A Turn-Key Solution For Metal Roll Forming Equipment At Best Prices!

Meet a roll forming machine manufacturer in Shanghai China -MTC Industrial Co., LTD. Here, we are committing to supply turn-key solutions for metal roll forming equipment and insulated sandwich panel production lines!

At present, MTC keeps on now in a 6000 square meters workshop with 38 employees and a 5-engineer team to crack down on the advancement of roll forming machine, and sandwich panel production lines. The company was set up in the year 2012. As well, MTC produces some support machines as accessory machine to our foremost merchandises. This includes sales consultancy, metal roll forming equipment designing, and building, to installation, training and maintaining service.

Table of Contents

Understanding Metal Roll Forming Equipment

In the realm of industrial fabrication, precision, efficiency, and versatility stand as paramount virtues. Metal roll forming equipment emerges as the unsung hero, revolutionizing the way metal sheets are shaped and fabricated. Its significance permeates various industries, from construction to automotive and beyond, owing to its ability to craft complex and customized metal profiles with unparalleled accuracy.

Plus, our glazed tile roll forming machine usually is always our first choice as long as we need to produce metal sheet or steel section products. A roll machine machine can do automatic jobs of bending, cutting, pressing for holes and slots, and straightening etc. Roll forming machines have so many advantages over press brake and shearing machines! With roll forming equipment, we can save much more time, working area, money as well as labors.

We at MTC fabricate cold roll former machine that is a process for shaping metal into convention range profile. These cold roll forming is flexible and gainful practice which is used across an extensive range of industries to manufacture parts. It is used in from metal forming in automobiles to appliances, airplanes and houses. The process offers a host of benefits and advantages over alternative approaches as well.

Being perfect for making invariable parts with stretched out lengths and enormous quantities, cold roll former is chosen by all the designers as it involves the chronic change direction of a prolonged strip of the sheet metal into a number one range. You can advantage high-end roll forming machine for both neighboring and foreign country markets.

Production skills is the most important factor in running an industry and one need to keep on growing in the business as long as the investments are concerned. The roll forming machine at MTC is manufactured using advanced quality materials and considering our customers business needs.

Precision Engineering

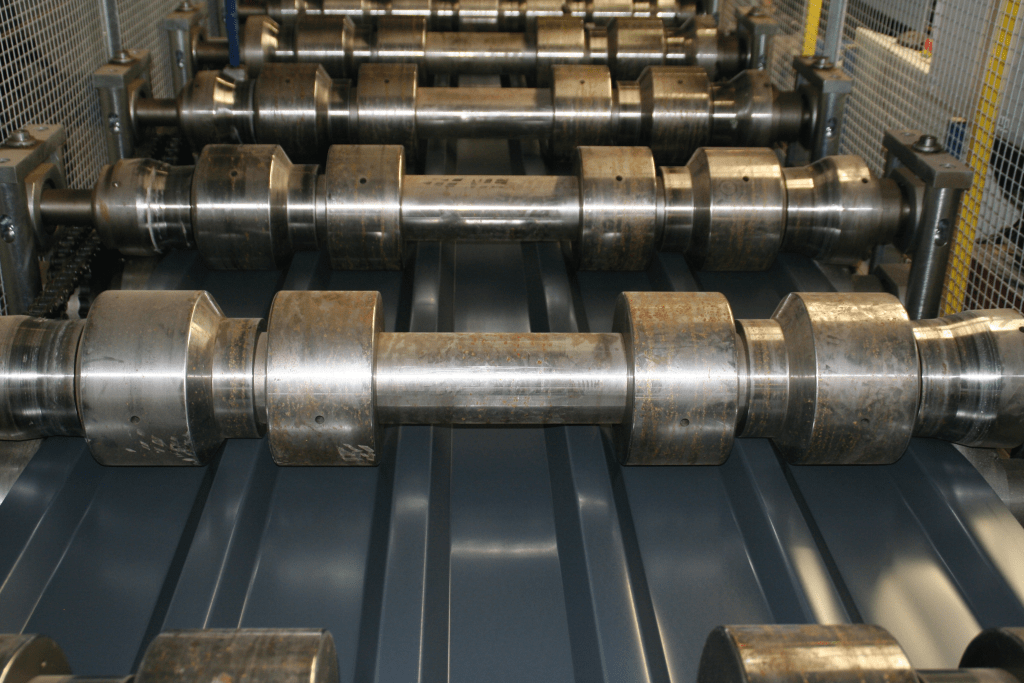

At its core, metal roll forming equipment operates through a continuous bending process, transforming metal coils into desired shapes and profiles. This process involves a series of synchronized rollers, meticulously designed to incrementally shape the metal as it passes through. The precision of these rollers ensures uniformity and consistency, even with intricate designs or complex geometries.

Versatility in Design

One of the prime advantages of metal roll forming equipment lies in its adaptability to diverse design needs. Whether it’s corrugated panels, tubes, channels, or angles, this equipment accommodates an extensive array of shapes and sizes. This versatility allows for the creation of tailored solutions, meeting specific industry requirements and enabling innovation in product design.

Efficiency and Cost-Effectiveness

Efficiency remains a cornerstone attribute of metal roll forming. The continuous, high-speed production capabilities significantly reduce manufacturing time compared to traditional fabrication methods. Moreover, the minimal material wastage inherent in this process enhances cost-effectiveness, making it an economically viable choice for large-scale production.

Applications Across Industries

Construction Sector

In the construction domain, metal roll forming equipment plays a pivotal role in shaping structural components such as roof panels, wall claddings, and framing elements. Its ability to produce long, uniform sections with precise dimensions proves invaluable in creating durable and aesthetically pleasing building materials.

Automotive and Transportation

In the automotive and transportation sectors, the demand for lightweight yet sturdy components is met through roll-formed parts. From chassis components to trim elements, the versatility of metal roll forming equipment fulfills the industry’s need for both strength and weight efficiency, contributing to enhanced vehicle performance.

Renewable Energy and Beyond

Additionally, the equipment finds application in renewable energy sectors, fabricating components for solar panel frames, wind turbine structures, and more. Its adaptability to various metals, including aluminum and stainless steel, makes it an ideal choice for industries requiring corrosion resistance and structural integrity.