contractors and manufacturers.

Why Choose Our C Purlin Roll Forming Machine?

✅ Precision You Can Rely On

We use advanced CNC-machined roller dies and a robust machine base to achieve consistent, high-quality forming. Even at high production speeds, the profiles meet stringent dimensional tolerances and surface finish standards.

✅ Flexible & Adjustable Sizes

Our machine allows for quick adjustment to produce C purlins with different web heights, flange widths, and lip sizes. Whether manual or fully automatic adjustment, you can quickly switch between sizes to handle different project requirements.

✅ Efficient Production Speeds

With a typical forming speed of 10–15 m/min and options for even higher speeds, our machine helps maximize throughput without compromising quality.

✅ Durable & Long-Lasting Components

The forming rollers are made from hardened, chrome-coated steel to resist wear. The frame is constructed from heavy-duty welded steel to minimize vibration and ensure stability during long production runs.

✅ Cost-Effective Solution

Compared to traditional bending or punching methods, roll forming significantly reduces labor costs, material waste, and processing time—resulting in a faster return on investment.

Key Technical Specifications

| Parameter | Details |

|---|---|

| Material | Galvanized Steel, Cold-Rolled Steel, etc. |

| Material Thickness | 1.5–3.0 mm (customizable) |

| Web Height Range | 80–300 mm |

| Flange Width Range | 30–100 mm |

| Lip Size | 10–20 mm |

| Production Speed | 10–15 m/min |

| Roller Stations | 13–20 |

| Main Motor Power | 11–22 kW |

| Transmission | Chain-gears OR Gear-boxes |

| Cutting System | Hydraulic or Flying Shear |

| Control System | PLC Automatic Control |

| Voltage | 380V/50Hz/3Phase (or customized) |

Need a specific configuration? Send us your profile drawing—we customize machines for your exact needs!

Applications of C Purlins Produced by Our Machine

The C purlins you produce with this machine can be used in a wide range of construction scenarios:

The C purlins you produce with this machine can be used in a wide range of construction scenarios:

- Roofing purlins and wall girts in industrial warehouses

- Mezzanine floors and bridging systems

- Canopies, carports, and parking shelters

- Pre-engineered steel buildings (PEBs)

- Agricultural and greenhouse structures

Their lightweight yet strong nature makes them perfect for modern, large-span steel buildings.

How Our Machine Works

The forming process begins when you load a coil of steel into the uncoiler. The sheet passes through a leveling system, then enters the forming rollers. At each forming station, the rollers gradually bend the sheet until it reaches the desired C-shaped profile. Finally, a hydraulic or flying shear cuts the purlin to the specified length without stopping the line, ensuring continuous, efficient production.

C Purlin vs. Other Purlin Options

Why choose C purlins over Z or U purlins?

- C purlins are ideal for shorter spans and simple roof designs.

- Easy to install and handle due to their lighter weight.

- Cost-effective for medium to large-scale projects.

- Compatible with most steel cladding and roofing systems.

If you also need Z purlins, check out our Quick-change CZ Purlin Roll Forming Machine, which can produce both profiles with minimal setup time.

After-Sales Support & Service

We stand behind every machine we sell:

- Warranty: 24 months for mechanical and electrical components.

- Spare Parts: Free during warranty period (excluding wear parts), available long-term at factory prices.

- Installation & Training: On-site service and operator training or remote support via video calls and manuals.

- Technical Support: Lifetime assistance from our expert engineers.

Your production success is our priority.

Frequently Asked Questions About C Purlin Machines

How long is the delivery time?

Typically 45–60 working days after receiving your order and deposit. For urgent orders, we may offer faster turnaround.

Can you customize the machine?

Yes! We tailor every machine to your specific profile drawings and production needs.

What power supply does it require?

Standard 380V/50Hz/3Phase. Other voltages/frequencies are available on request.

Do you offer operator training?

Yes, we provide full training to ensure your staff can operate and maintain the machine confidently.

More questions, please visit our page https://mtc-china.com/faqs/

Get Your Quote Today!

Ready to boost your production with our C Purlin Roll Forming Machine? Contact us now for a competitive quote and personalized consultation. Discover how our high-quality machines can help your business thrive.

Additional information

| Weight | 9500 kg |

|---|---|

| Dimensions | 9800 × 1200 × 1400 mm |

| Decoiler Optional | Manual or Hydrualic |

| Punching | Pre-punching or Post-punching |

| Control System | Panasonic/Siemens PLC Control, Yaskawa Inverter, Omron Encoder, MCGS HMI |

Reviews

There are no reviews yet.