Length Inaccuracy in Roll Forming Machines — Causes and Solutions

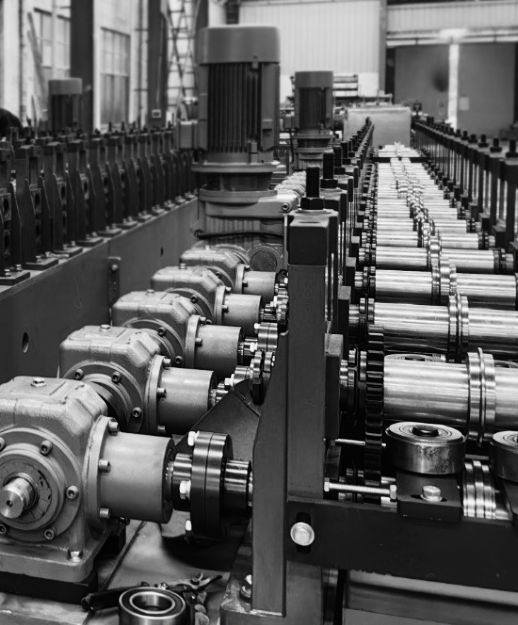

Precise cutting length is one of the key performance indicators of any roll forming line. Whether producing C/Z purlins, roofing sheets, floor decks, or sandwich panels, even a few millimeters of deviation per sheet can result in large cumulative waste, assembly issues, or rework. Despite different machine configurations, length inaccuracy in roll forming machines is one of the most common troubleshooting challenges faced across various roll forming systems.

Below we discuss the main causes of inaccurate cutting length and how they appear in different types of roll forming machines, along with practical solutions for each case.

Commono Issues & Solutions for the Length Inaccuracy During Roll Forming.

Table of Contents

1. Encoder Slippage or Improper Mounting

Machines affected: Roof panel roll forming machine, metal floor deck roll forming machine, PU sandwich panel line

Problem:

In most automatic roll forming lines, the encoder measures the sheet’s moving distance to trigger the cut at the set length. If the encoder wheel slips against the sheet or the mounting bracket vibrates during operation, the encoder will send inaccurate pulses, leading to inconsistent cut lengths — sometimes too long, sometimes too short.

Typical causes:

- Encoder wheel not pressed tightly on the sheet

- Accumulated oil or dust on the encoder surface

- Misalignment between encoder axis and feeding direction

- Loose or vibrating bracket

Solutions:

- Use a spring-loaded encoder arm to ensure consistent contact pressure.

- Clean the encoder wheel regularly, especially when running oily galvanized or aluminum sheets.

- Tighten or reinforce the encoder mounting bracket.

- For long-term reliability, install the encoder directly on the main drive roller instead of the sheet surface, minimizing slip errors.

2. Speed Variation or Inconsistent Deceleration Before Cutting

Machines affected: Steel purlin roll forming machine, roof tile line, and automatic high-speed panel line

Problem:

In many high-speed roll forming systems, the machine does not stop completely before cutting — it cuts on the fly. Inaccurate synchronization between roll forming speed, hydraulic shear movement, and PLC timing often leads to overlength or underlength problems, especially when the line accelerates or decelerates.

Typical causes:

- Incorrect deceleration delay (stop delay time) setting

- Slow hydraulic valve response

- PLC scan cycle too long or incorrect timing calibration

- Excessive inertia in the drive motor causing the material to overrun after stop signal

Solutions:

- Recalibrate the “stop delay” or “cut delay” time according to the actual deceleration curve.

- Adjust the hydraulic shear speed and ensure the solenoid valve is fast enough for on-the-fly cutting.

- Use a servo motor system for better motion synchronization when cutting at high speeds.

- Add a test mode in PLC to simulate multiple length settings and measure deviation at different speeds.

3. Material Slippage During Feeding

Machines affected: Door frame roll forming machine, drywall stud track roll forming machine line, C-channel line

Problem:

When the sheet feeding is not stable — due to worn rollers, insufficient pressure, or improper alignment — the sheet may slip slightly during forming. This makes the encoder count more distance than the actual sheet movement, resulting in shorter product lengths.

Typical causes:

- Entrance guide rollers not aligned or too loose

- Drive rollers contaminated with oil or dust

- Material surface too smooth (e.g., color-coated aluminum)

- Insufficient roll forming pressure or too few drive stations

Solutions:

- Realign the entrance guide and tighten the lower pinch rollers.

- Increase the pressure on the first few drive rollers to improve feeding stability.

- For very smooth sheets, apply an anti-slip rubber layer on the encoder wheel or drive rollers.

- Inspect gearboxes and chains for backlash that may affect steady movement.

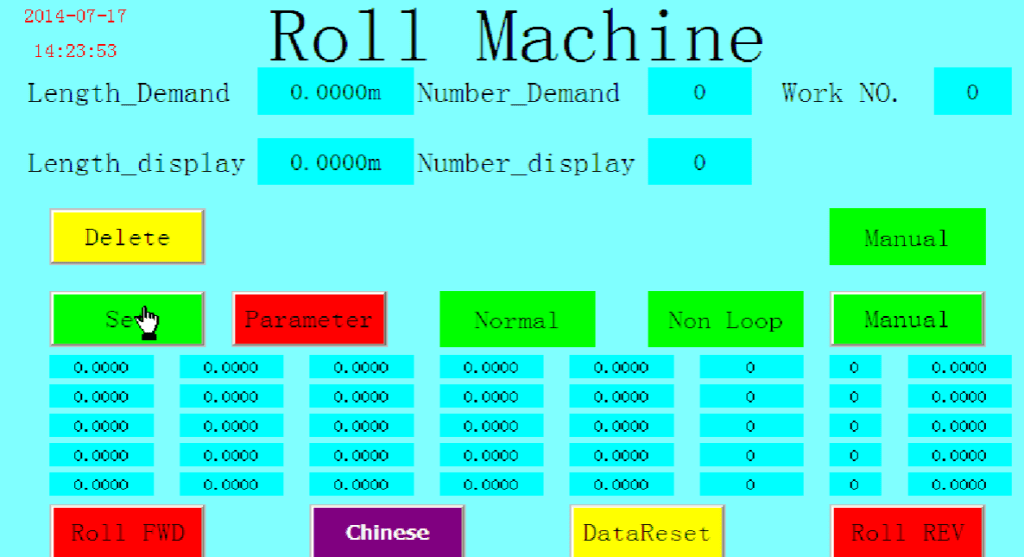

4. Incorrect Length Calibration in PLC or HMI

Machines affected: All roll forming machines like decking roll forming machine, c/z purlin roll forming machine with automatic control system

Problem:

Even when all mechanical components work properly, the length deviation may still exist if the PLC length coefficient (the number of encoder pulses per millimeter) is incorrect. This usually happens after encoder replacement, PLC software updates, or roller diameter changes.

Typical causes:

- Wrong scaling factor entered in HMI

- Encoder resolution (pulses/rev) differs from original setup

- PLC value rounding errors or integer limits in code

Solutions:

- Perform an actual measurement: feed 1 m manually and record the encoder pulse count to verify scaling.

- Update the “Length Coefficient” parameter in HMI accordingly.

- In advanced control systems, use floating-point arithmetic instead of integer-based calculation to improve precision.

- After recalibration, test multiple target lengths (e.g., 1000 mm, 3000 mm, 6000 mm) to confirm linear accuracy.

5. External Factors: Temperature and Material Coil Tension

Machines affected: PU sandwich panel lines and long roof panel lines

Problem:

Thermal expansion or excessive tension from the uncoiler can subtly stretch or shrink the material, especially when producing panels over 10 m long. The measured encoder length no longer represents the actual physical size after release.

Solutions:

- Maintain stable room temperature during production.

- Adjust uncoiler brake tension to a moderate level — not too tight to stretch the sheet.

- Allow long panels to rest after cutting before measuring for final inspection.

Final Checkpoints for Consistent Cutting Accuracy

To keep the machine running within ±1 mm accuracy range, operators should include the following in daily maintenance routines:

- Check encoder and hydraulic system response weekly.

- Clean rollers and encoder wheels daily.

- Verify PLC delay timing after each production speed change.

- Test one standard piece at shift start to confirm cutting accuracy.

Length Inaccuracy in Roll Forming Machines

Length inaccuracy may seem like a small issue, but in continuous roll forming production, it can lead to large cumulative waste and assembly misalignment. By identifying whether the root cause lies in encoder feedback, motion synchronization, feeding stability, or software calibration, operators can quickly bring the system back to precision.

Whether it’s a roof panel roll forming machine, a C/Z purlin line, a door frame machine, or a PU sandwich panel line, these troubleshooting principles remain consistent — precise measurement, synchronized motion, and stable feeding are the foundation for accurate cutting and smooth production.